Scaffolding Timber Improves Construction Safety

Company Introduction

Since our establishment in 2019, we have been committed to expanding into the global market. With our perfect procurement system to ensure quality and efficiency, our export company has successfully served customers in nearly 50 countries. We understand the diverse needs of our customers, and our H20 wooden beams are a strong proof of our commitment to providing versatile and reliable building solutions.

H Beam Information

|

Name |

Size |

Materials |

Length( m) |

Middle Bridge |

|

H Timber Beam |

H20x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

H16x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

|

|

H12x80mm |

Poplar/Pine |

0-8m |

27mm/30mm |

H Beam/I Beam Features

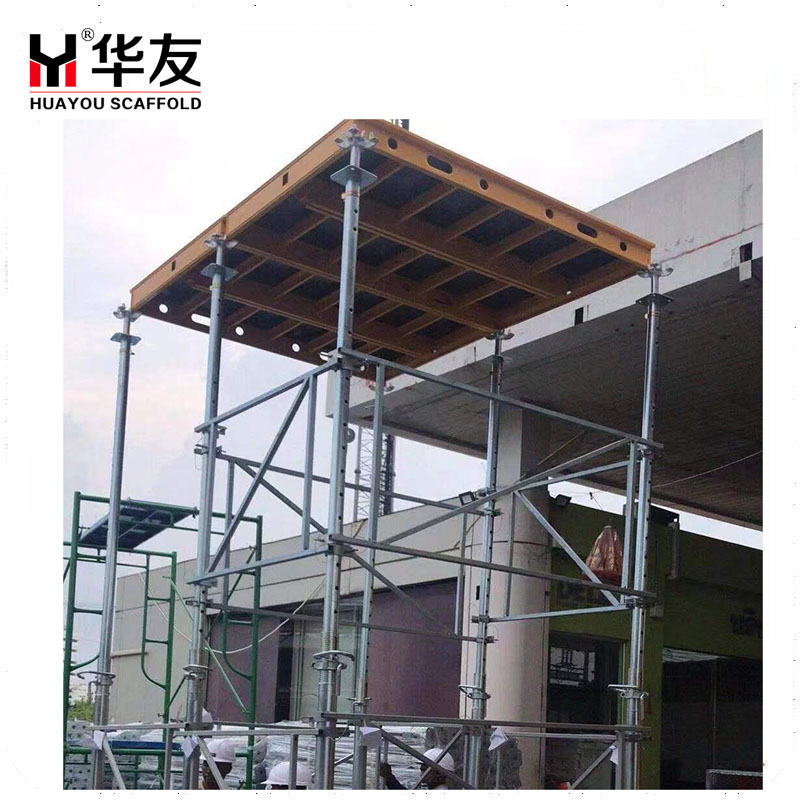

1. I-beam is an important component of the internationally used building formwork system. It has the characteristics of light weight, high strength, good linearity, not easy to deform, surface resistance to water and acid and alkali, etc. It can be used all year round, with low cost amortization expenses; it can be used with professional formwork system products at home and abroad.

2. It can be widely used in various formwork systems such as horizontal formwork system, vertical formwork system (wall formwork, column formwork, hydraulic climbing formwork, etc.), variable arc formwork system and special formwork.

3. The wooden I-beam straight wall formwork is a loading and unloading formwork, which is easy to assemble. It can be assembled into formworks of various sizes within a certain range and degree, and is flexible in application. The formwork has high rigidity, and it is very convenient to connect the length and height. The formwork can be poured at a maximum of more than ten meters at a time. Because the formwork material used is light in weight, the whole formwork is much lighter than the steel formwork when assembled.

4. The system product components are highly standardized, have good reusability, and meet environmental protection requirements.

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.4 | Electro-Galv. |

| Round nut |  |

15/17mm | 0.45 | Electro-Galv. |

| Round nut |  |

D16 | 0.5 | Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | Electro-Galv. | |

| Washer |  |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

Product Introduction

Also known as I-beams or H-beams, this innovative product is designed to provide superior support for light-load projects while ensuring cost-effectiveness.

While traditional H-beams are known for their high load-bearing capacity, our H20 Wood Beams are a reliable alternative that reduces costs without compromising safety and performance. Whether you are undertaking a small renovation or a large construction project, our H20 wooden beams are the ideal choice when balancing performance and cost.

Our Wooden H20 beams are built with a commitment to improving construction safety at their core. Scaffolding timber plays a vital role in improving site safety and our beams are engineered to the highest standards. Strong, durable and lightweight, they are not only easy to handle and install, but also contribute to a safer working environment. When you choose our Wooden H20 beams, you are investing in a product that maintains structural integrity while taking into account the well-being of your employees.

Product Advantage

One of the main advantages of using wooden H20 beam is their light weight. Unlike traditional H-beams, which are designed for high load-bearing capacity, wooden beams are easier to handle and transport. This can significantly reduce on-site labor costs and time, making them ideal for smaller projects. In addition, wooden beams are often more cost-effective, allowing contractors to save costs without compromising quality.

Another benefit is environmental protection. Wood is a renewable resource and, if sourced sustainably, can be a more environmentally friendly choice compared to steel. This fits in with the growing trend toward sustainable building practices and is attractive to environmentally conscious clients.

Product Shortcoming

Wood beams are not suitable for all types of projects, especially those that require heavy loads or extreme durability. They are more susceptible to weather, insects and rot, so additional maintenance or treatment may be required.

FAQS

Q1:What are wooden H20 beams?

Lightweight and strong, wooden H20 beams are primarily used for scaffolding and formwork. Unlike traditional H-shaped steel beams, which are known for their high load-bearing capacity, wooden H20 beams are ideal for projects that require less weight and load-bearing strength. This makes them a cost-effective solution for many construction needs.

Q2:Why choose wooden H20 beams?

1. Cost-effective: Wooden H20 beams are generally more affordable than steel beams, making them a popular choice for budget-conscious projects.

2. Light weight: Light weight makes it easier to carry and install, thus reducing labor costs and time on site.

3. Widely Used: These beams can be used in a variety of construction scenarios, from scaffolding to formwork, providing flexibility to contractors.

Q3:FAQs about Scaffolding Timber

1. How do I know if wooden H20 beams are suitable for my project?

- Evaluate the load requirements of your project. If the project falls into the light load category, H20 wood beams may be a suitable choice.

2. Are wooden H20 beams durable?

- Yes, wooden H20 beams can provide excellent durability and performance if properly maintained.

3. Where can I buy wooden H20 beams?

- Our company was established in 2019 and our business scope has covered nearly 50 countries around the world. We have established a complete procurement system to ensure that you can easily obtain high-quality scaffolding timber.