Light Duty Prop | Adjustable Steel Shore Post for Construction Support

Our scaffolding steel supports (also known as support columns or top supports) are a safe and efficient alternative to traditional wooden supports in modern construction. The products are mainly divided into two series: light and heavy. Both are precisely manufactured from high-quality steel pipes and feature extremely high load-bearing capacity and durability. With its original telescopic design, the length can be easily adjusted to precisely adapt to different floor heights and complex support requirements. All products undergo multiple surface treatments to ensure stability and reliability under various working conditions, providing solid and safe support for concrete pouring.

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube Dia(mm) |

Outer Tube Dia(mm) |

Thickness(mm) |

Customized |

| Heavy Duty Prop |

1.7-3.0m |

48/60/76 |

60/76/89 |

2.0-5.0 | Yes |

| 1.8-3.2m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.0-3.5m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.2-4.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 3.0-5.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| Light Duty Prop | 1.7-3.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

| 1.8-3.2m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.0-3.5m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.2-4.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

Other Information

| Name | Base Plate | Nut | Pin | Surface Treatment |

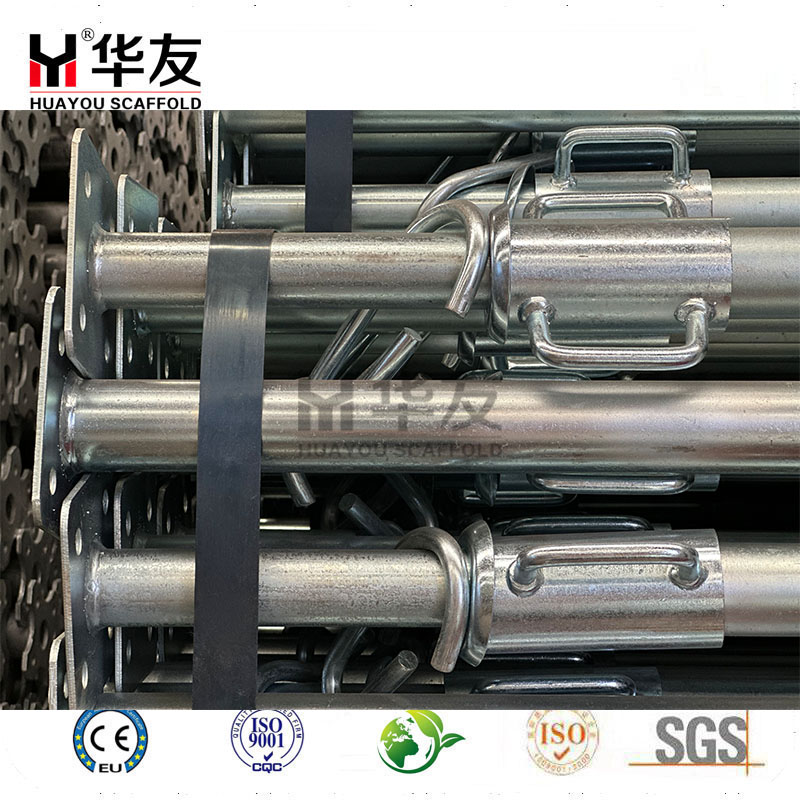

| Light Duty Prop | Flower type/Square type | Cup nut/norma nut | 12mm G pin/ Line Pin | Pre-Galv./Painted/Powder Coated |

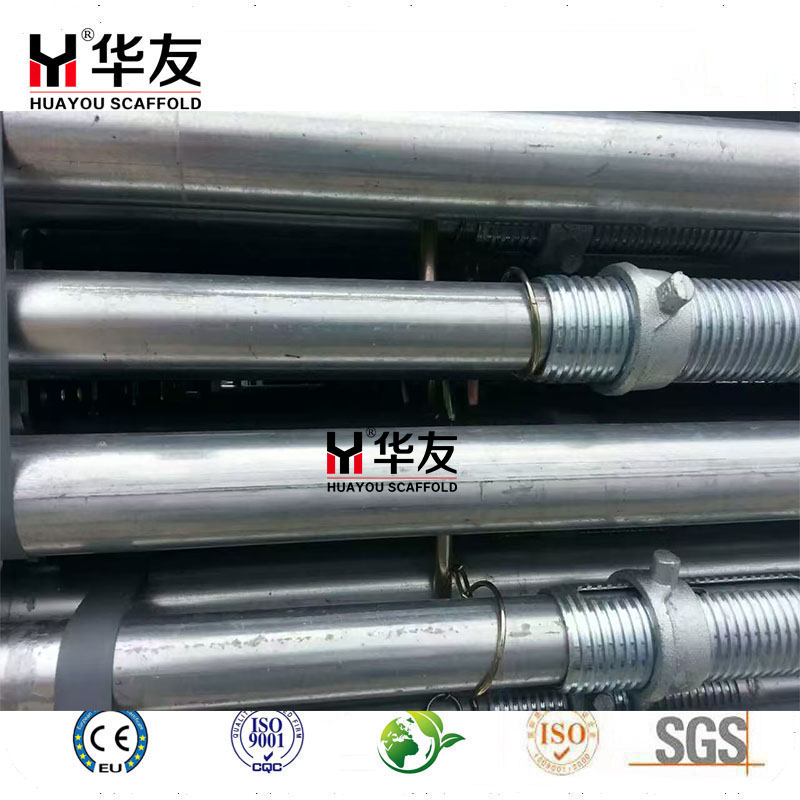

| Heavy Duty Prop | Flower type/Square type | Casting/Drop forged nut | 14mm/16mm/18mm G pin | Painted/Powder Coated/Hot Dip Galv. |

Advantages

1. Dual-series design, precisely matching load requirements

We offer two major series of supports: Light Duty and Heavy Duty, comprehensively covering different construction scenarios.

Lightweight support: It adopts smaller pipe diameters such as OD40/48mm and OD48/57mm, and is combined with a unique Cup Nut to achieve a lightweight design. The surface is available with various treatments such as painting, pre-galvanizing, and electro-galvanizing, offering both rust prevention and cost advantages, and is suitable for conventional load support.

Heavy-duty supports: Larger pipe diameters of OD48/60mm and above are adopted, with pipe wall thickness usually ≥2.0mm, and are equipped with heavy-duty nuts formed by casting or die forging. The overall structural strength and load-bearing capacity far exceed those of traditional wooden supports or lightweight supports, and are specially designed for core areas with large loads and high safety requirements.

2. Safe and efficient, it fully replaces traditional wooden supports

Compared with the traditional wooden supports that are prone to breakage and decay, our steel supports have revolutionary advantages:

Ultra-high safety: Steel structures offer a load-bearing capacity and stability far exceeding that of wood, significantly reducing construction risks.

Outstanding durability: Steel is resistant to corrosion and moisture, can be reused for many years, and has an extremely low life cycle cost.

Flexibility and adjustability: The telescopic design enables precise and rapid adjustment of the support height, adapting to different floor heights and construction requirements, significantly enhancing the efficiency of formwork erection.

3. Precision manufacturing processes ensure quality and consistency

Quality stems from strict control over details:

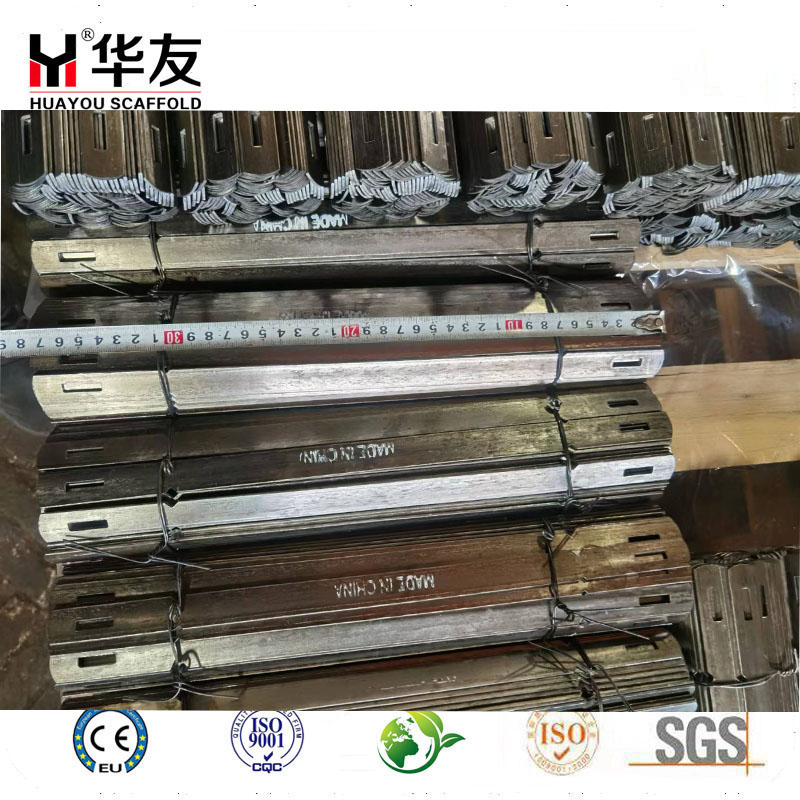

Precise hole opening: The inner tube adjustment holes are cut by laser. Compared with traditional stamping, the hole diameters are more accurate and the edges are smoother, ensuring smooth adjustment, firm locking, and no stress concentration points.

Craftsmanship: The core production team has over 15 years of professional experience, constantly optimizing the production process to ensure that every product is exquisitely crafted and reliable in performance.

4. A strict quality inspection system builds a globally trusted brand

We are well aware that supporting products is related to the safety of life and property. Therefore, we have established a quality assurance system that exceeds industry standards

Double quality inspection: Each batch of raw materials is strictly inspected by the internal QC department. The finished products are tested in accordance with customer requirements and international quality standards to ensure absolute safety.

Internationally common: The product complies with multiple international construction safety standards and sells well worldwide under names such as "Acrow Jack" and "Steel Struts", and is deeply trusted by customers in Southeast Asia, the Middle East, Europe, America and other regions.

5. One-stop solutions and outstanding services

As a professional manufacturer of scaffolding and support systems, we not only offer individual products, but also provide safe and economical overall support solutions based on your project drawings and specific requirements. Adhering to the principle of "Quality First, Customer Supreme, Service Ultimate", we are committed to becoming your most reliable and professional partner.

Basic information

As a professional manufacturer, Huayou strictly selects high-quality steel materials such as Q235, S355, and EN39, and through precise cutting, welding, and multiple surface treatment processes, ensures that each supporting product has outstanding strength and durability. We offer a variety of treatment methods such as hot-dip galvanizing and spraying, and package them in bundles or pallets. With flexible and efficient delivery services (20-30 days for regular orders), we meet the dual demands of global customers for quality and timeliness.

FAQS

1. What is Scaffolding Steel Prop? What are its common names?

Scaffolding steel supports are adjustable temporary support components used for concrete formwork, beams and floor slab structures. It is also known as Shoring Prop (support column), Telescopic Prop (Telescopic support), Adjustable Steel Prop (adjustable Steel support), and is called Acrow Jack or Steel Struts in some markets. Compared with traditional wooden supports, it has higher safety, load-bearing capacity and durability.

2. What are the differences between Light Duty Prop and Heavy Duty Prop?

The main differences between the two lie in the size, thickness of the steel pipe and the structure of the nut:

Lightweight support: Smaller diameter steel pipes (such as outer diameters OD40/48mm, OD48/57mm) are adopted, and Cup nuts (Cup Nut) are used. They are relatively light in weight and the surface can be treated with painting, pre-galvanizing or electro-galvanizing.

Heavy-duty support: Larger and thicker steel pipes (such as OD48/60mm, OD60/76mm, OD76/89mm, thickness ≥2.0mm) are adopted, and the nuts are castings or forgings, with stronger load-bearing capacity, suitable for high-load working conditions.

3. What advantages do steel supports have over traditional wooden supports?

Steel supports have significant advantages:

Higher safety: The strength of steel is much higher than that of wood, and it is less likely to break or rot.

Stronger load-bearing capacity: Can withstand greater loads;

Adjustable height: Adapt to different construction height requirements through an extendable structure;

Longer service life: Durable and reusable, reducing long-term costs.

4. How do you ensure the product quality of steel supports?

We strictly control quality through multiple links:

Material inspection: Each batch of raw materials is inspected by the quality inspection department.

Process accuracy: The inner tube is punched by laser (not by stamping) to ensure precise hole positions and stable structure.

Experience and Technology: Our production team has over 15 years of experience and continuously optimizes the process flow.

The standard complies with: The product can pass relevant quality tests as per customer requirements and has been widely recognized by the market.

5. In which construction scenarios are steel supports mainly applied?

Steel supports are mainly used in the temporary support systems of concrete structure construction. Typical applications include:

Formwork support for concrete pouring of floor slabs, beams, walls, etc.

Temporary support for Bridges, factories and other facilities that require large spans or high loads;

Any occasion that requires adjustable, high-load-bearing and safe and reliable support