High-Quality Formwork Clamp Provide Reliable Concrete Support

Tianjin Huayou Casting formwork Clamp, specially designed for steel European standard formwork systems, is the key to ensuring a stable connection between wall formwork and board formwork. Unlike the pressing process, we use pure raw materials, which are melted and then cast into shape, and then refined through grinding and electroplating processes. Located in the industrial base of Tianjin, we are able to strictly select steel and precisely control quality. Every product we export to the world adheres to the principle of "quality first" and is committed to providing reliable support for your concrete construction projects.

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.3kg | Black/Electro-Galv. |

| Wing nut |  |

20/22mm | 0.6kg | Black/Electro-Galv. |

| Round nut with 3 wings |  |

20/22mm, D110 | 0.92kg | Black/Electro-Galv. |

| Round nut with 3 wings |  |

15/17mm, D100 | 0.53 kg / 0.65kg | Black/Electro-Galv. |

| Round nut with 2 wings |  |

D16 | 0.5kg | Black/Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19kg | Black/Electro-Galv. |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | 1kg | Black/Electro-Galv. |

| Washer |  |

100x100mm | Black/Electro-Galv. | |

| Panel lock clamp |  |

2.45kg | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.8kg | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Steel cone |  |

DW15mm 75mm | 0.32kg | Black/Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

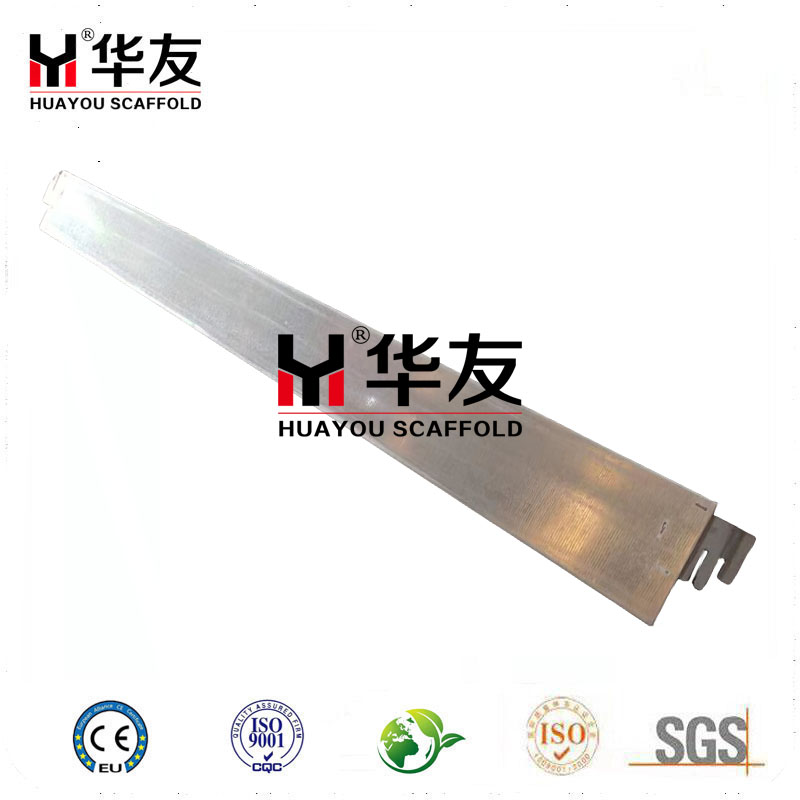

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

FAQS

1.Outstanding structural integrity and load-bearing capacity

Advantage root: The integrated casting process of "heating and melting - casting and forming" is adopted, which makes the metal molecular structure more uniform and dense, with no welding points or splicing seams.

Customer value: It fundamentally eliminates the risk of cracking due to loose welding, can withstand the huge lateral pressure and static load generated during concrete pouring, and provides absolutely reliable safety guarantees for key projects such as high-rise buildings and large-scale infrastructure.

2. Extremely long service life and outstanding durability

Advantage root: High-quality pure raw materials are carefully selected for casting and supplemented with electro-galvanizing surface treatment, ensuring the purity of the internal material of the product and its excellent anti-rust and anti-corrosion ability on the outside.

Customer value: The product has a longer life cycle, extremely strong wear resistance and anti-deformation ability, and can be used through multiple project turnovers without performance degradation. It significantly reduces the long-term tool amortization and maintenance costs for contractors, and has a higher return on investment.

3. Precise dimensions and stable connection performance

The root of the advantage: The liquid metal cools and solidifies in the precision mold, ensuring that the dimensions of each fixture are highly accurate and uniform. The subsequent polishing and grinding process further eliminated burrs and tolerances.

Customer value: During installation, it can perfectly fit the steel formwork, achieving a "seamless" connection, effectively preventing concrete leakage, ensuring a smooth and flat surface of the poured concrete, and enhancing the quality and aesthetic appeal of the project.

4. Wide applicability and global project verification

Advantage root: Specifically designed for steel European standard formwork systems, it is suitable for various formwork support scenarios such as floor slabs and walls.

Customer value: Its strong versatility can meet various construction needs such as residential, commercial and industrial projects. At present, our products have been stably exported to multiple markets such as Southeast Asia, the Middle East, Europe and America. They have undergone strict tests in different regions and standard projects, which has proved their outstanding universality and reliability.

5. Dual guarantees of materials and quality from industrial bases

Advantage root: Relying on the geographical advantage of Tianjin as a steel manufacturing base, we can conveniently screen high-quality steel of different grades and conduct strict quality control from the source of raw materials.

Customer value: This means that for every batch of casting fixtures we deliver, the materials are carefully selected and the production process is strictly monitored to ensure that the products you receive are 100% in line with the company's principle of "quality First".

Advantages

1.Outstanding structural integrity and load-bearing capacity

Advantage root: The integrated casting process of "heating and melting - casting and forming" is adopted, which makes the metal molecular structure more uniform and dense, with no welding points or splicing seams.

Customer value: It fundamentally eliminates the risk of cracking due to loose welding, can withstand the huge lateral pressure and static load generated during concrete pouring, and provides absolutely reliable safety guarantees for key projects such as high-rise buildings and large-scale infrastructure.

2. Extremely long service life and outstanding durability

Advantage root: High-quality pure raw materials are carefully selected for casting and supplemented with electro-galvanizing surface treatment, ensuring the purity of the internal material of the product and its excellent anti-rust and anti-corrosion ability on the outside.

Customer value: The product has a longer life cycle, extremely strong wear resistance and anti-deformation ability, and can be used through multiple project turnovers without performance degradation. It significantly reduces the long-term tool amortization and maintenance costs for contractors, and has a higher return on investment.

3. Precise dimensions and stable connection performance

The root of the advantage: The liquid metal cools and solidifies in the precision mold, ensuring that the dimensions of each fixture are highly accurate and uniform. The subsequent polishing and grinding process further eliminated burrs and tolerances.

Customer value: During installation, it can perfectly fit the steel formwork, achieving a "seamless" connection, effectively preventing concrete leakage, ensuring a smooth and flat surface of the poured concrete, and enhancing the quality and aesthetic appeal of the project.

4. Wide applicability and global project verification

Advantage root: Specifically designed for steel European standard formwork systems, it is suitable for various formwork support scenarios such as floor slabs and walls.

Customer value: Its strong versatility can meet various construction needs such as residential, commercial and industrial projects. At present, our products have been stably exported to multiple markets such as Southeast Asia, the Middle East, Europe and America. They have undergone strict tests in different regions and standard projects, which has proved their outstanding universality and reliability.

5. Dual guarantees of materials and quality from industrial bases

Advantage root: Relying on the geographical advantage of Tianjin as a steel manufacturing base, we can conveniently screen high-quality steel of different grades and conduct strict quality control from the source of raw materials.

Customer value: This means that for every batch of casting fixtures we deliver, the materials are carefully selected and the production process is strictly monitored to ensure that the products you receive are 100% in line with the company's principle of "quality First".