Steel Euro Formwork Improves Construction Efficiency

Company Introduction

Since our founding in 2019, we have been committed to expanding our global presence. Our professional export company has successfully served clients in nearly 50 countries and has earned a good reputation for its high quality and reliability. Over the years, we have established a sound procurement system to ensure on-time delivery and provide excellent service, allowing our clients to focus on what they do best - construction.

Main feature

The main feature of Steel Euro Formwork is its sturdy structure, which is made of steel frame and high-quality plywood. This combination not only ensures strength, but also provides a reliable surface for concrete pouring.

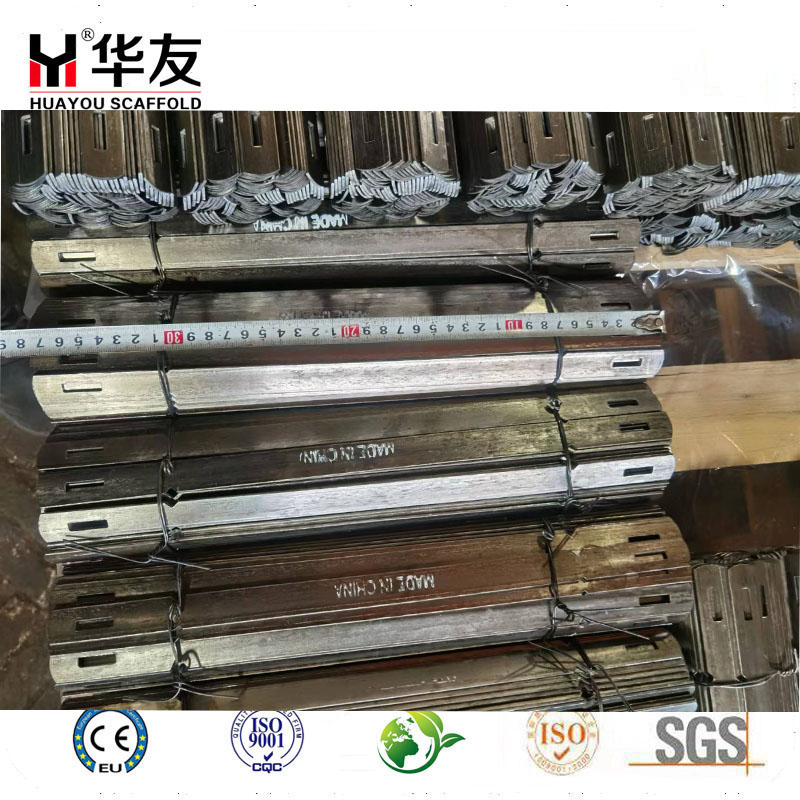

The steel frame is composed of various components, including F-type steel bars, L-type steel bars and triangular steel bars, which enhances its structural integrity and can adapt to different construction needs.

Steel Euro Formwork is available in a variety of standard sizes including 600x1200mm, 500x1200mm, 400x1200mm, 300x1200mm, 200x1200mm, as well as larger sizes such as 600x1500mm, 500x1500mm, 400x1500mm, 300x1500mm and 200x1500mm. This variety enables contractors to select the most appropriate size for their specific project needs, making it an ideal choice for both large and small construction projects.

Steel Formwork Components

|

Name |

Width (mm) |

Length (mm) |

|||

|

Steel Frame |

600 |

550 |

1200 |

1500 |

1800 |

|

500 |

450 |

1200 |

1500 |

1800 |

|

|

400 |

350 |

1200 |

1500 |

1800 |

|

|

300 |

250 |

1200 |

1500 |

1800 |

|

|

200 |

150 |

1200 |

1500 |

1800 |

|

|

Name |

Size (mm) |

Length (mm) |

|||

|

In Corner Panel |

100x100 |

900 |

1200 |

1500 |

|

|

Name |

Size(mm) |

Length (mm) |

|||

|

Outer Corner Angle |

63.5x63.5x6 |

900 |

1200 |

1500 |

1800 |

Formwork Accessories

| Name | Pic. | Size mm | Unit weight kg | Surface Treatment |

| Tie Rod |  |

15/17mm | 1.5kg/m | Black/Galv. |

| Wing nut |  |

15/17mm | 0.4 | Electro-Galv. |

| Round nut |  |

15/17mm | 0.45 | Electro-Galv. |

| Round nut |  |

D16 | 0.5 | Electro-Galv. |

| Hex nut |  |

15/17mm | 0.19 | Black |

| Tie nut- Swivel Combination Plate nut |  |

15/17mm | Electro-Galv. | |

| Washer |  |

100x100mm | Electro-Galv. | |

| Formwork clamp-Wedge Lock Clamp |  |

2.85 | Electro-Galv. | |

| Formwork clamp-Universal Lock Clamp |  |

120mm | 4.3 | Electro-Galv. |

| Formwork Spring clamp |  |

105x69mm | 0.31 | Electro-Galv./Painted |

| Flat Tie |  |

18.5mmx150L | Self-finished | |

| Flat Tie |  |

18.5mmx200L | Self-finished | |

| Flat Tie |  |

18.5mmx300L | Self-finished | |

| Flat Tie |  |

18.5mmx600L | Self-finished | |

| Wedge Pin |  |

79mm | 0.28 | Black |

| Hook Small/Big |  |

Painted silver |

Product Advantage

One of the main advantages of Steel Euro Formwork is its durability. The steel frame consists of various components such as F-beam, L-beam and triangle steel, which provide excellent strength and stability. This makes it ideal for heavy construction projects. In addition, its standard sizes (from 200x1200 mm to 600x1500 mm) are flexible and can be customized according to project needs.

Another significant advantage is the speed of assembly and disassembly. The modular design of Steel Euro Formwork allows for quick installation, which significantly reduces labor costs and shortens project duration. In addition, its reusable nature allows it to be used in multiple projects, making it a cost-effective solution in the long run.

Product shortcoming

Despite the many advantages of steel formwork, there are also some disadvantages. One notable one is its weight. Steel frames are heavy and bulky, making them more challenging to transport and handle than lighter alternatives. This can lead to increased labor costs and pose safety risks on site.

Additionally, while the durability and reusability of steel Euroforms may justify the initial investment, their upfront costs can be higher than other formwork options. This can be prohibitive for smaller contractors or those on a budget.

FAQS

Q1:What is Steel Euro Formwork?

Steel Euro Formwork is a sturdy building system that is made up of a combination of steel frame and plywood. This combination provides a strong and reliable formwork solution that can withstand the rigors of construction. The steel frame consists of various components, including F-shaped bars, L-shaped bars and triangular bars, which enhance its structural performance.

Q2:What are the standard sizes?

Steel Euro formwork is available in a variety of standard sizes to meet different project needs. Common sizes include 600x1200mm, 500x1200mm, 400x1200mm, 300x1200mm, 200x1200mm, and larger sizes such as 600x1500mm, 500x1500mm, 400x1500mm, 300x1500mm and 200x1500mm. These size diversity provides flexibility for design and application.

Q3:Why Choose Steel Euro Formwork?

One of the main advantages of steel Euro formwork is its durability. Unlike traditional wooden formwork, steel formwork can be reused many times without causing severe wear and tear. This not only reduces costs but also minimizes waste, making it an environmentally friendly choice. In addition, the precision of steel components ensures a high-quality finish to the concrete structure.