Durable Steel Props Support Solutions For Construction Projects

We specialize in manufacturing adjustable steel pillars for scaffolding, completely eliminating the potential risks of traditional wooden poles being prone to breakage and decay. The product, relying on high-precision laser drilling technology and the exquisite craftsmanship of experienced workers, ensures outstanding load-bearing performance and flexible adjustment capability. All materials have passed strict quality inspection, dedicated to providing safe, solid and durable support guarantees for all kinds of formwork and concrete structure projects.

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube Dia(mm) |

Outer Tube Dia(mm) |

Thickness(mm) |

Customized |

| Heavy Duty Prop |

1.7-3.0m |

48/60/76 |

60/76/89 |

2.0-5.0 | Yes |

| 1.8-3.2m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.0-3.5m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.2-4.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 3.0-5.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| Light Duty Prop | 1.7-3.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

| 1.8-3.2m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.0-3.5m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.2-4.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

Other Information

| Name | Base Plate | Nut | Pin | Surface Treatment |

| Light Duty Prop | Flower type/Square type | Cup nut/norma nut | 12mm G pin/ Line Pin | Pre-Galv./Painted/

Powder Coated |

| Heavy Duty Prop | Flower type/Square type | Casting/Drop forged nut | 14mm/16mm/18mm G pin | Painted/Powder Coated/

Hot Dip Galv. |

Advantages

1. Excellent load-bearing capacity and safety

Compared with traditional wooden poles that are prone to breakage and decay, steel pillars have higher strength, better load-bearing capacity and excellent durability, providing safe and reliable support for concrete pouring.

2. Flexible adjustability and versatility

The height of the pillar can be flexibly adjusted to meet the requirements of different construction heights. The product has a wide range of applications and is also known as a support, telescopic pillar, jack, etc. It is suitable for supporting concrete structures under formwork, beams and various types of plywood.

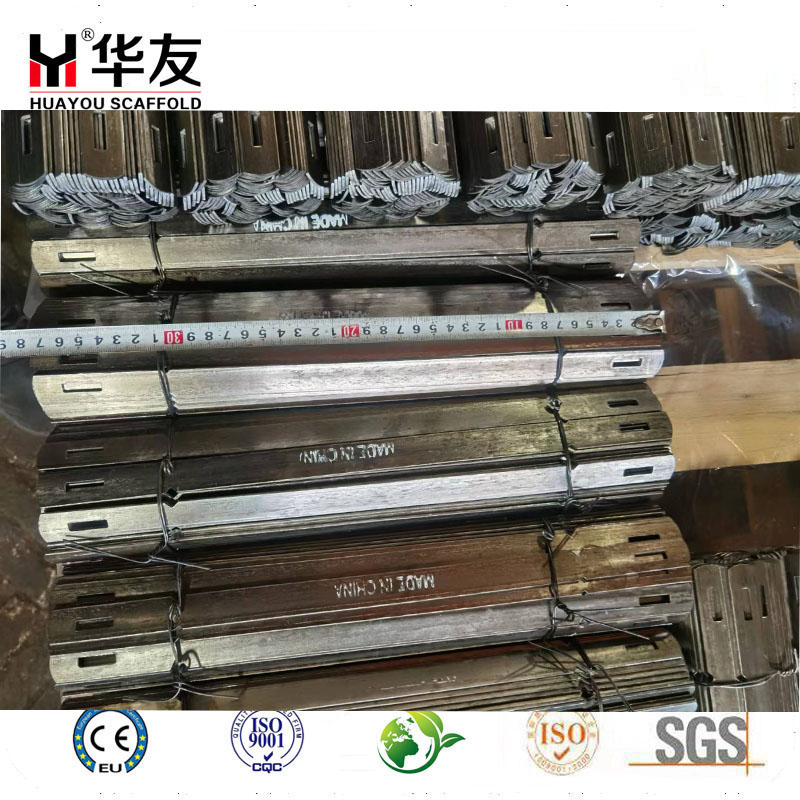

3. Exquisite manufacturing techniques and precision

The inner tubes of the key components are precisely punched by laser, replacing the traditional punching method with a load machine. The hole position accuracy is higher, effectively ensuring the smoothness and structural integrity of the product during adjustment and use.

4. Strict quality control and reliability

Each batch of product materials undergoes strict inspection and testing to ensure they meet the quality standards and requirements of customers.

5. Rich experience and excellent reputation

The core workers have over 15 years of production and processing experience and are constantly improving production technology. Our focus on craftsmanship has earned our products an extremely high reputation among customers.

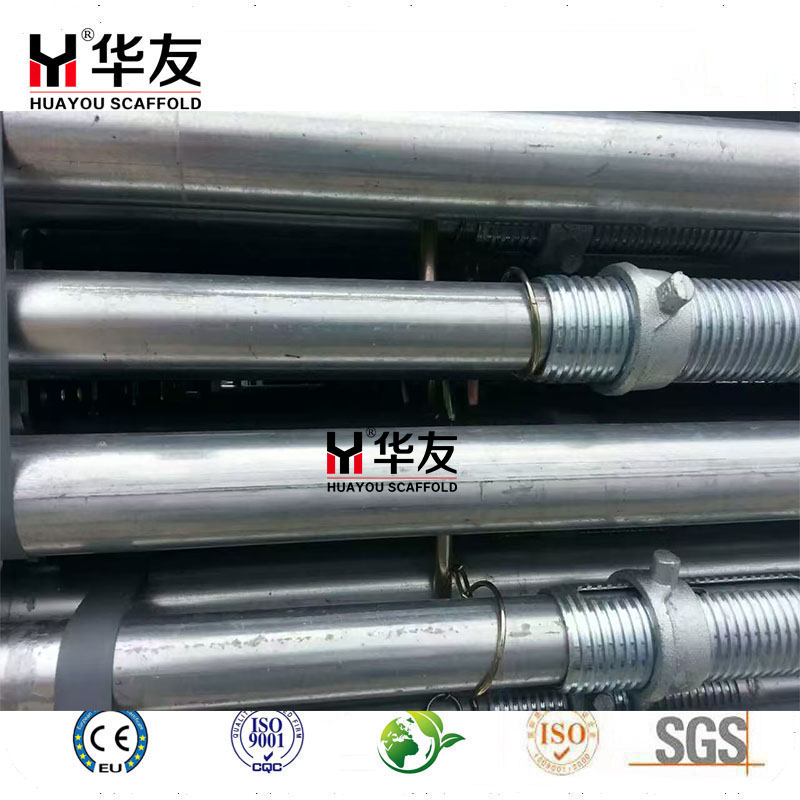

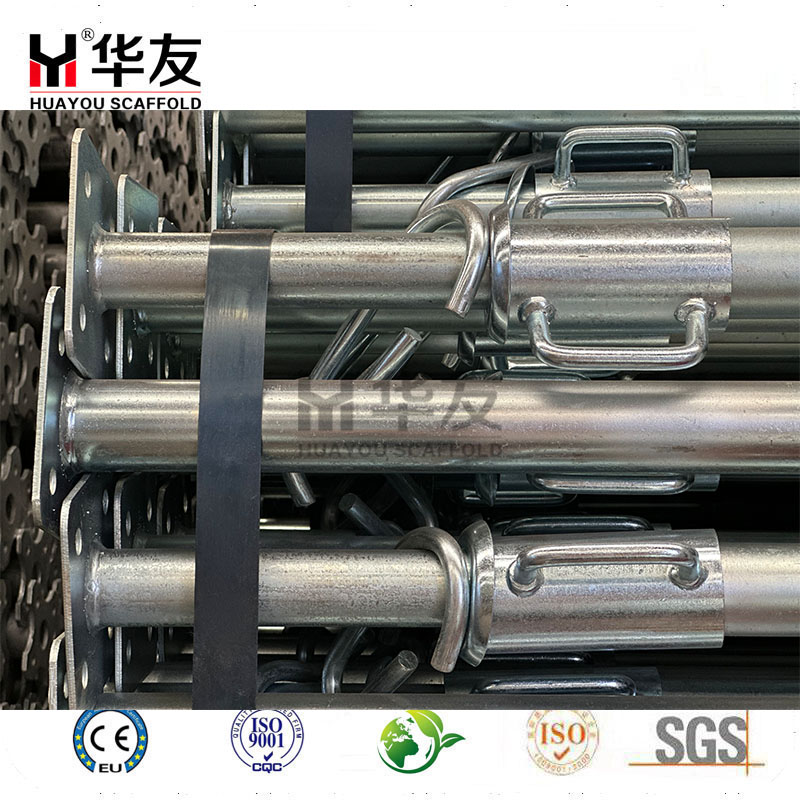

Details Showing

Quality controlling is very important for our production. Please check the follow pictures that just part of our light duty props.

Until now, almost all props type can be produced by our advanced machines and mature workers. You just can show your drawing details and pictures. we can produce for you 100% same with cheap price.

Testing Report

We always put quality control first. As shown in the illustration, this is precisely a microcosm of our production process for lightweight pillars. Our mature production system and professional team have the ability to manufacture a full range of products. As long as you provide your specific requirements, we promise to offer you high-quality products that are exactly the same as the samples at highly competitive prices.