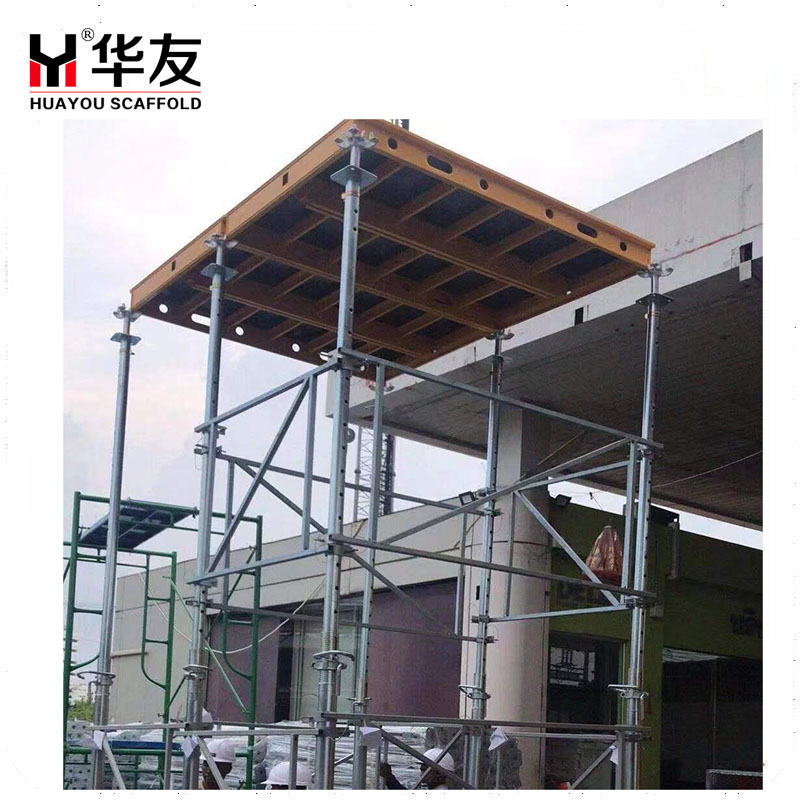

Heavy-Duty Formwork Props For Concrete Slab & Beam Support

This set of heavy-duty steel supports, made of high-strength Q235 or Q355 steel pipes, are vertical adjustable pillars used in concrete formwork projects. Their telescopic design enables flexible adjustment of different closed and open heights through the cooperation of the inner tube, outer tube and locking pins, to meet various construction support requirements. All components, including H-shaped steel and tripod accessories, have undergone powder coating or hot-dip galvanizing for rust prevention, ensuring durability and high load-bearing capacity. To ensure the stability of the entire support system, steel pipes and fasteners can be used for horizontal connection and reinforcement. The product also offers customized services for tripod sizes and fork heads and other accessories according to specific project needs.

Size as following

|

Item |

Min.-Max. |

Inner Tube(mm) |

Outer Tube(mm) |

Thickness(mm) |

|

Heany Duty Prop |

1.8-3.2m |

48/60 |

60/76 |

1.8-4.75 |

|

2.0-3.6m |

48/60 |

60/76 |

1.8-4.75 |

|

|

2.2-3.9m |

48/60 |

60/76 |

1.8-4.75 |

|

|

2.5-4.5m |

48/60 |

60/76 |

1.8-4.75 |

|

|

3.0-5.5m |

48/60 |

60/76 |

1.8-4.75 |

Advantages

High Load Capacity & Durability: Constructed from high-tensile strength steel (Q235/Q355) with anti-rust powder coating or hot-dip galvanization, our steel props provide superior strength and long-lasting performance for demanding concrete projects.

Fully Adjustable & Flexible: Designed as a telescopic system with closed and open height adjustments, these props offer versatile support for various formwork heights, ensuring precise and adaptable shoring on site.

Stable & Integrated System: When combined with tripods, H-beams, and coupler-connected horizontal pipes, the system delivers exceptional stability and reliable high-load support, keeping the entire formwork structure secure.

Basic information

Brand: Huayou

Primary Materials: High-strength Q235 & Q355 steel pipe

Surface Options: Hot-dip galvanized, electro-galvanized, painted, or powder coated

Key Process Steps: Material cutting, hole punching, welding, and surface finishing

Standard Packaging: Bundled with steel strapping or loaded on pallets

Lead Time: Approximately 20-30 days, varying with order quantity

FAQS

1. Q: What is the primary function and main composition of your Steel Prop?

A: Our Steel Prop is an adjustable vertical support system designed for concrete formwork. A standard set includes an inner tube, outer tube, sleeve, upper/base plates, a nut, and a lock pin, providing reliable and flexible shoring.

2. Q: Why is your Scaffolding System considered heavy-duty and suitable for high loads?

A: The system utilizes high-tensile strength steel pipes (Q235/Q355) for its props and integrates robust components like H-beams and tripods. This design, combined with horizontal bracing, ensures exceptional load-bearing capacity for demanding concrete projects.

3. Q: How is your prop adjusted to the required height, and what are its common names?

A: The prop is telescopic, adjustable between its closed and open heights to fit various site needs. It is commonly known as a Scaffolding Prop, Shoring Jack, Formwork Prop, or Telescopic Prop in the industry.

4. Q: What corrosion protection do you offer for the props and accessories?

A: To ensure longevity, our heavy-duty props are treated with either powder coating or hot-dip galvanization. All accessories are manufactured from high-quality materials to resist rust and withstand harsh site conditions.

5. Q: Can components like the Tripod and Prop Fork Head be customized?

A: Yes. Our Props Shoring Tripod (typically available in heights like 650mm, 750mm, 800mm) and other accessories, such as the Scaffolding Prop Fork Head, can be customized to meet specific project requirements and customer specifications.