Light Duty Scaffolding steel prop

Scaffolding steel prop mainly use for formwork, Beam and some other plywood to support concrete structure. Earlier years ago, all construction contractor use wood pole that is very eary to be broken and rotten when pour concrete. That means, steel prop is more safe, more loading capacity, more durable, also can adjustable different length for different height.

Steel Prop have many different names, for example, Scaffolding prop, shoring, telescopic prop, adjustable steel prop, Acrow jack, steel structs etc

Mature Production

You can find the best quality prop from Huayou, our every batch materials of prop will be inspected by our QC department and also tested according the quality standard and requirements by our customers.

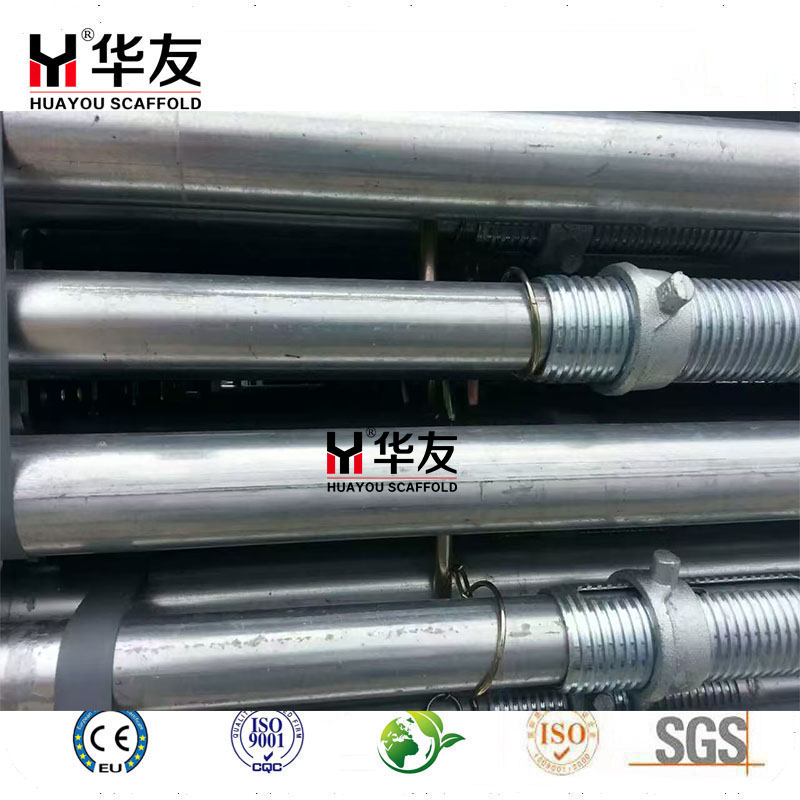

The inner pipe is punched holes by laser machine instead of load machine that will be more accurate and our workers are experienced for 15years and improve the production processing technology time and time again. All our efforts in production of scaffolding make our products gained great reputation among our clients.

Features

1.Simple and flexible

2.Easier assembling

3.High load capacity

Basic information

1.Brand: Huayou

2.Materials: Q235, Q195, Q355 , S235, S355, EN39 pipe

3.Surface treatment: hot dipped galvanized , electro-galvanized, pre-galvanized, painted, powder coated.

4.Production procedure: material---cut by size---punching hole---welding ---surface treatment

5.Package: by bundle with steel strip or by pallet

6.MOQ: 500 pcs

7.Delivery time: 20-30days depends on the quantity

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube Dia(mm) |

Outer Tube Dia(mm) |

Thickness(mm) |

Customized |

| Heavy Duty Prop |

1.7-3.0m |

48/60/76 |

60/76/89 |

2.0-5.0 | Yes |

| 1.8-3.2m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.0-3.5m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.2-4.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 3.0-5.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| Light Duty Prop | 1.7-3.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

| 1.8-3.2m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.0-3.5m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.2-4.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

Other Information

| Name | Base Plate | Nut | Pin | Surface Treatment |

| Light Duty Prop | Flower type/Square type | Cup nut/norma nut | 12mm G pin/ Line Pin | Pre-Galv./Painted/

Powder Coated |

| Heavy Duty Prop | Flower type/Square type | Casting/Drop forged nut | 14mm/16mm/18mm G pin | Painted/Powder Coated/

Hot Dip Galv. |

Welding Technician Requirements

For all our heavy duty prop, we have own Quality requirements.

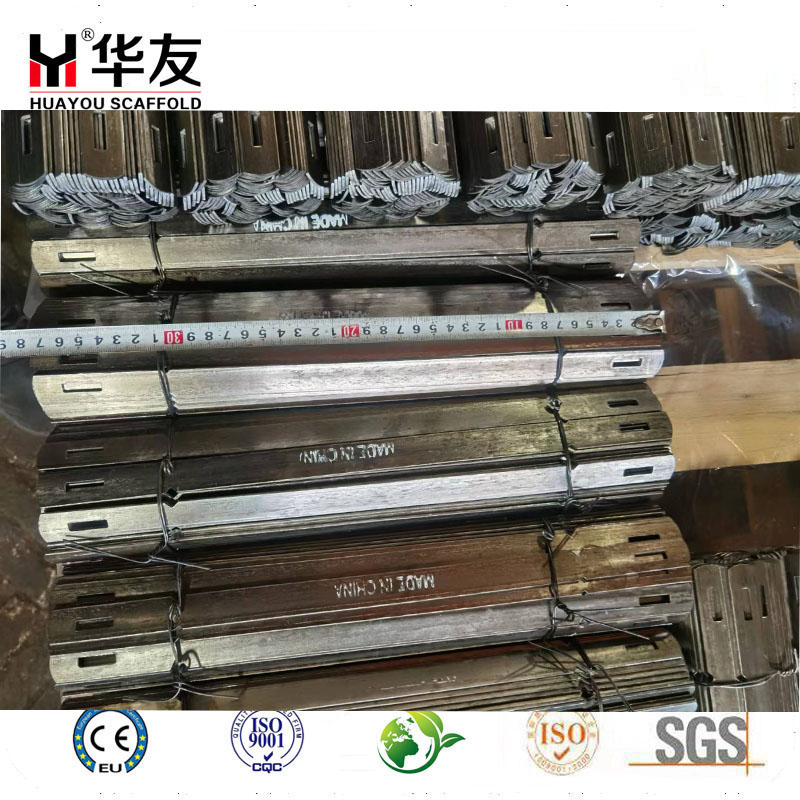

Raw materials steel grade testing, Diameter, thickness mesasure, then cutting by laser machine that control 0.5mm tolerance.

And welding depth and width must meet our factory standard. all welding must keep same level and same speed to ensure no faulty weld and false weld. All welding is guaranteed to be free of spatter and residue

Please check the follow welding showing.

Details Showing

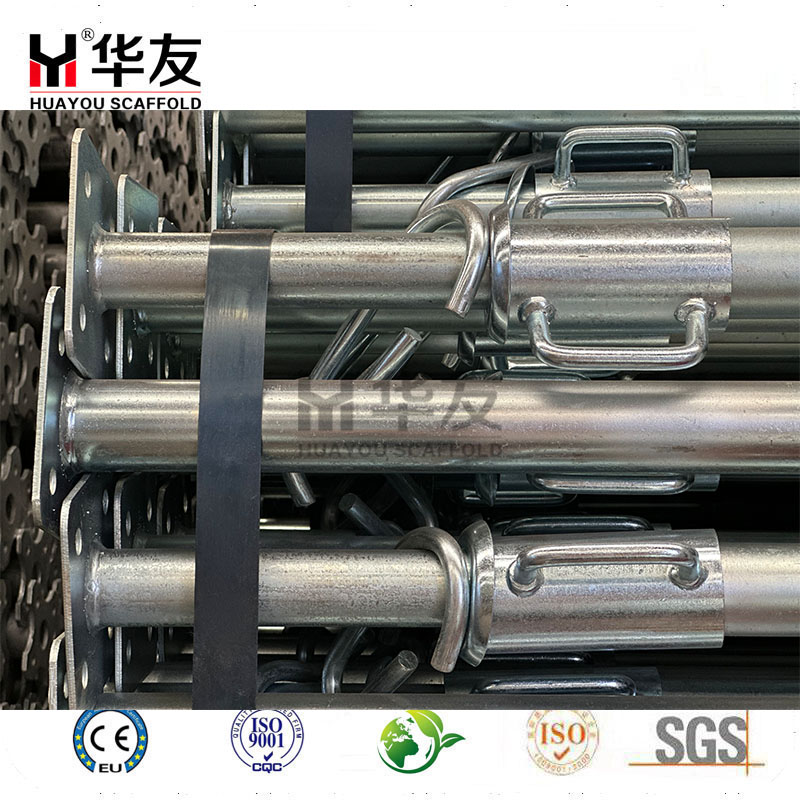

Quality controlling is very important for our production. Please check the follow pictures that just part of our light duty props.

Until now, almost all props type can be produced by our advanced machines and mature workers. You just can show your drawing details and pictures. we can produce for you 100% same with cheap price.

Testing Report

Our team will make testing before shipment base on customers' requirements.

Now, there are two types for testing.

One is our factory make loading testing by hydraulic press.

The other is send our samples to SGS lab.