Multifunctional Telescopic Steel Props For Strong Support Of Formwork

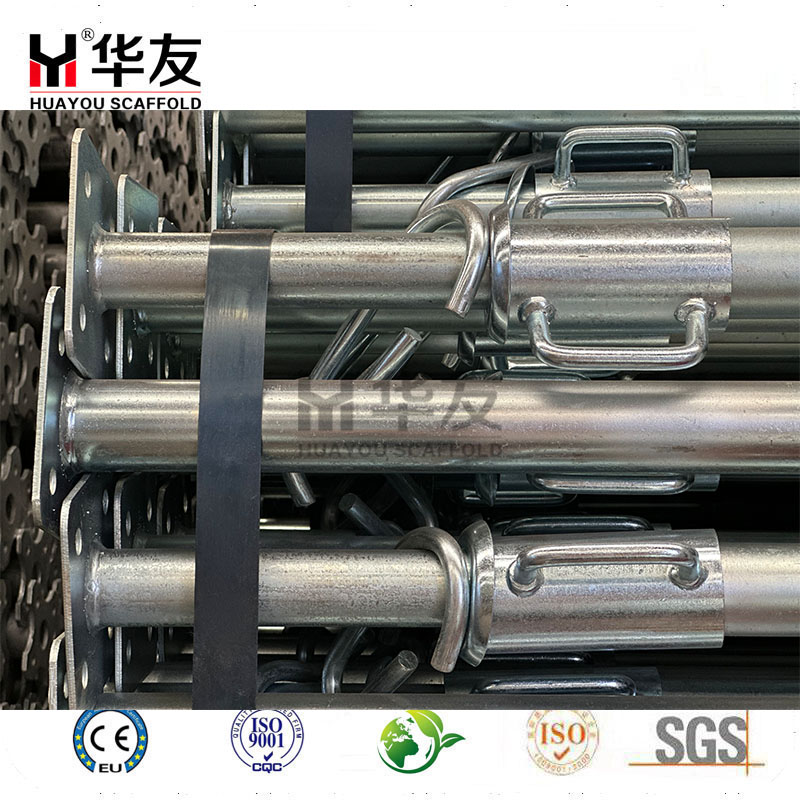

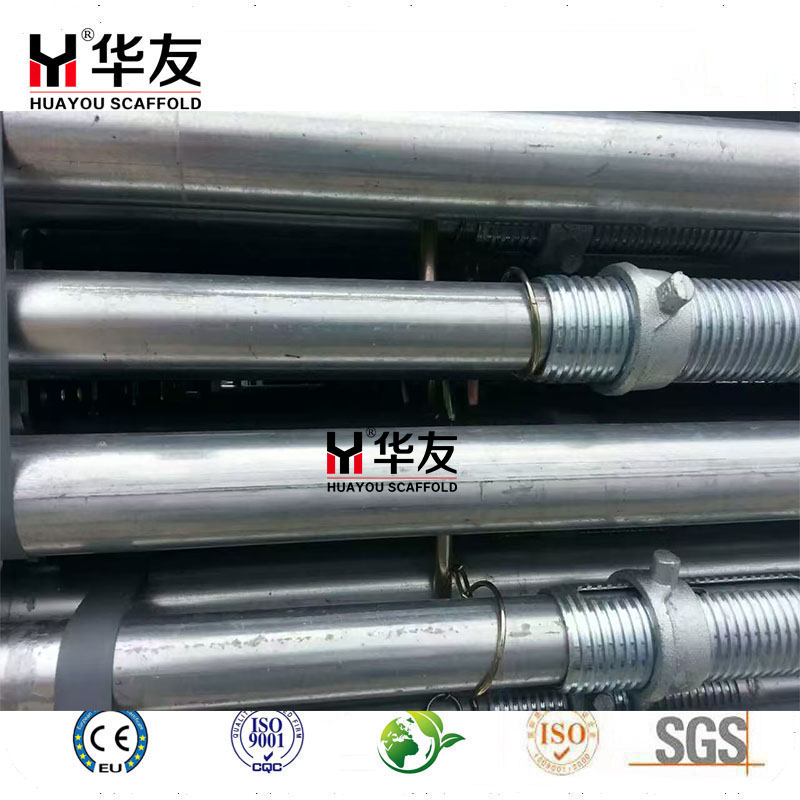

Scaffolding steel pillars are load-bearing components that provide core support for formwork, beams and concrete structures. The products are divided into two major series: light and heavy, which are respectively made of steel pipes of different specifications and thicknesses, and have excellent load-bearing performance. The pillar can be flexibly adjusted in height through precisely machined cast steel or forged nuts, meeting the needs of various construction scenarios. Compared with traditional wooden supports, it has a solid structure, strong load-bearing capacity, and significantly improved safety and durability. This adjustable steel prop (also known as Acrow jack or shoring) is an ideal support solution that is safe, efficient and reusable in modern construction.

Specification Details

|

Item |

Min Length-Max. Length |

Inner Tube Dia(mm) |

Outer Tube Dia(mm) |

Thickness(mm) |

Customized |

| Heavy Duty Prop |

1.7-3.0m |

48/60/76 |

60/76/89 |

2.0-5.0 | Yes |

| 1.8-3.2m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.0-3.5m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 2.2-4.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| 3.0-5.0m | 48/60/76 | 60/76/89 | 2.0-5.0 | Yes | |

| Light Duty Prop | 1.7-3.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

| 1.8-3.2m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.0-3.5m | 40/48 | 48/56 | 1.3-1.8 | Yes | |

| 2.2-4.0m | 40/48 | 48/56 | 1.3-1.8 | Yes |

Other Information

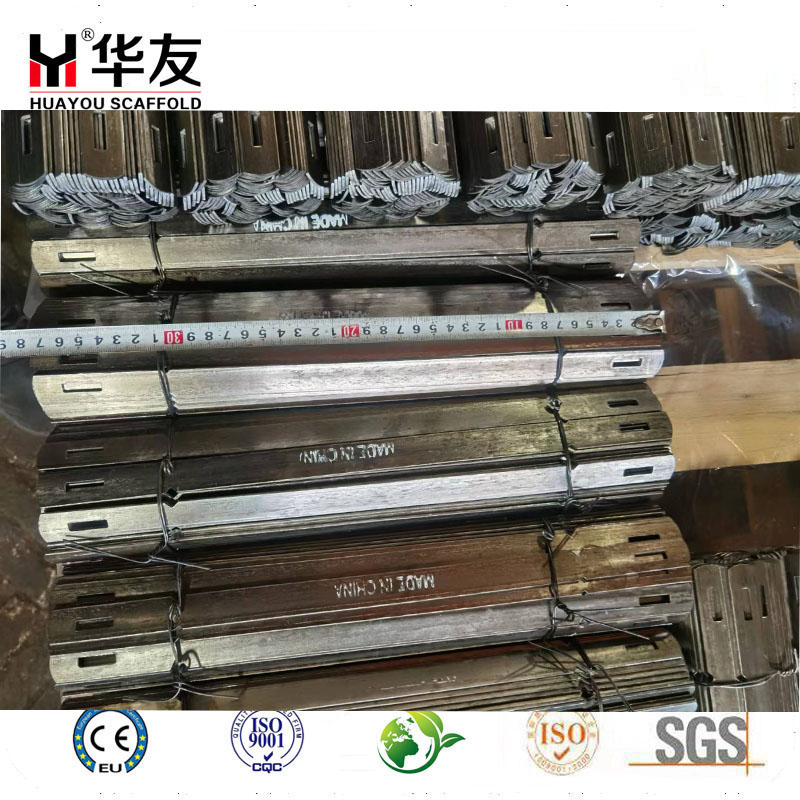

| Name | Base Plate | Nut | Pin | Surface Treatment |

| Light Duty Prop | Flower type/Square type | Cup nut/norma nut | 12mm G pin/ Line Pin | Pre-Galv./Painted/

Powder Coated |

| Heavy Duty Prop | Flower type/Square type | Casting/Drop forged nut | 14mm/16mm/18mm G pin | Painted/Powder Coated/

Hot Dip Galv. |

Advantages

1. Scientific classification and precise load-bearing

The product line covers two major series: lightweight and heavy-duty. The lightweight pillar is designed with small-diameter pipes such as OD40/48mm and cup-shaped nuts, making the overall weight very light. The heavy-duty pillars are made of large-diameter, thick-walled (≥2.0mm) steel pipes of OD60mm or more, and are equipped with cast or forged heavy-duty nuts. They are specially designed to cope with extreme load conditions and meet diverse demands ranging from conventional to high load-bearing capacity.

2. Structurally safe, stable and durable

The all-steel structure fundamentally overcomes the defects of wooden pillars such as easy breakage and decay, and has higher load-bearing strength and structural stability. The telescopic and adjustable design can flexibly adapt to different construction heights, ensuring that the support system is always in the best working condition and greatly enhancing the safety and reliability of the construction site.

3. Flexible adjustment and wide application

The pillar adopts a telescopic structure, with its height adjustable flexibly. It can quickly adapt to different floor heights and construction requirements, providing precise and reliable temporary support for formwork, beams and concrete structures. Its application scenarios are extremely wide.

4. Economic maintenance and long-lasting anti-corrosion

We offer a variety of surface treatment solutions including pre-galvanizing, electro-galvanizing and painting, which effectively resist corrosion, significantly extend the service life of products, reduce long-term maintenance costs and replacement frequency, and have excellent full life cycle economy.

5. It has strong versatility and is widely recognized

This product has various common names in the industry, such as adjustable steel pillar, telescopic support, Acrow jack, etc., which reflect its mature design and wide international recognition, making it convenient for global customers to purchase and apply.

FAQS

1.Q: What is scaffolding steel support? What are its main uses?

A: Scaffolding steel support (also known as top support, support column or Acrow Jack) is a kind of adjustable length telescopic (telescopic) steel pipe pillar. It is mainly used in formwork engineering for buildings, providing vertical support for concrete structures such as beams and slabs, replacing traditional wooden pillars that are prone to decay and breakage. It has higher safety, load-bearing capacity and durability.

2. Q: What types of steel supports does your company mainly provide?

A: We mainly offer two types of steel supports

Light Duty Prop: Manufactured with smaller pipe diameters (such as OD40/48mm, OD48/57mm), it is lightweight. Its feature is that it is adjusted using a Cup Nut. Surface treatment is usually painting, pre-galvanizing or electro-galvanizing.

Heavy Duty Prop: It is made of steel pipes with larger pipe diameters and thicker wall thicknesses (such as OD48/60mm, OD60/76mm, OD76/89mm, and the thickness is usually ≥2.0mm). Its nuts are cast or forged, which makes the structure more solid and has a stronger load-bearing capacity.

3. Q: What are the advantages of steel supports over traditional wooden supports?

A: Compared with traditional wooden supports, our steel supports have three core advantages:

Safer: Steel has high strength, is not prone to breakage, and has a large load-bearing capacity.

More durable: Not prone to rot, reusable many times, and with a long service life.

More flexible: The length is adjustable and can easily adapt to different construction height requirements.

4. Q: What are the surface treatment methods for steel supports? How to choose?

A: We offer a variety of surface treatment methods to adapt to different usage environments and budgets

Painting: Economical and cost-effective, providing basic rust protection.

Electro-galvanized: It has better rust prevention than painting and is suitable for indoor or dry environments.

Pre-galvanized & hot-dip galvanized: Offers outstanding anti-corrosion performance, especially suitable for outdoor, humid or corrosive environments, with the longest service life.

5. Q: What are the differences between the "nuts" of steel supports?

A: Nuts are the key components that distinguish support types and load-bearing capacities.

The lightweight support adopts Cup nuts, which are light in weight and easy to adjust.

Heavy-duty supports use Casting or Drop Forged nuts, which are larger in volume, heavier in weight, and have extremely high strength and durability, sufficient to handle heavy-load conditions.