Durable Scaffolding Props And Jacks For Reliable Support

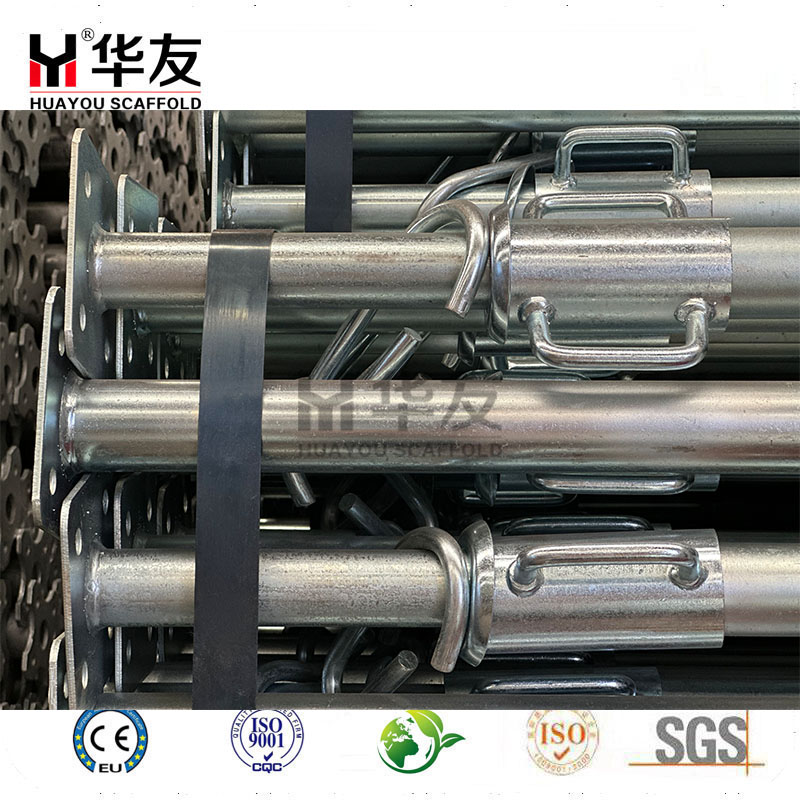

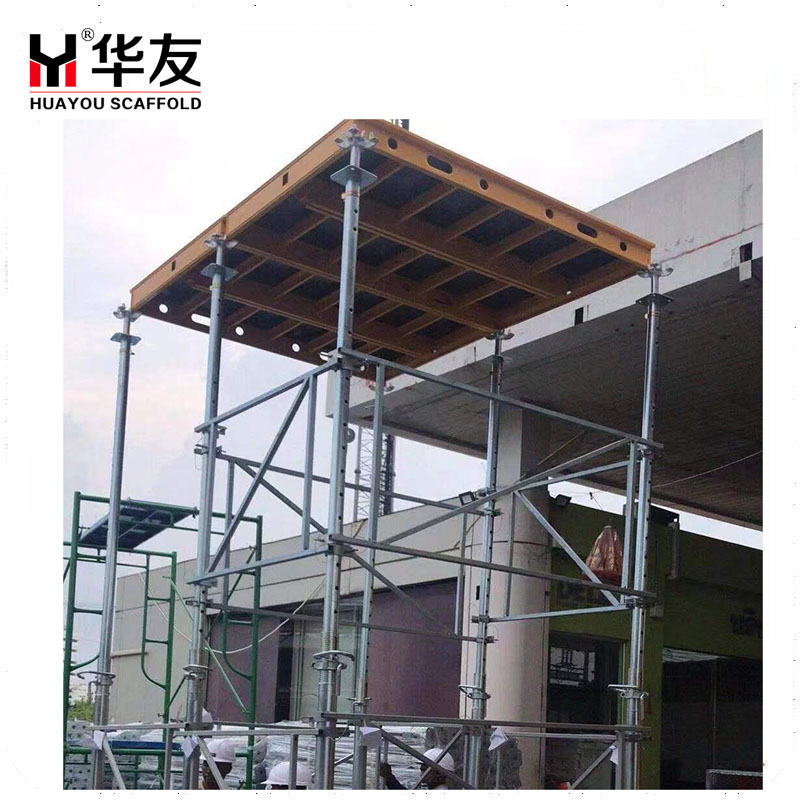

The four-column fork head jack is a core load-bearing component in the scaffolding system. It adopts an integrated design of high-strength Angle steel and reinforced base plate, ensuring a stable and durable structure. Specifically designed for connecting H-shaped steel supports and formwork systems, it can effectively transfer loads, ensure the overall rigidity of the scaffolding and construction safety, and is suitable for the support requirements of various concrete pouring projects.

Product Parameters

| Name | Pipe Dia mm | Fork size mm | Surface Treatment | Raw materials | Customized |

| Fork Head | 38mm | 30x30x3x190mm, 145x235x6mm | Hot Dip Galv/Electro-Galv. | Q235 | Yes |

| For Head | 32mm | 30x30x3x190mm, 145x230x5mm | Black/Hot Dip Galv/Electro-Galv. | Q235/#45 steel | Yes |

Core advantages

1. High-strength material, reliable load capacity

Made of high-quality and high-strength steel, it matches the performance of scaffolding support materials to ensure excellent compressive and load-bearing capacity, meeting the stability requirements under harsh working conditions.

2. Four corners are reinforced to prevent loosening and earthquake resistance

The unique four-column structure, combined with the reinforced node design, significantly enhances the connection tightness, effectively preventing component displacement or loosening during construction and extending the overall system's service life.

3. Quick installation, saving time and effort

The modular design makes the installation process more convenient. Assembly and adjustment can be completed quickly without complex tools, significantly improving the efficiency of scaffolding erection and shortening the construction period.

4. Compliance and security, certification guarantee

The product strictly adheres to the safety regulations for construction and has passed relevant standard tests, providing reliable support for high-altitude operations and effectively ensuring the safety of construction personnel and the project site.

FAQS

1.What is the main function of the scaffold fork head jack?

The scaffold fork head jack is mainly used to connect H-shaped steel support formwork concrete and is an important pillar component for maintaining the overall stability of the scaffold system. It enhances the connection firmness through a four-corner design, effectively preventing component loosening and ensuring construction safety.

2. Why are scaffolding fork head jacks usually made of high-strength steel?

It is made of high-strength steel to match the steel support materials of the scaffolding and ensure good load-bearing capacity. This material selection can meet the load requirements during construction while ensuring the durability and reliability of the structure.

3. What are the advantages of scaffolding fork head jacks in installation?

It can be installed easily and quickly, significantly improving the efficiency of scaffolding assembly. Its design simplifies the operation steps, saves construction time, and is suitable for construction environments that require frequent assembly and dismantling.

4. What is the significance of the four-corner design for scaffolding fork head jacks?

The four-corner design enhances the firmness of the connection, effectively distributes the load, and prevents the components of the scaffolding from loosening or shifting during use. This design enhances the overall structural stability and reduces safety risks.

5. What standards should a qualified scaffold fork head jack meet?

A qualified fork head jack must comply with relevant construction safety standards and ensure that its design, materials and manufacturing processes meet industry norms. This provides a reliable guarantee for the safe operation of workers on scaffolding and avoids accidents caused by component failure.