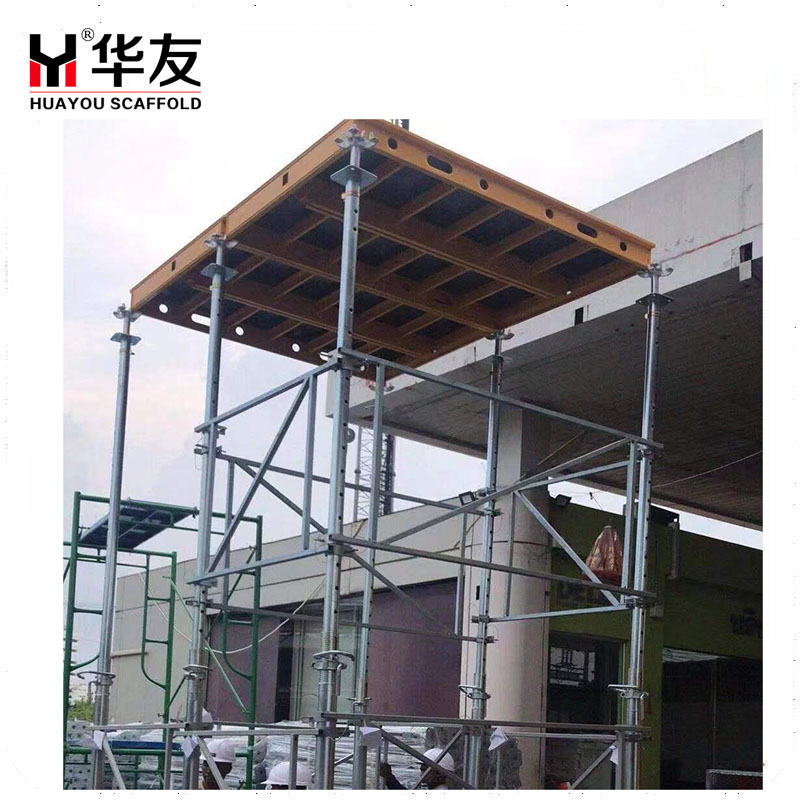

Durable scaffolding supports and jacks provide reliable support

Based on high-strength steel, our scaffolding fork head jack ensures superior load-bearing capacity and overall system stability. It features a robust four-pillar design for a firmer connection, effectively preventing loosening during use. Manufactured with precision laser cutting and strict welding standards, every unit guarantees zero faulty welds and no spatter. Compliant with safety regulations, it enables quick installation and provides reliable safety assurance for workers.

Specification Details

| Name | Pipe Dia mm | Fork size mm | Surface Treatment | Raw materials | Customized |

| Fork Head | 38mm | 30x30x3x190mm, 145x235x6mm | Hot Dip Galv/Electro-Galv. | Q235 | Yes |

| For Head | 32mm | 30x30x3x190mm, 145x230x5mm | Black/Hot Dip Galv/Electro-Galv. | Q235/#45 steel | Yes |

Advantages

1. Stable structure and high safety

Four-column reinforced design: Four Angle steel pillars are welded to the base plate to form a stable support structure, significantly enhancing the connection firmness.

Preventing loosening: Effectively prevent the components of scaffolding from loosening during use, ensuring the stability of the overall system and meeting building safety standards.

2. High-quality materials with strong load-bearing capacity

High-strength steel: High-strength steel that matches the scaffolding support system is selected to ensure excellent load-bearing capacity and structural durability.

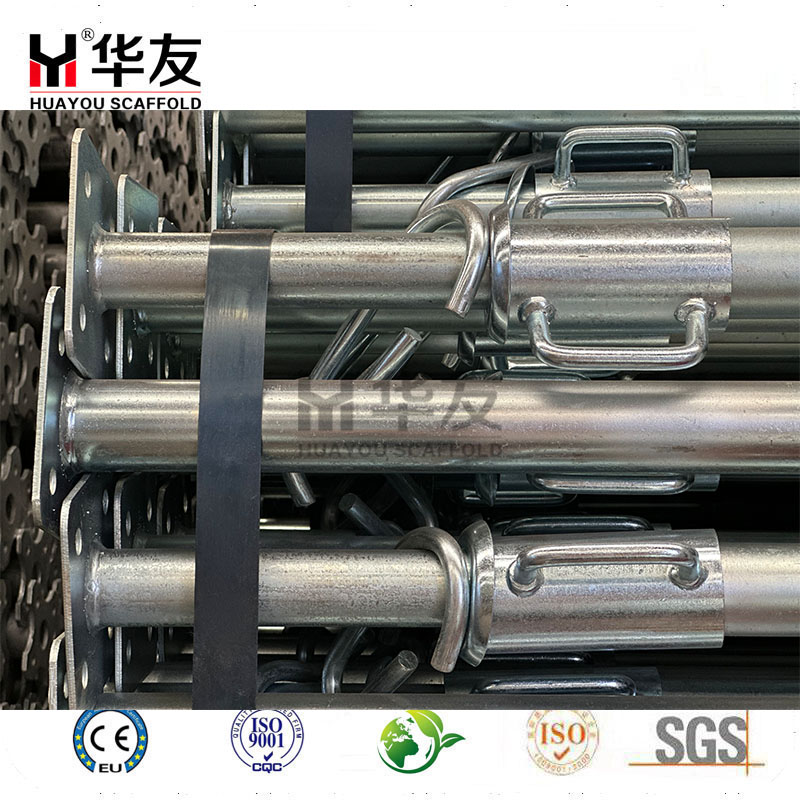

3. Precision manufacturing, reliable quality

Strict incoming material inspection: Conduct strict tests on the grade, diameter and thickness of steel materials.

Laser precise cutting: Using a laser cutting machine for material cutting, the tolerance is controlled within 0.5mm to ensure the accuracy of the components.

Standardized welding process: The welding depth and width are both carried out in accordance with the factory's high standards to ensure uniform and consistent weld seams, free of defective welds, missed welds, spatter and residue, and to guarantee the strength and reliability of the welded joints.

4. Easy installation, improving efficiency

The design is convenient for quick and easy installation, which helps to improve the overall erection efficiency of scaffolding and save working hours.