Factory Making Screw Jack Material - Screw Hollow Base Jack: TJHY-SJH1 – Huayou

Factory Making Screw Jack Material - Screw Hollow Base Jack: TJHY-SJH1 – Huayou Detail:

Adjustable hollow jack base is made by seamless pipe mostly, some also made by welding pipe. The thickness is 4-5mm, and consist of screw bar, base plate and nut. Hollow jacks usded in engineering construction scaffolding, bridge construction scaffolding,especially used with modular scaffoling system like ringlock scaffolding system, cuplock system, kwikstage scaffolding etc.

Hollow screw jacks also divided into two types: Hollow jacks base and Hollow U head jacks. They are play the role of top and bottom support.

Hollow jack base

Scaffolding screw jack is a new building material, and it is an important accessory to provide support and end-to-end connection for construction work. Its role is transfer and adjustment for the overall lifting of the building stress.

Basic information

1.Brand: Huayou

2.Materials: Q235 pipe, seamless pipe

3.Surface treatment: hot dipped galvanized , electro-galvanized, painted, powder coated.

4.Production procedure: material—cut by size—screwing—welding —surface treatment

5.Package: by pallet

6.MOQ: 15Ton

7.Delivery time: 20-30days depends on the quantity

Size as following

|

Item |

Screw Bar (OD*Thk*Length) |

Base Plate |

|

Hollow Base Jack |

38*4.0/5.0*600mm, |

140*140*5mm |

|

38*4.0/5.0*600mm, |

150*150*6mm |

|

|

48*4.0/5.0*600mm, |

140*140*5mm |

|

|

48*4.0/5.0*600mm, |

150*150*6mm |

|

|

Hollow Base Jack U head |

38*4.0/5.0*600mm, |

150*120*50*5mm |

|

38*4.0/5.0*600mm, |

170*130*50*5mm |

|

|

48*4.0/5.0*600mm, |

150*120*50*5mm |

|

|

48*4.0/5.0*600mm, |

170*130*50*5mm |

Company advantages

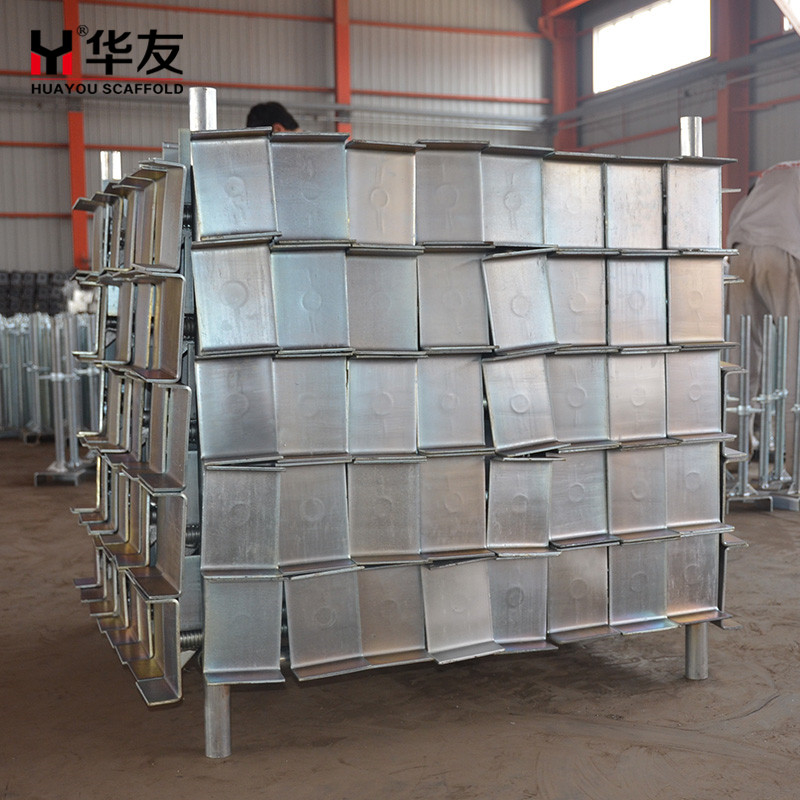

We are now have one workshop for pipes with two production lines and one workshop for ringlock system’s production which including 18 sets automatic welding equipment. And then three product lines for metal plank, two lines for steel prop , etc. 5000 tons scaffolding products were produced in our factory and we can provide fast delivery to our clients.

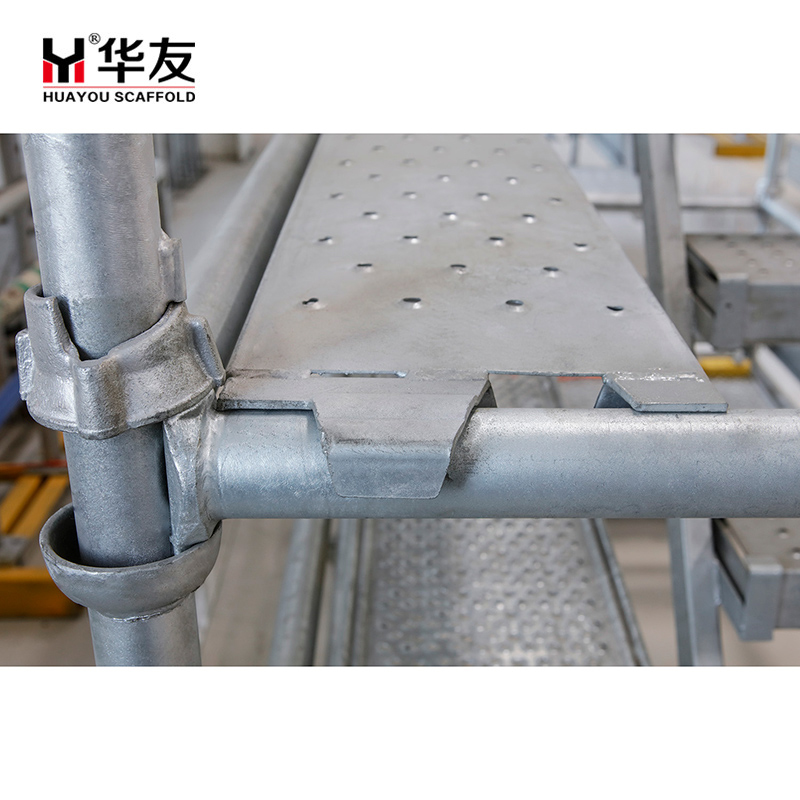

Product detail pictures:

Related Product Guide:

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Factory Making Screw Jack Material - Screw Hollow Base Jack: TJHY-SJH1 – Huayou , The product will supply to all over the world, such as: United States, Iraq, Rwanda, We are introduced as a one of the growing manufacture supplier and export of our products. We have a team of dedicated trained professional who take care the quality and timely supply. If you are looking for Good Quality at a good price and timely delivery. Do contact us.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.