A Sturdy And Durable Tubular Scaffolding System

Product description

The high-strength octagonal disk lock design is compatible with standard parts, diagonal braces, jacks and other components, providing flexible and stable construction support. Made of Q355/Q235 steel, it supports hot-dip galvanizing, painting and other treatments, has strong corrosion resistance, and is suitable for construction, bridge and other projects.

With a monthly production capacity of over 60 containers, we mainly sell to the Vietnamese and European markets. Our products are of high quality and low price, and we offer professional packaging and delivery.

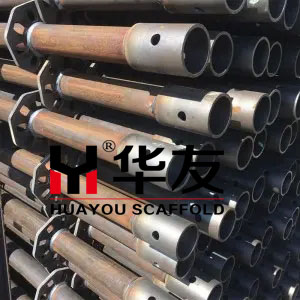

Octagonlock Standard

The OctagonLock standard is the core vertical support component of the octagonal lock scaffold system. It is made of high-strength Q355 steel pipes (Ø48.3×3.25/2.5mm) welded with 8/10mm thick Q235 octagonal plates, and reinforced at intervals of 500mm to ensure ultra-high load-bearing capacity and stability.

Compared with the traditional pin connection of the ring lock bracket, the OctagonLock standard adopts 60×4.5×90mm sleeve socket welding, providing faster and more secure modular assembly, and is suitable for harsh construction environments such as high-rise buildings and Bridges.

|

No. |

Item |

Length(mm) |

OD(mm) |

Thickness(mm) |

Materials |

|

1 |

Standard/Vertical 0.5m |

500 |

48.3 |

2.5/3.25 |

Q355 |

|

2 |

Standard/Vertical 1.0m |

1000 |

48.3 |

2.5/3.25 |

Q355 |

|

3 |

Standard/Vertical 1.5m |

1500 |

48.3 |

2.5/3.25 |

Q355 |

|

4 |

Standard/Vertical 2.0m |

2000 |

48.3 |

2.5/3.25 |

Q355 |

|

5 |

Standard/Vertical 2.5m |

2500 |

48.3 |

2.5/3.25 |

Q355 |

|

6 |

Standard/Vertical 3.0m |

3000 |

48.3 |

2.5/3.25 |

Q355 |

Our advantages

1. Super strong structural stability

It features an innovative dual contact surface of octagonal discs and U-shaped grooves, forming a triangular mechanical structure. The torsional stiffness is 50% higher than that of traditional ring lock scaffolding

The edge limit design of the 8mm/10mm thick Q235 octagonal disc completely eliminates the risk of lateral displacement

2. Revolutionary and efficient assembly

The pre-welded sleeve socket (60×4.5×90mm) can be directly connected, which increases the assembly speed by 40% compared with the ring lock pin type

Eliminating redundant components such as base rings reduces the rate of accessory wear by 30%

3. Ultimate anti-drop safety

The patented curved hook wedge pin three-dimensional locking has an anti-vibration detachment performance far exceeding that of direct sales designs

All connection points are protected by both surface contact and mechanical pins

4. Military-grade material support

The main vertical poles are made of Q355 high-strength steel pipes (Ø48.3×3.25mm).

Supports hot-dip galvanizing (≥80μm) treatment and has a salt spray test duration of over 5,000 hours

It is particularly suitable for scenarios with strict stability requirements such as super high-rise buildings, large-span Bridges, and power plant maintenance

FAQ

Q1. What is the Octagonal Lock Scaffolding System?

The Octagonal Lock Scaffolding System is a modular scaffolding system that includes components such as Octagonal Scaffolding Standards, Beams, Braces, Base Jacks and U-Head Jacks. It is similar to other scaffolding systems such as the Disc Lock Scaffolding and Layher System.

Q2. What components does the Octagonal Lock Scaffolding System include?

The Octagonal Lock Scaffolding System consists of various components including:

- Octagonal scaffolding standard

- Octagonal Scaffolding Account Book

- Octagonal scaffolding diagonal brace

- Base jack

- U-Head Jack

- Octagonal plate

- Ledger Head

- Wedge pins

Q3. What are the surface treatment methods for the Octagonal Lock Scaffolding System?

We offer a variety of surface finish options for the Octagonlock Scaffolding System including:

- Painting

- Powder coating

- Electrogalvanizing

- Hot-dip galvanized (the most durable, corrosion-resistant option)

Q4. What is the production capacity of the Octagonal Lock Scaffolding System?

Our professional factory has a strong production capacity and can produce up to 60 containers of Octagonal Lock Scaffolding System components per month.