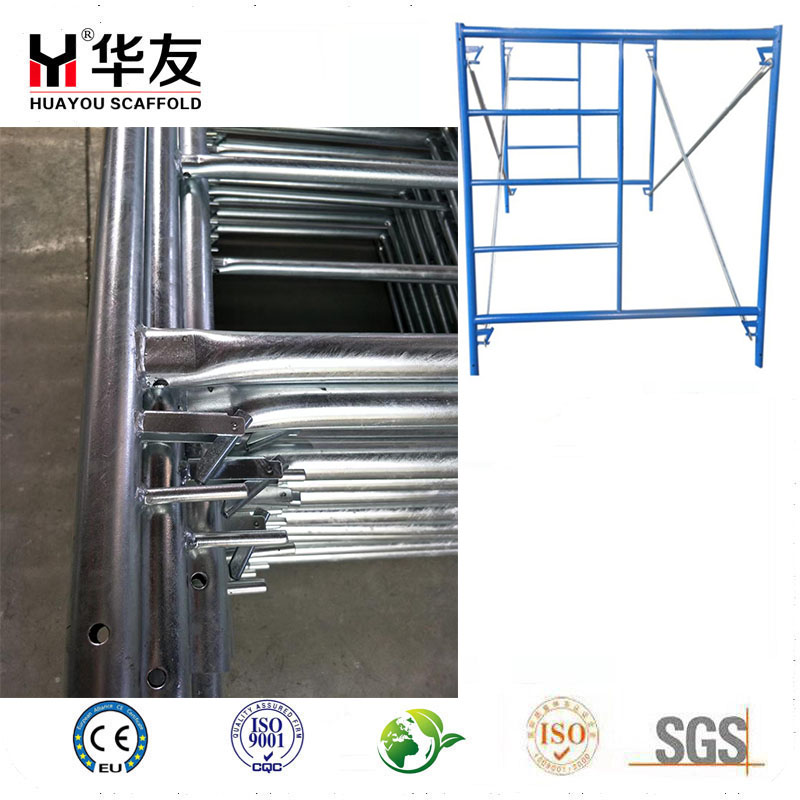

Heavy-Duty Scaffolding Props And Modular Formwork System

Details Showing

The quality in the market varies greatly, and customers often only look at the price. In response to this situation, we offer a tiered solution: For customers pursuing top-of-the-line performance, we recommend a durable model weighing 2.8 kilograms that has undergone annealing treatment. If the demand is moderate, the standard version weighing 2.45 kilograms is already sufficient and has a more favorable price.

| Name | Unit weight kg | Technique Process | Surface Treatment | Raw materials |

| Formwork Casted clamp | 2.45kg and 2.8kg | Casting | Electro-Galv. | QT450 |

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.3kg | Black/Electro-Galv. |

| Wing nut |  |

20/22mm | 0.6kg | Black/Electro-Galv. |

| Round nut with 3 wings |  |

20/22mm, D110 | 0.92kg | Black/Electro-Galv. |

| Round nut with 3 wings |  |

15/17mm, D100 | 0.53 kg / 0.65kg | Black/Electro-Galv. |

| Round nut with 2 wings |  |

D16 | 0.5kg | Black/Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19kg | Black/Electro-Galv. |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | 1kg | Black/Electro-Galv. |

| Washer |  |

100x100mm | Black/Electro-Galv. | |

| Panel lock clamp |  |

2.45kg | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.8kg | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Steel cone |  |

DW15mm 75mm | 0.32kg | Black/Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

Advantages

1.Customized quality, precisely matching market demands

We have a deep understanding of the diverse demands of the global market for quality and price, and thus offer products in multiple grades ranging from the standard 2.45kg model to the high-quality 2.8kg model. Relying on the industrial advantages of Tianjin, we carefully select raw materials of different steel grades and strictly control the quality to ensure that you can always find the solution with the best cost performance.

2. Full-process quality assurance builds the core of structural safety

As a key component connecting the entire template system, our cast-molded clips are made through a pure raw material melting and casting process, and their structural strength and durability far exceed those of pressed parts. From smelting, annealing to electroplating and precise assembly, we adhere to the principle of "quality first", ensuring that each product provides a reliable core connection and support for concrete buildings.

3. A reliable supplier verified in the global market

Our products have been successfully exported to many regions such as Southeast Asia, the Middle East, Europe and America, and have withstood the tests of different markets. We have always adhered to the concept of "customer first, ultimate service", and are committed to meeting your diverse needs. We promote the establishment of a lasting and win-win cooperative relationship with reliable products and professional services.

FAQS

Q 1: The quality of products in the market varies. How does your company ensure that its products meet the needs of different customers?

A: We are well aware that different markets and projects have varying requirements for quality and cost. Therefore, relying on the local raw material advantages in Tianjin, Tianjin Huayou Scaffolding Co., Ltd. proactively offers graded product solutions: for customers with high standards, we recommend high-quality castings that have undergone annealing treatment and weigh 2.8 kilograms. For budget-sensitive projects, we also offer an economical option weighing 2.45 kilograms to ensure that you always find the most cost-effective solution.

Q 2: In the template system, what are the two main types of clamps? Why are they so important?

A: Formwork clamps are key load-bearing components that connect the entire concrete building formwork system, and their reliability directly affects construction safety and quality. At present, there are mainly two processes on the market: casting and stamping. Our company specializes in the production of casting fixtures. They are made by pouring high-quality molten iron into molds, precise processing and electro-galvanizing treatment. Compared with stamping parts, they have a more complete structure and higher strength, and can better provide stable connection and support for wall molds, plate molds, etc.

Q 3: What is your company's production capacity and market experience like?

A: Our company is located in Tianjin, an industrial hub, and enjoys the advantages of high-quality steel procurement and quality control. We have always adhered to the principle of "Quality First, Customer Supreme, Service Ultimate". Our products have been exported to many markets such as Southeast Asia, the Middle East, Europe and America, and we have accumulated rich international export experience. We are committed to providing suitable products based on your specific needs and promoting mutually beneficial and win-win long-term cooperation.