Protect Your Space With An Octagonal Lock System

Product description

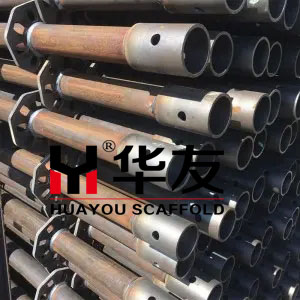

The octagonal lock type scaffolding system is a highly efficient and stable disk buckle frame, featuring a unique octagonal welded disk design. It has strong compatibility and combines the advantages of both the ring lock type and the European-style frame. We specialize in manufacturing complete sets of components, including standard vertical rods, horizontal rods, diagonal braces, bases/U-head jacks, octagonal plates, etc. We also offer various surface treatments such as painting and galvanizing, among which hot-dip galvanizing has the best anti-corrosion performance.

The product specifications are complete (such as vertical rods 48.3×3.2mm, diagonal braces 33.5×2.3mm, etc.), and custom lengths are supported. With high cost performance, strict quality inspection and professional services at its core, it ensures safety and durability, meeting all kinds of construction needs. The monthly production capacity reaches 60 containers, mainly sold in the Vietnamese and European markets.

Octagonlock Standard

The octagonal lock scaffold adopts a modular design. Its core supporting component - the octagonal lock vertical pole (standard section) is made of high-strength Q355 steel pipe (Φ48.3mm, wall thickness 3.25mm/2.5mm), and 8mm/10mm thick Q235 steel octagonal plates are welded at intervals of 500mm to ensure excellent load-bearing performance.

Unlike traditional ring lock frames, this system innovatively adopts an integral sleeve connection - each end of the vertical pole is pre-welded with a 60×4.5×90mm sleeve joint, achieving rapid and precise docking, significantly enhancing the assembly efficiency and structural stability, and outperforming the common pin-type connection method.

|

No. |

Item |

Length(mm) |

OD(mm) |

Thickness(mm) |

Materials |

|

1 |

Standard/Vertical 0.5m |

500 |

48.3 |

2.5/3.25 |

Q355 |

|

2 |

Standard/Vertical 1.0m |

1000 |

48.3 |

2.5/3.25 |

Q355 |

|

3 |

Standard/Vertical 1.5m |

1500 |

48.3 |

2.5/3.25 |

Q355 |

|

4 |

Standard/Vertical 2.0m |

2000 |

48.3 |

2.5/3.25 |

Q355 |

|

5 |

Standard/Vertical 2.5m |

2500 |

48.3 |

2.5/3.25 |

Q355 |

|

6 |

Standard/Vertical 3.0m |

3000 |

48.3 |

2.5/3.25 |

Q355 |

Advantages

1. High-strength modular design

The Q355 high-strength steel uprights (Φ48.3mm, wall thickness 3.25mm/2.5mm) are welded with 8-10mm thick octagonal plates, featuring excellent load-bearing capacity. The pre-welded sleeve joint design is more stable than the traditional pin connection, and the installation efficiency is increased by more than 50%.

2. Flexible configuration & cost optimization

Crossbars and diagonal braces are available in multiple specifications (Φ42-48.3mm, wall thickness 2.0-2.5mm)Supports custom lengths of 0.3m/0.5m multiples, suitable for various construction scenarios, to meet different load-bearing and budget requirements.

3. Super durability

We offer surface treatments such as hot-dip galvanizing (recommended), electro-galvanizing, and painting. The anti-corrosion life of hot-dip galvanizing is over 20 years, making it suitable for harsh environments.