Scaffolding Prop Fork Head

| Name | Pipe Dia mm | Fork size mm | Surface Treatment | Raw materials | Customized |

| Fork Head | 38mm | 30x30x3x190mm, 145x235x6mm | Hot Dip Galv/Electro-Galv. | Q235 | Yes |

| For Head | 32mm | 30x30x3x190mm, 145x230x5mm | Black/Hot Dip Galv/Electro-Galv. | Q235/#45 steel | Yes |

Features

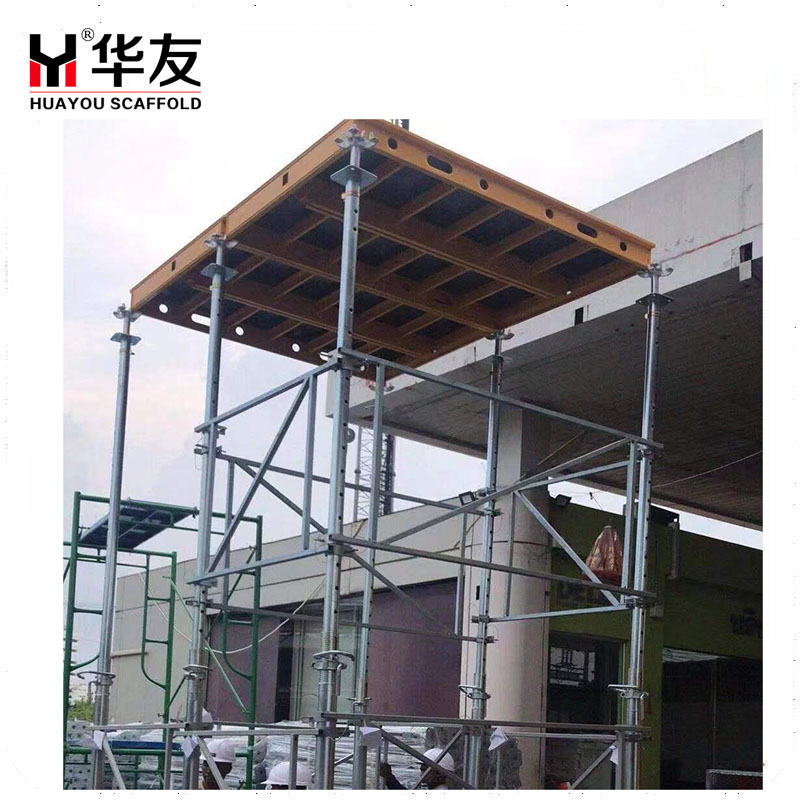

1.Simple

2.Easier assembling

3.High load capacity

Basic information

1.Brand: Huayou

2.Materials: Q235, Q195, Q355

3.Surface treatment: hot dipped galvanized , electro-galvanized

4.Production procedure: material---cut by size---punching hole---welding ---surface treatment

5.Package: by bundle with steel strip or by pallet

6.MOQ: 500 pcs

7.Delivery time: 20-30days depends on the quantity

Welding Technician Requirements

For all our Fork Head, we have own Quality requirements.

Raw materials steel grade testing, Diameter, thickness mesasure, then cutting by laser machine that control 0.5mm tolerance.

And welding depth and width must meet our factory standard. all welding must keep same level and same speed to ensure no faulty weld and false weld. All welding is guaranteed to be free of spatter and residue

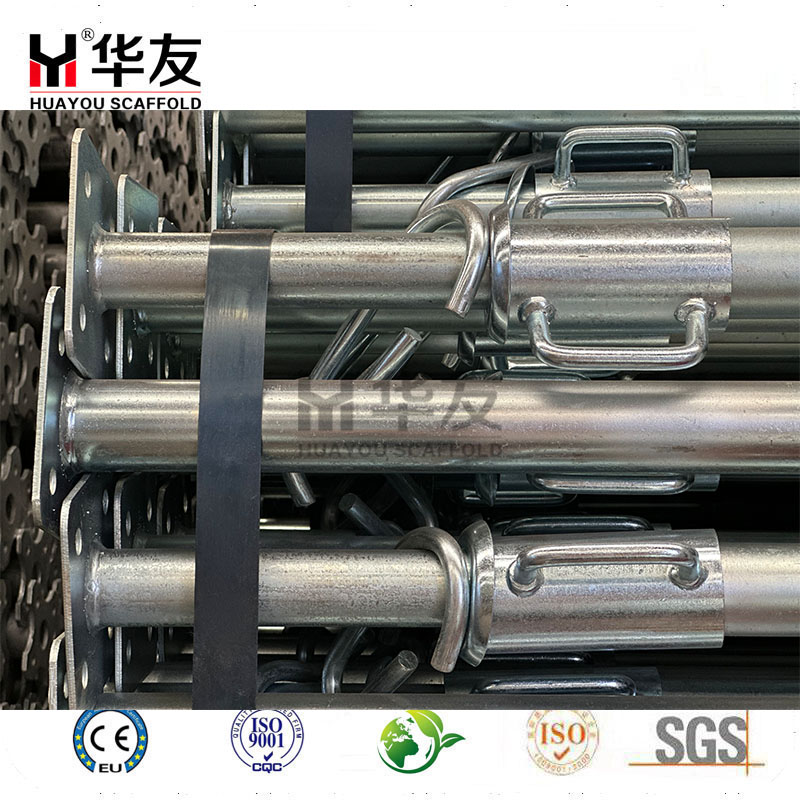

Please check the follow welding showing.

Packing and Loading

The Fork Head mainly sell to European and American markets. Most our customers also buy formwork together. They have very high requirements for packing and loading.

Normally, we packed them with steel pallet or some less use wood pallet Base on customers demand.

We guarantee all goods that qualified to load containers.