Steel Euro Formwork | Heavy-Duty Modular Shuttering Systems

Steel Formwork Components

|

Name |

Width (mm) |

Length (mm) |

|||

|

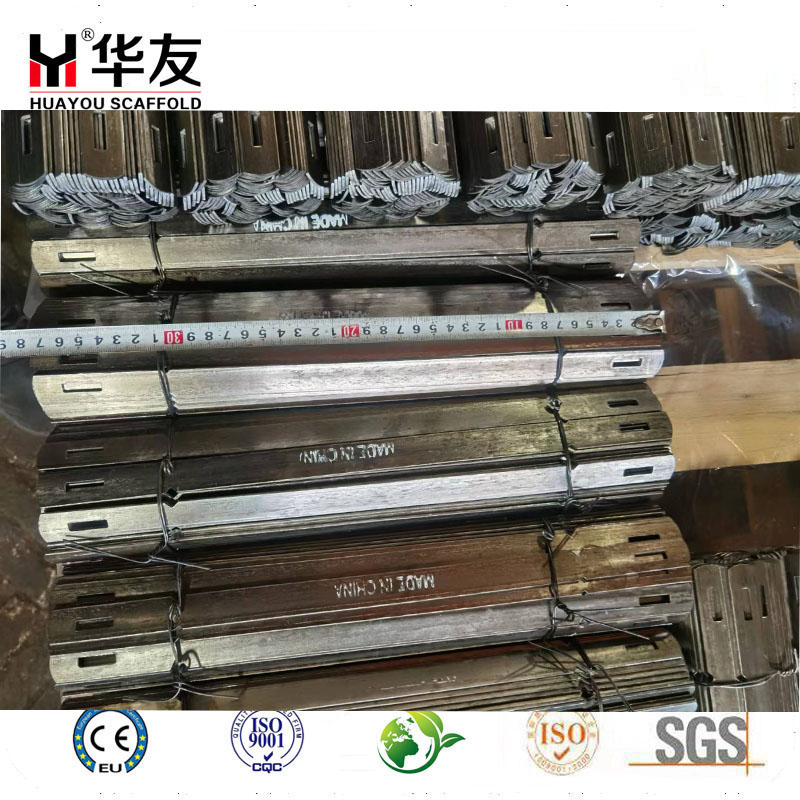

Steel Frame |

600 |

550 |

1200 |

1500 |

1800 |

|

500 |

450 |

1200 |

1500 |

1800 |

|

|

400 |

350 |

1200 |

1500 |

1800 |

|

|

300 |

250 |

1200 |

1500 |

1800 |

|

|

200 |

150 |

1200 |

1500 |

1800 |

|

|

Name |

Size (mm) |

Length (mm) |

|||

|

In Corner Panel |

100x100 |

900 |

1200 |

1500 |

|

|

In Corner Panel |

100x150 |

900 | 1200 | 1500 | |

|

In Corner Panel |

100x200 |

900 | 1200 | 1500 | |

|

Name |

Size(mm) |

Length (mm) |

|||

|

Outer Corner Angle |

63.5x63.5x6 |

900 |

1200 |

1500 |

1800 |

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.4 | Electro-Galv. |

| Round nut |  |

15/17mm | 0.45 | Electro-Galv. |

| Round nut |  |

D16 | 0.5 | Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | Electro-Galv. | |

| Washer |  |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

Advantages

1.Outstanding engineering design and structural strength

Sturdy and durable frame: The main frame is made of high-quality steel (such as F-shaped, L-shaped, and triangular reinforcing ribs), ensuring that the formwork can withstand tremendous pressure during the concrete pouring process without deformation or leakage of slurry.

Standardization and modularization: We offer a variety of standard-sized panels ranging from 200mm to 600mm in width, 1200mm in height, and 1500mm in height. The modular design makes assembly flexible and efficient, enabling quick adaptation to various wall and column sizes and significantly enhancing construction efficiency.

Systematic solution: Not only does it provide flat formwork, but also offers inner corner plates, outer corner formwork, through-wall sleeves and support systems, forming a complete construction system to ensure precise structural corners and high overall stability.

2. Multi-functional application and efficient construction

Integrated construction collaboration: As a manufacturer specializing in scaffolding and formwork systems, we have a deep understanding of the need for their collaborative operations on construction sites. Our product design is convenient for use in conjunction with scaffolding systems, achieving safe and efficient synchronization of high-altitude operations and concrete pouring.

Customized production capacity: Supports non-standard customized production based on customer engineering drawings, perfectly matching special structures and complex design requirements, helping customers save on-site modification time and costs.

3. Reliable quality and global service

The manufacturing principle of "Quality first" : Located in Tianjin, China - a significant national manufacturing base for steel and scaffolding products, we enjoy a unique industrial chain advantage. We strictly control from raw materials to processes to ensure the quality of our products before they leave the factory.

Convenient global logistics: Relying on the superior geographical location of Tianjin as a port city, our products can be exported to the world quickly and economically by sea, and have successfully served multiple markets such as Southeast Asia, the Middle East, Europe and America.

Customer-centered service philosophy: We adhere to the principle of "Quality first, Customer Supreme, and Ultimate Service". Not only do we provide high-quality products, but we are also committed to offering professional technical support and solutions. By enhancing work efficiency and reducing time costs, we aim to achieve mutual benefit and win-win results with our customers.

FAQS

1. What are the standard sizes of your Steel Euro Formwork panels?

Our Steel Euro Formwork is available in modular sizes for efficiency. Common panel sizes include widths from 200mm to 600mm and heights of 1200mm or 1500mm, such as 600x1200mm and 500x1500mm. We can also produce custom sizes based on your project drawings.

2. What main steel frame components are used in your formwork system?

Our formwork features a robust steel frame constructed with key components like F bars, L bars, and triangle bars. This design, combined with the plywood face, ensures high strength, durability, and stability for concrete construction projects.

3. Can you supply a complete formwork system, not just panels?

Yes, we provide a complete Steel Euro Formwork system. In addition to standard panels, our range includes corner panels (inner and outer), necessary angles, pipes, and pipe supports to meet all the shuttering needs of a construction site.

4. What is your advantage as a Steel Formwork and Scaffolding manufacturer?

Located in Tianjin, a major industrial and port city, we benefit from a strong manufacturing base and excellent logistics for global shipping. Our expanded product range allows us to offer integrated solutions for both formwork and scaffolding, improving on-site efficiency and reducing overall time costs for our clients.

5. Which markets do you export to, and what is your business principle?

We export worldwide, including Southeast Asia, the Middle East, Europe, and America. We operate on the principle of "Quality First, Customer Foremost, and Service Utmost," dedicating ourselves to meeting your requirements and fostering mutually beneficial cooperation.