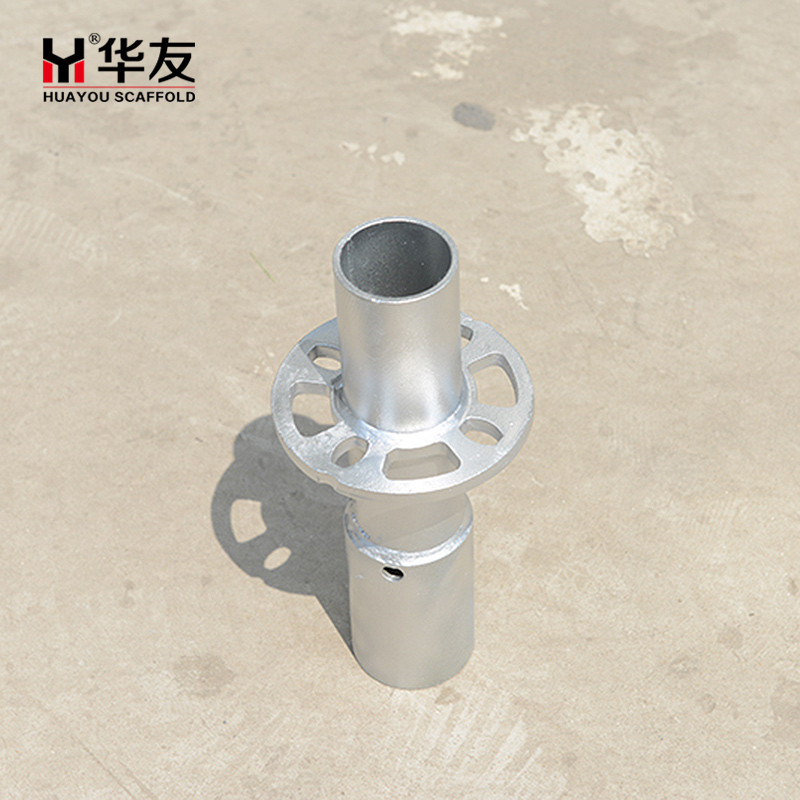

Professional Ringlock System Scaffolding – Robust Design & Quick Erection

Ringlock Ledger serves as the essential horizontal connector that securely links vertical standards, forming the fundamental framework of the system. Manufactured with precision, each ledger is constructed using high-strength OD48mm steel pipes and fitted with durable cast ledger heads, available in both wax and sand mould types to suit varied specifications. While not the primary load-bearing component, this indispensable element ensures structural integrity and modular flexibility, with standard and customized lengths available to meet project-specific requirements.

Size as following

|

Item |

OD (mm) |

Length (m) |

THK (mm) |

Raw Materials |

Customized |

|

Ringlock Single Ledger O |

42mm/48.3mm |

0.3m/0.6m/0.9m/1.2m/1.5m/1.8m/2.4m |

1.8mm/2.0mm/2.5mm/2.75mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

42mm/48.3mm |

0.65m/0.914m/1.219m/1.524m/1.829m/2.44m |

2.5mm/2.75mm/3.0mm/3.25mm | STK400/S235/Q235/Q355/STK500 | YES | |

|

48.3mm |

0.39m/0.73m/1.09m/1.4m/1.57m/2.07m/2.57m/3.07m/4.14m |

2.5mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

|

Size can be customerized |

|||||

Advantages

1.Outstanding safety and structural stability

Triangular stable structure: The horizontal crossbar (Ledger) and the vertical diagonal brace are self-lockingly connected through wedge pins and the hub (Rosette), forming a stable triangular mechanical unit. It effectively resists deformation forces in both horizontal and vertical directions, ensuring that the entire support system is as solid as a rock.

Overall system safety: From standard upright poles, horizontal bars to scaffolding boards and ladders, all components together form a complete force-bearing and safety system. The special scaffolding boards with hooks further enhance the stability of the platform and the safety of workers' operations.

Reliable connection method: The cast steel connectors at both ends of the crossbar are mechanically self-locked with the hub through wedge pins. The connection is firm and easy to disassemble, fundamentally ensuring the strength of the node.

2. High degree of modularity and versatility

Standard module design: Adopting a uniform 500mm/600mm hub spacing, all standard components (vertical rods, horizontal rods, diagonal braces, triangular supports) are designed based on this modulus, enabling highly modular and rapid assembly.

Widely applicable scenarios: A single system can meet various engineering requirements, including bridge support, exterior wall scaffolding, stage frame, lighting tower, bridge pier construction and safety ladders, etc. This significantly enhances the versatility and utilization rate of the equipment.

3. Ultimate durability and low maintenance cost

Long-lasting anti-corrosion treatment: All steel components are treated with hot-dip galvanizing, ensuring a uniform and firm coating that never peels off and possesses extremely strong corrosion resistance.

Extremely long service life: The hot-dip galvanizing process can significantly extend the service life of steel pipes by 15 to 20 years, greatly reducing the maintenance, replacement and depreciation costs during long-term use.

4. High efficiency in economy and construction convenience

Savings in steel usage and costs: The system structure is scientifically and simply designed. Under the condition of maintaining the same load-bearing capacity, the amount of steel used is reduced, directly saving the material procurement costs for customers.

Installation and disassembly efficiency is extremely high: The simple wedge pin locking structure eliminates the need for special tools or complex skills, enabling the setup and dismantling processes to be extremely fast, significantly reducing labor costs and time costs.

Supports deep customization: The length of the crossbars (various specifications ranging from 0.39m to 3.07m) and the type of joints (such as wax molds, sand molds, etc., with different processes and weights) can all be customized according to the customer's drawings and specific engineering requirements, providing maximum flexibility.

5. Essential Core Components of the System

The crucial role of the horizontal crossbar (Ledger): As the core horizontal component connecting two upright rods, the crossbar is an indispensable part in forming the grid structure of the scaffold, transmitting loads and ensuring the overall rigidity. Although it is not the main load-bearing component, it is an absolute necessity for ensuring the integrity of the system structure and its safe operation.

Basic information

1.Brand: Huayou

2.Materials: Q355 pipe, Q235 pipe, S235 pipe

3.Surface treatment: hot dipped galvanized (mostly), electro-galvanized, powder coated, painted

4.Production procedure: material---cut by size---welding---surface treatment

5.Package: by bundle with steel strip or by pallet

6.MOQ: 1Ton

7.Delivery time: 20-30days depends on the quantity