Scaffolding Ledger Head Provides Efficient Construction

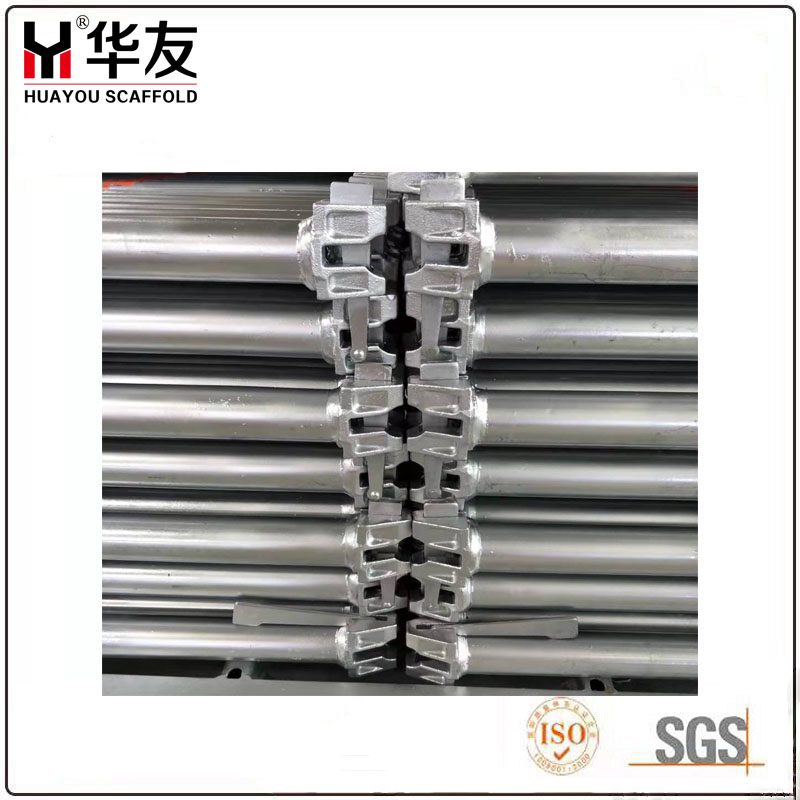

The scaffolding beam head, also known as the beam end, is a critical component of any scaffolding build. It is expertly welded and connected to the beam and uses wedge pins to connect with standard parts, providing a reliable, secure connection. Made from high-quality cast iron, our beam heads are able to withstand the rigors of the construction environment, ensuring long-term durability.

We offer two different types of scaffolding ledger head, based on the manufacturing process: pre-sanded and wax-finished. The pre-sanded surface offers excellent corrosion and abrasion resistance, making it ideal for projects that are exposed to the elements outdoors. The wax-finished surface, on the other hand, offers a smooth appearance while maintaining the strength and reliability you expect from our products. Whichever you choose, we can ensure that your beam heads will meet the needs of your construction project.

Our scaffolding fixing heads are more than just a product, they are a solution designed to simplify the construction process. Integrating our fixing heads into your scaffolding system can enhance stability and safety on site, ultimately increasing productivity. Our fixing heads are easy to install and compatible with a variety of scaffolding systems, making them the first choice of construction professionals.

Product Advantage

One of the main advantages of the scaffolding beam head is its sturdy construction. Made of cast iron, it ensures durability and resistance to wear, making it suitable for heavy-duty applications.

In addition, it is designed to be easy to assemble and disassemble, which is essential for increasing efficiency on the construction site. The wedge pin connection ensures a secure fit, minimizing the risk of structural damage during use.

In addition, our company was founded in 2019 and has successfully expanded its market to serve nearly 50 countries around the world. This growth has enabled us to establish a sound procurement system, ensuring that we can meet the diverse needs of our customers with high-quality scaffolding products, including beam heads.

Product shortcoming

Cast iron components can easily lead to problems such as rust and corrosion if not properly maintained, especially in adverse weather conditions.

In addition, the weight of cast iron components can make shipping and handling more difficult, which can increase labor costs.

Main Application

In the construction industry, safety and efficiency are of vital importance. The scaffolding beam head is one of the key components to ensure safety and efficiency. It is usually called the beam end, which is welded on the beam and connected with the standard parts by wedge pins to ensure the safety and stability of the scaffolding system frame.

Base plate heads are mainly made of cast iron, which is known for its durability and strength. According to the production process, base plate heads can be divided into two types: coated sand and wax polished. The choice of these two types usually depends on the specific requirements of the construction project, including environmental conditions and load-bearing requirements.

More than just a component, a scaffolding beam is the cornerstone of safe construction. By understanding its function and the materials used in its production, construction professionals can make informed decisions that improve the safety and efficiency of their projects. As we continue to grow and innovate, we remain committed to providing best-in-class scaffolding solutions to meet the changing needs of the industry. Whether you are a contractor, builder or supplier, investing in quality scaffolding components like beams is essential to the success of your project.

FAQS

Q1:What materials are used for account book headings?

Scaffolding joints are mainly made of cast iron, which can provide the durability and strength required for scaffolding applications. According to the production process, scaffolding joints can be divided into two types: coated sand type and wax polished type. The choice of these two types usually depends on the specific requirements and environmental conditions of the project.

Q2:How do beam heads ensure scaffolding safety?

Beam headers play a vital role in maintaining the structural integrity of a scaffolding system. By securely attaching the beams to the scaffolding members, it helps to evenly distribute the load and prevent any potential collapse. Therefore, choosing high-quality beam headers is crucial for any construction project.

Q3:Why choose our account book?

Since establishing our export company in 2019, our business scope has expanded to nearly 50 countries around the world. Our commitment to quality and safety has enabled us to establish a sound procurement system to ensure that our customers receive the highest quality products. Our book heads are crafted from high-quality cast iron and are available in both pre-sanded and wax-polished finishes, designed to meet the highest industry standards.