H Timber Beam Provides Strong Structural Support

Product Introduction

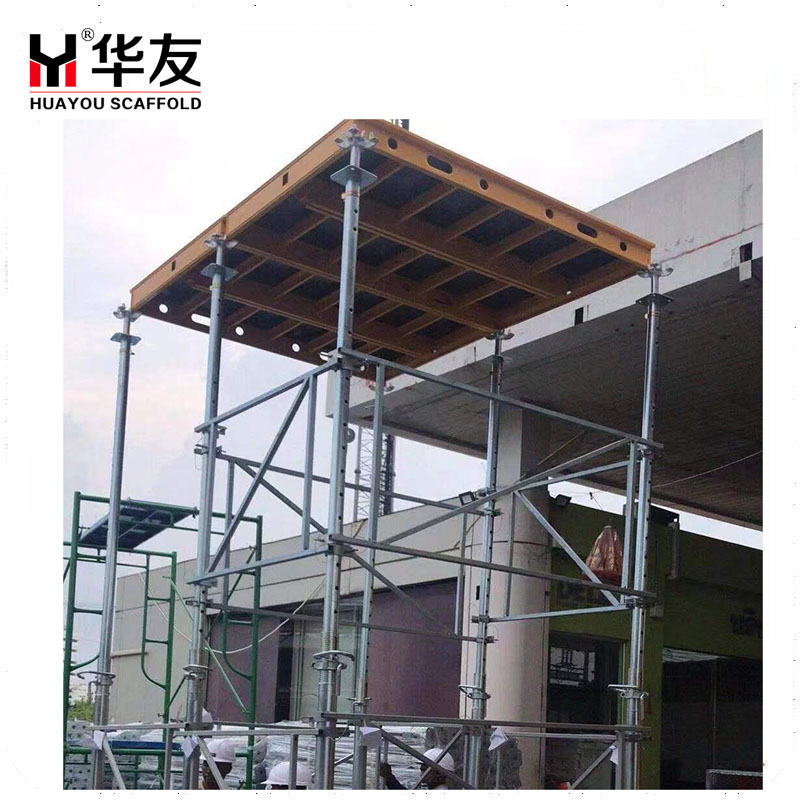

Also known as an I-beam or H-beam, this innovative product is designed to provide strong structural support while being cost-effective for light-load projects. While traditional H-beams are known for their high load-bearing capacity, our Wood H-beams offer you a practical alternative that helps you save money without compromising on quality.

Crafted from premium wood, wooden H20 beam offer exceptional strength and durability. Their unique design distributes loads efficiently, making them ideal for a variety of construction applications, from residential buildings to commercial projects. Whether you need to support a roof, floor, or other structural member, our H beams ensure stability and reliability.

Company Advantage

Our company is committed to expanding our business scope and providing first-class products to customers around the world. Since the establishment of our export company in 2019, we have successfully built a strong procurement system to serve customers in nearly 50 countries. Our persistent pursuit of quality and customer satisfaction makes us a trusted partner in the construction industry.

H Beam Information

|

Name |

Size |

Materials |

Length( m) |

Middle Bridge |

|

H Timber Beam |

H20x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

H16x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

|

H12x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

H Beam/I Beam Features

1. I-beam is an important component of the internationally used building formwork system. It has the characteristics of light weight, high strength, good linearity, not easy to deform, surface resistance to water and acid and alkali, etc. It can be used all year round, with low cost amortization expenses; it can be used with professional formwork system products at home and abroad.

2. It can be widely used in various formwork systems such as horizontal formwork system, vertical formwork system (wall formwork, column formwork, hydraulic climbing formwork, etc.), variable arc formwork system and special formwork.

3. The wooden I-beam straight wall formwork is a loading and unloading formwork, which is easy to assemble. It can be assembled into formworks of various sizes within a certain range and degree, and is flexible in application. The formwork has high rigidity, and it is very convenient to connect the length and height. The formwork can be poured at a maximum of more than ten meters at a time. Because the formwork material used is light in weight, the whole formwork is much lighter than the steel formwork when assembled.

4. The system product components are highly standardized, have good reusability, and meet environmental protection requirements.

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.4 | Electro-Galv. |

| Round nut |  |

15/17mm | 0.45 | Electro-Galv. |

| Round nut |  |

D16 | 0.5 | Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | Electro-Galv. | |

| Washer |  |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

Product Advantage

One of the main advantages of H Timber Beam is their light weight, making them ideal for light-load projects. Unlike traditional steel H-beams, which are designed for high load-bearing capacity, wooden beams can significantly reduce costs without compromising quality. Wooden beams are an attractive option for builders who want to save on material costs while achieving a reliable structure.

In addition, wooden beams are generally easier to handle and install, which can reduce labor costs and speed up project completion time.

Another benefit is environmental protection. Wood beams are derived from renewable resources, making them a more sustainable option than steel. This fits in with the growing trend toward eco-friendly building practices, appealing to environmentally conscious builders and clients alike.

Product shortcoming

One notable disadvantage is their susceptibility to moisture and insect damage. Unlike steel, wood can warp, rot, or become infested by insects if not properly treated and maintained. This can lead to long-term structural issues if the beams are not adequately protected.

FAQS

Q1:What are wooden H20 beams?

The Wooden H20 Beam is an engineered wood beam designed for construction purposes. Its unique H-shaped structure offers excellent load-bearing capacity while being lightweight, making it ideal for projects that do not require the use of heavy steel beams.

Q2:Why choose wooden H beams instead of steel beams?

While H-beams are known for their high load-bearing capacity, they are expensive and may not be necessary for lighter projects. Wood H-beams are a more economical alternative without compromising on strength and durability. This makes them a popular choice for residential construction, temporary structures, and other lightweight applications.

Q3:How does your company support customers in the wooden beam market?

Since establishing our export company in 2019, we have expanded our business to nearly 50 countries around the world. We are committed to quality and customer satisfaction, and have established a complete procurement system to ensure that our customers receive the best products and services that meet their specific needs.