Adjustable Scaffolding Steel Prop Provide Reliable Support

Professional, safe and efficient adjustable scaffolding support columns

Our scaffolding steel pillars (also known as support columns, top braces, or telescopic pillars) are an ideal solution for supporting formwork, beams, and concrete structures in modern construction. With its outstanding strength, adjustable flexibility and long-lasting durability, it has completely replaced traditional wooden pillars, providing solid and reliable safety guarantees for your engineering projects.

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube Dia(mm) |

Outer Tube Dia(mm) |

Thickness(mm) |

Customized |

| Heavy Duty Prop |

1.7-3.0m |

48/60/76 |

60/76/89 |

2.0-5.0 | Yes |

| 1.8-3.2m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.0-3.5m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.2-4.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 3.0-5.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| Light Duty Prop | 1.7-3.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

| 1.8-3.2m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.0-3.5m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.2-4.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

Other Information

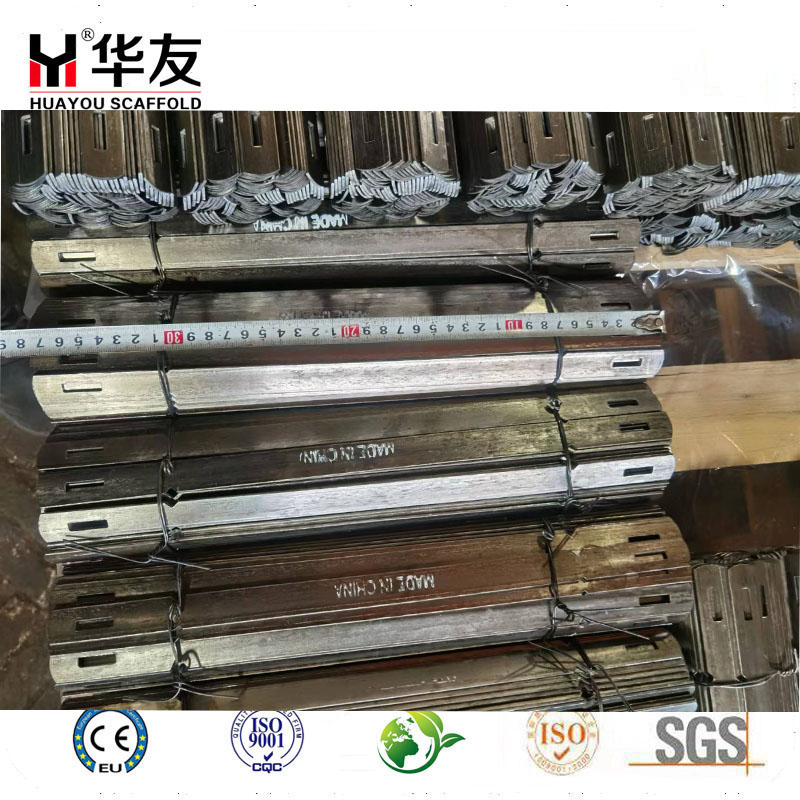

| Name | Base Plate | Nut | Pin | Surface Treatment |

| Light Duty Prop | Flower type/Square type | Cup nut/norma nut | 12mm G pin/ Line Pin | Pre-Galv./Painted/

Powder Coated |

| Heavy Duty Prop | Flower type/Square type | Casting/Drop forged nut | 14mm/16mm/18mm G pin | Painted/Powder Coated/

Hot Dip Galv. |

Advantages

1. Outstanding load-bearing capacity and structural safety

High-strength materials: Made of high-quality steel pipes, especially for heavy-duty supports, larger diameters (such as OD60mm, 76mm, 89mm) and thicker wall thicknesses (usually ≥2.0mm) are used, which endows it with extremely high compressive strength and stability, and its load-bearing capacity far exceeds that of traditional wood.

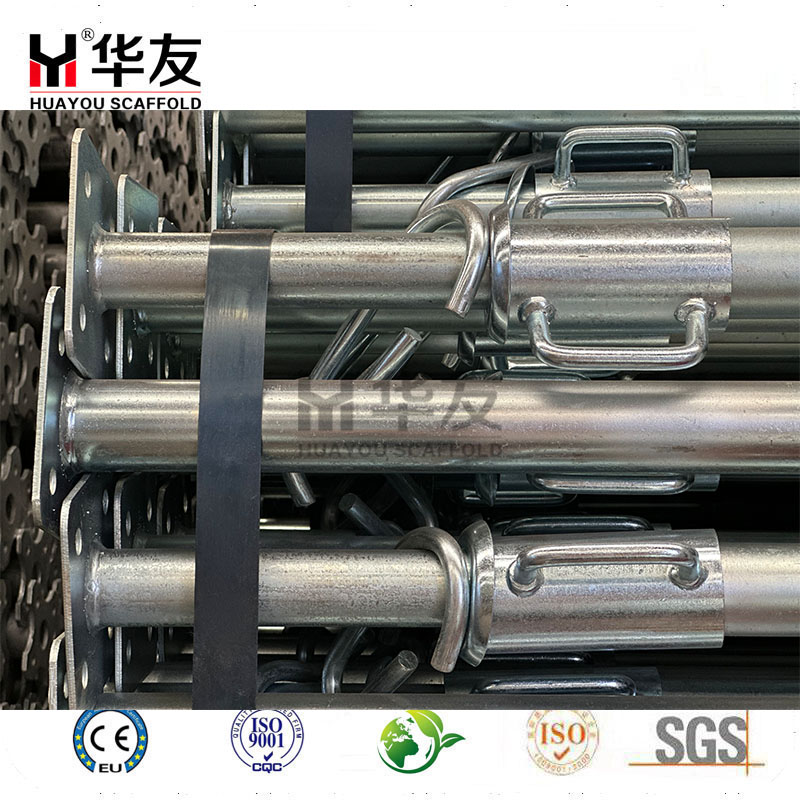

Sturdy connecting parts: Heavy-duty supports are made of cast or forged nuts, which are of high strength, less prone to deformation or slippage, ensuring the safety and reliability of the support system under heavy loads.

Historical comparison: It has completely solved the problems of easy breakage and decay of early wooden supports, providing a solid and safe support for concrete pouring and greatly reducing construction risks.

2. Excellent durability and economy

Long service life: Steel itself has high strength, is corrosion-resistant, and is not prone to damage like wood due to moisture, insect infestation or repeated use.

Multiple surface treatments: We offer treatment methods such as painting, pre-galvanizing, and electro-galvanizing, effectively preventing rust and extending the product's service life. Even in harsh construction site environments, it remains durable for a long time.

Reusable: Its robust and durable nature enables it to be recycled multiple times in various projects, reducing the cost per use. The long-term economic benefits are significantly higher than those of consumable wooden supports.

3. Flexible adjustability and versatility

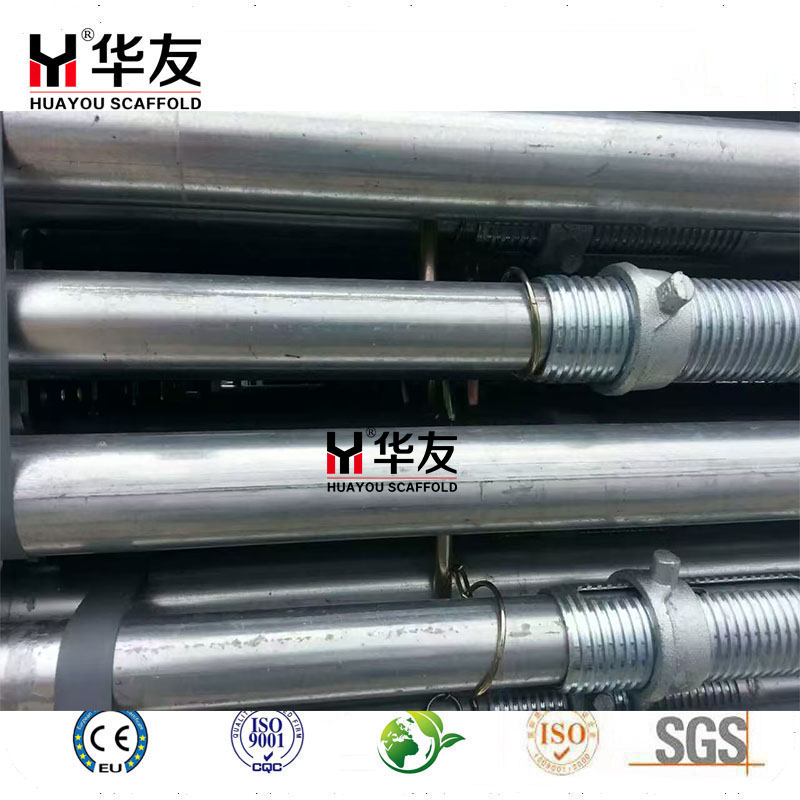

Telescopic and adjustable design: It adopts a telescopic structure with inner and outer tubes nested, and the height can be flexibly adjusted, which can quickly adapt to the requirements of different floor heights, beam bottom elevations and formwork supports.

Wide application scenarios: Mainly used for supporting formwork, beams and other panels, providing precise and stable temporary support for concrete structures, suitable for various building structures and construction stages.

A variety of specifications are available: from light duty (OD40/48mm, OD48/57mm) to heavy duty (OD48/60mm, OD60/76mm, etc.), the product series is complete and can meet the different load requirements from light to heavy.

4. Convenient construction efficiency

Quick and easy installation: With a simple structure and convenient operation, the height can be fine-tuned and locked easily by adjusting the nut, which greatly saves installation and disassembly time and improves the overall construction efficiency.

Moderate weight for easy handling: The light duty support design makes it lightweight. Even with heavy duty support, its modular design facilitates manual handling and turnover, enhancing the efficiency of on-site material management.

FAQS

1. What is a Scaffolding Steel Prop, and what is it used for?

A Scaffolding Steel Prop, also known as a shoring prop, telescopic prop, or Acrow jack, is an adjustable steel support column. It is primarily used in construction to support formwork, beams, and plywood for concrete structures. It provides a strong, safe, and adjustable alternative to traditional wooden poles.

2. What are the main types of Scaffolding Steel Props?

There are two main types:

Light Duty Prop: Made from smaller diameter pipes (e.g., OD 40/48mm, 48/57mm), featuring a lighter "cup nut." They are generally lighter in weight.

Heavy Duty Prop: Made from larger and thicker pipes (e.g., OD 48/60mm, 60/76mm, 76/89mm), with a heavier casting or drop-forged nut. These are designed for higher load capacities.

3. What are the advantages of using steel props over traditional wood poles?

Steel props offer significant advantages:

Safer: Higher loading capacity and less prone to sudden failure.

More Durable: Not susceptible to rotting or breaking easily like wood.

Adjustable: Can be extended or retracted to suit different height requirements.

4. What surface treatments are available for Light Duty Props?

Light Duty Props are typically available with several surface treatments to prevent rust, including:

Painted

Pre-galvanized

Electro-galvanized

5. How can I identify a Heavy Duty Prop?

Heavy Duty Props can be identified by several key features:

Larger Pipe Diameter and Thickness: Using pipes like OD 48/60mm, 60/76mm, etc., with a thickness usually above 2.0mm.

Heavier Nut: The nut is a substantial casting or drop-forged component, not a light cup nut.