Reliable octagonal lock scaffolding: improve your work site safety

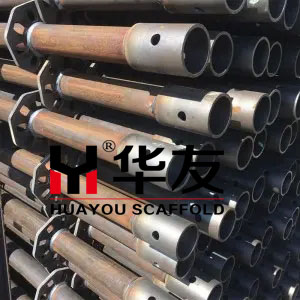

Product description

The octagonal lock bracket system, marked by its unique octagonal standard rod and disc welded structure, combines the stability of the ring lock system with the flexibility of the disc buckle system. We offer a complete set of components including standard parts, diagonal braces, bases and U-head jacks, with a full range of specifications (for example, the thickness of the vertical rods can be selected as 2.5mm or 3.2mm), and high-durability surface treatments such as hot-dip galvanizing can be carried out according to requirements.

With professional factories and large-scale production (with a monthly capacity of up to 60 containers), we not only ensure highly competitive prices and strict quality control, but our products have also successfully served multiple markets such as Vietnam and Europe. From production to packaging, we are committed to providing you with professional scaffolding solutions that are cost-effective, safe and reliable.

Octagonlock Standard

|

No. |

Item |

Length(mm) |

OD(mm) |

Thickness(mm) |

Materials |

|

1 |

Standard/Vertical 0.5m |

500 |

48.3 |

2.5/3.25 |

Q355 |

|

2 |

Standard/Vertical 1.0m |

1000 |

48.3 |

2.5/3.25 |

Q355 |

|

3 |

Standard/Vertical 1.5m |

1500 |

48.3 |

2.5/3.25 |

Q355 |

|

4 |

Standard/Vertical 2.0m |

2000 |

48.3 |

2.5/3.25 |

Q355 |

|

5 |

Standard/Vertical 2.5m |

2500 |

48.3 |

2.5/3.25 |

Q355 |

|

6 |

Standard/Vertical 3.0m |

3000 |

48.3 |

2.5/3.25 |

Q355 |

Octagonlock Ledger

|

No. |

Item |

Length (mm) |

OD(mm) |

Thickness (mm) |

Materials |

|

1 |

Ledger/Horizontal 0.6m |

600 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

|

2 |

Ledger/Horizontal 0.9m |

900 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

|

3 |

Ledger/Horizontal 1.2m |

1200 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

|

4 |

Ledger/Horizontal 1.5m |

1500 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

|

5 |

Ledger/Horizontal 1.8m |

1800 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

|

6 |

Ledger/Horizontal 2.0m |

2000 |

42/48.3 |

2.0/2.3/2.5 |

Q235 |

Octagonlock Diagonal Brace

|

No. |

Item |

Size(mm) |

W(mm) |

H(mm) |

|

1 |

Diagonal Brace |

33.5*2.3*1606mm |

600 |

1500 |

|

2 |

Diagonal Brace |

33.5*2.3*1710mm |

900 |

1500 |

|

3 |

Diagonal Brace |

33.5*2.3*1859mm |

1200 |

1500 |

|

4 |

Diagonal Brace |

33.5*2.3*2042mm |

1500 |

1500 |

|

5 |

Diagonal Brace |

33.5*2.3*2251mm |

1800 |

1500 |

|

6 |

Diagonal Brace |

33.5*2.3*2411mm |

2000 |

1500 |

Advantages

1. Stable structure and strong versatility

Innovative octagonal design: The unique octagonal vertical rod and disc welding structure provide stronger torsional rigidity and more stable connection points compared to traditional circular rods, ensuring outstanding overall system stability.

Wide compatibility: The system design is in line with the ring lock and disk buckle type scaffolding, with high component universality, easy to operate, and can adapt to various complex construction scenarios.

2. All-round production and customization capabilities

All components are available: We can not only produce all core components (such as standard parts, diagonal braces, bases, etc.), but also provide various accessories (such as octagonal plates, wedge pins), ensuring that you can get a complete solution.

Flexible and diverse specifications: We offer a variety of pipe thicknesses and standard lengths, and also accept customization to ensure that the products perfectly match your specific project requirements.

3. Outstanding quality and long-lasting durability

Diversified high-end surface treatments: Offering spray painting, powder coating, electro-galvanizing and top-grade hot-dip galvanizing treatments. Among them, hot-dip galvanized components have unparalleled corrosion resistance and an extremely long service life, especially suitable for harsh construction environments.

Strict quality control: From raw materials to finished products, a strict quality control system is implemented to ensure the dimensional accuracy and structural strength of each component.

4. Professional services and a strong supply chain

The professionalism of market validation: The products are mainly exported to the demanding markets of Vietnam and Europe, and their quality and standards have been internationally recognized.

Strong production capacity guarantee: With a monthly production capacity of up to 60 containers, it has the ability to undertake large-scale project orders and ensure stable and timely delivery.

Professional export packaging: We adopt expert-level packaging solutions to ensure that your goods remain intact and arrive safely at your construction site during long-distance transportation.

5. Extremely high comprehensive cost performance

While offering all the above advantages, we insist on providing the most competitive prices in the market to ensure that you can obtain the highest value scaffolding solution at the best cost.