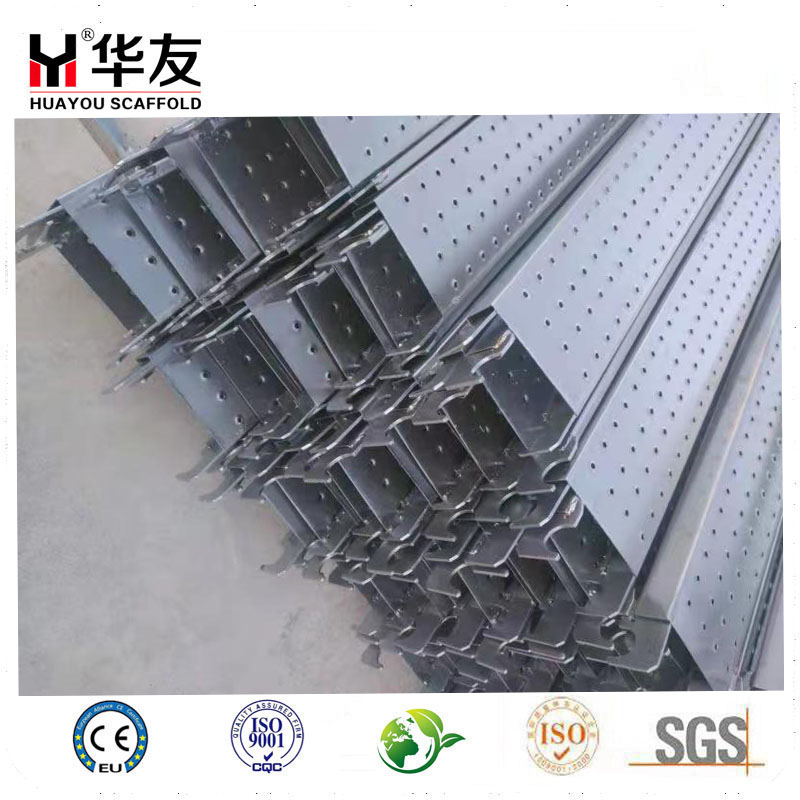

Steel Planks With Hook: Durable Perforated Decking for Secure Scaffolding

As a mature manufacturer of platforms, we exclusively supply various hook-equipped steel platforms (commonly known as catwalks), which are used to connect frame scaffolding to form safe passageways or modular tower platforms. We not only support custom production based on your drawings, but also can provide related accessories for overseas manufacturers.

Size as following

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (mm) |

|

Scaffolding Plank with hooks |

200 |

50 |

1.0-2.0 |

Customized |

|

210 |

45 |

1.0-2.0 |

Customized |

|

|

240 |

45 |

1.0-2.0 |

Customized |

|

|

250 |

50 |

1.0-2.0 |

Customized |

|

|

260 |

60/70 |

1.4-2.0 |

Customized |

|

|

300 |

50 |

1.2-2.0 | Customized | |

|

318 |

50 |

1.4-2.0 | Customized | |

|

400 |

50 |

1.0-2.0 | Customized | |

|

420 |

45 |

1.0-2.0 | Customized | |

|

480 |

45 |

1.0-2.0 |

Customized |

|

|

500 |

50 |

1.0-2.0 |

Customized |

|

|

600 |

50 |

1.4-2.0 |

Customized |

Advantages

Flexible customization to meet global demands

Our mature production line not only offers standard specifications (such as 420/450/500mm width) of products, but also supports deep customization (ODM). No matter where you come from, whether it's Asia, South America or any other market, as long as you provide design drawings or specific details, we can "manufacture as per your requirements" and precisely match your project requirements with local standards. Truly achieving the service commitment of "Tell us, then we do make it".

2. Safe and efficient, with thoughtful and practical design

Safe and convenient: The unique hook design enables it to securely attach to the crossbars of the frame scaffolding. It can be quickly assembled between two frames to form a stable "air bridge" or working platform, greatly facilitating the movement and work of workers, and enhancing construction efficiency and safety.

Multifunctional application: It is suitable for traditional frame scaffolding systems and also perfectly matches modular scaffolding towers, serving as a safe and reliable working platform.

3. Outstanding quality, with complete and reliable certifications

Material and Craftsmanship: Made of high-strength and stable steel, ensuring strength and durability. Offers various surface treatments such as hot-dip galvanizing (H.D.G) and electro-galvanizing (E.G), providing corrosion and rust prevention, and extending service life.

Authoritative Certification: The factory has obtained ISO system certification. The products can undergo international authoritative tests such as SGS according to customer requirements, and they meet strict industry quality standards. The quality is reliable.

4. Strong comprehensive strength and complete service guarantee

Cost advantage: Leveraging our robust factories located in the core manufacturing base of China and large-scale production, we can offer highly competitive prices, helping you save project costs.

Professional Team: Comprises an active sales team and a professional quality control (QC) team, providing efficient and professional full-service support from communication to delivery.

Global Supply: Not only do we export finished jumpers, but we can also supply jumpers' components to overseas manufacturing enterprises, demonstrating our comprehensive supply chain capabilities and flexibility.

5. Firm cooperation philosophy, creating long-term value together

We adhere to the management principles of "quality first, service priority, continuous improvement, and innovation to meet customer needs", with the quality goal of "zero defects, zero complaints". Our ultimate goal is to become the leading brand in the industry, winning the continuous trust of both new and old customers with reliable products (such as the popular scaffold steel posts, etc.), and we sincerely invite global partners to cooperate and create a better future together.

Basic information

1. Brand and Material Commitment

Brand Logo: Huayou (Huayou) - A professional scaffolding brand derived from the core steel manufacturing base in China, symbolizing reliability and strength.

Core Materials: Strictly using Q195 and Q235 grade steel. This material selection implies:

Q195 (Low-carbon Steel): Exhibits excellent plasticity and toughness, and is easy to be shaped and processed. This ensures that key structures such as hooks maintain their strength even after bending.

Q235 (ordinary carbon structural steel): It has a higher yield strength and excellent comprehensive mechanical properties, providing the core load-bearing capacity and structural stability for the platform. The scientific application of these two materials achieves the optimal balance of cost, performance and durability.

2. Professional-level anti-corrosion protection

Surface treatment: Offers two processes - hot-dip galvanizing and pre-galvanizing - to meet different budget and anti-corrosion grade requirements.

Hot-dip galvanizing: The coating is thick (typically ≥ 85 μm), has a long-lasting anti-corrosion performance, and is particularly suitable for outdoor or industrial environments with high humidity and corrosive conditions, providing "fortress-level" protection.

Pre-galvanizing: The substrate has undergone galvanizing before rolling, resulting in a uniformly smooth surface with stable anti-corrosion properties. It offers high cost-effectiveness and is an excellent choice for standard operating environments.

3. Optimized Packaging and Logistics

Product Packaging: Steel bands are used for bundling. This packaging method is sturdy and compact, effectively preventing deformation, scratches and unpacking during transportation, ensuring that the products arrive at the construction site in their original condition, reducing losses and facilitating on-site storage and distribution.

4. Flexible and efficient supply guarantee

Minimum order quantity: 15 tons. This is a relatively friendly threshold for small and medium-sized projects or traders, which not only ensures the scale effect of production but also reduces the pressure on customers for trial orders and stock preparation.

Delivery cycle: 20-30 days (depending on the specific quantity). Relying on the efficient supply chain system of the Tianjin production base adjacent to the port, we can achieve a rapid response from receiving orders, production to shipment, ensuring stable and timely delivery to global customers.

1.What is a steel plank with hooks (Steel Planks With Hook)? In which markets is it mainly used?

A steel plank with hooks (also known as "catwalk") is a platform laying board mainly used in frame-type scaffolding systems. It is directly hooked onto the crossbars of the frame through the hooks on the board side, forming a stable bridge passage between two frames, facilitating safe work for workers on it. This product is mainly supplied to markets in Asia, South America, etc., and is also commonly used as a working platform for modular scaffolding towers.

2. What are the standard sizes of this type of scaffold platform? How is it mainly applied?

The common hook-type scaffold platform has a width of 45 millimeters. The lengths usually include specifications such as 420 millimeters, 450 millimeters, and 500 millimeters. When using it, simply fix the hooks at both ends of the platform to the crossbars of adjacent scaffolding frames, and a safe working passage can be quickly built. The installation is convenient and the stability is reliable.

3. Do you support custom production based on customer drawings or designs?

Yes. We have a mature steel platform production line. Not only do we offer standard products, but we also fully support customized production based on customers' own designs or detailed drawings (ODM/OEM). Moreover, we can export platform-related accessories to manufacturing enterprises in overseas markets, and will do our best to meet your diverse needs.

4. How do you ensure the quality and service of your products?

We have always adhered to the principle of "quality first, service foremost". All products are made of sturdy steel and have passed ISO and SGS certifications. We have a professional quality control system, a robust production facility, and an efficient sales and service team. We are committed to providing high-quality products with various surface treatments such as hot-dip galvanizing and electro-galvanizing at competitive prices to our customers.

5. What are the advantages of cooperating with your company?

Our core advantages include: competitive prices, a professional sales team, strict quality control, strong factory production capacity, and high-quality services and products. We focus on providing a full range of products including disc scaffolding and steel supports to global customers, and our quality goal is "zero defects, zero complaints". We look forward to cooperating with you and jointly creating development.