Durable Ringlock Scaffolding Horizontal And Diagonal Bracing Solutions

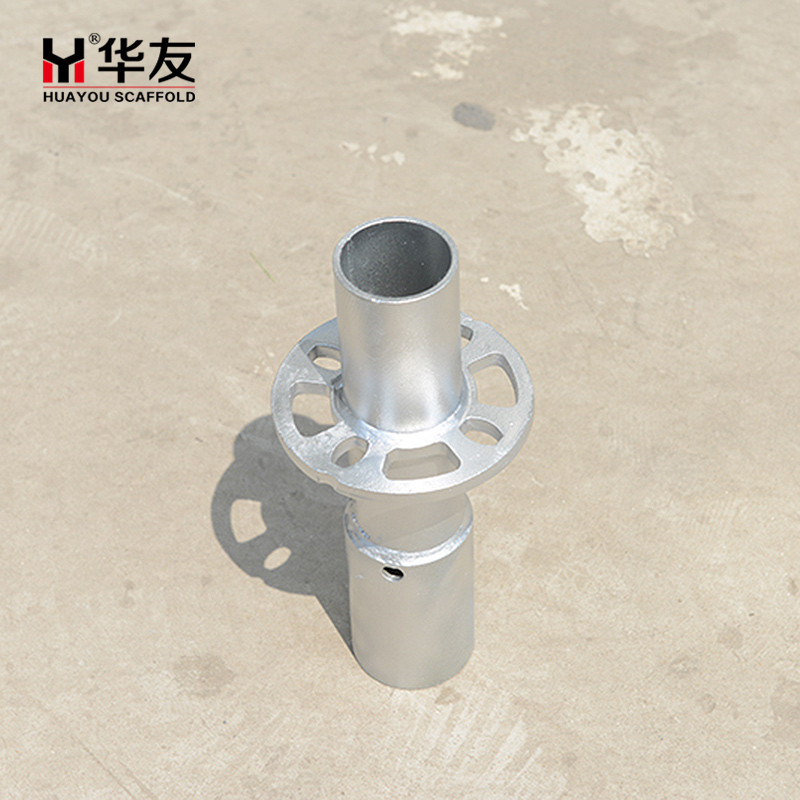

Ringlock ledgers serve as crucial horizontal connectors within the ringlock scaffolding system, linking vertical standards together. Their length is defined as the center-to-center distance between two standards, with common sizes including 0.39m, 0.73m, 1.4m, and up to 3.07m, while custom lengths are also available. Each ledger consists of a steel pipe, typically OD48mm or OD42mm, welded with two cast ledger heads at both ends. Connection is secured by driving a lock wedge pin into the rosette on the standard. Although not the primary load-bearing component, the ledger is indispensable for forming a complete and stable scaffold structure. Available in various ledger head designs, including wax mold and sand mold types, these components can be tailored to meet specific project requirements.

Size as following

|

Item |

OD (mm) |

Length (m) |

THK (mm) |

Raw Materials |

Customized |

|

Ringlock Single Ledger O |

42mm/48.3mm |

0.3m/0.6m/0.9m/1.2m/1.5m/1.8m/2.4m |

1.8mm/2.0mm/2.5mm/2.75mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

42mm/48.3mm |

0.65m/0.914m/1.219m/1.524m/1.829m/2.44m |

2.5mm/2.75mm/3.0mm/3.25mm | STK400/S235/Q235/Q355/STK500 | YES | |

|

48.3mm |

0.39m/0.73m/1.09m/1.4m/1.57m/2.07m/2.57m/3.07m/4.14m |

2.5mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

|

Size can be customerized |

|||||

The advantages of ringlock scaffolding

1. Flexible configuration and wide application

Adopting modular design, with standardized node spacing of 500mm/600mm, it can be quickly combined with components such as vertical rods and diagonal braces, meeting diverse engineering requirements such as bridge support, exterior wall scaffolding, and stage frame structures. It supports customized length and connection head design.

2. Stable structure, safe and reliable

The crossbar is self-locking connected with the vertical bar disk buckle through wedge-shaped lock pins, forming a stable triangular force-bearing system. The horizontal rods and vertical supports work in synergy to effectively distribute the load and ensure the rigidity of the overall structure. It is equipped with a dedicated hook pedal and a safety ladder cage to further enhance construction safety protection.

3. Exquisite craftsmanship and long-lasting durability

It adopts the hot-dip galvanizing overall surface treatment process, which has excellent anti-corrosion performance, avoids the problems of paint layer peeling and rusting, extends the service life to 15-20 years, and significantly reduces maintenance costs.

4. Easy to assemble and disassemble, economical and efficient

The system structure is simple, with less steel consumption, effectively reducing material and transportation costs. The modular design increases installation efficiency by more than 50%, significantly reducing labor and time costs. It is particularly suitable for engineering projects that require rapid assembly.

5. Precision components, customized services

The crossbar head is made by two processes: investment casting and sand casting. It offers multiple specifications ranging from 0.34kg to 0.5kg. Special lengths and connection forms can be customized according to customer drawings to ensure perfect compatibility with the system.

Basic information

Huayou - A professional manufacturer and supplier of scaffolding systems

Huayou is a manufacturing enterprise specializing in the research and development and production of scaffolding systems. Our core mission is to provide safe, durable and efficient construction support solutions.