Steel Shoring Prop: High-Capacity Adjustable Support System

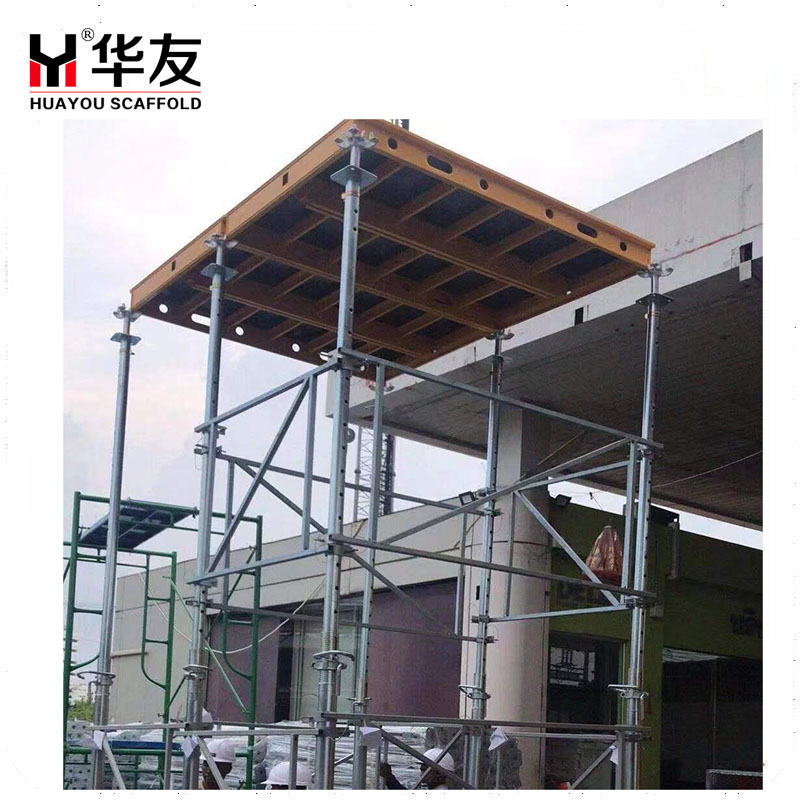

This steel support (also known as formwork support or adjustable pillar) achieves free adjustment of its closed and open heights through a precisely machined telescopic structure, perfectly meeting the various elevation requirements of construction sites. The accompanying square tube support tripod and customizable fork heads, along with H-shaped steel and other components, work together to form an overall structure connected by horizontal steel pipes, jointly constituting a stable and reliable high-load formwork support system.

Size as following

|

Item |

Min.-Max. |

Inner Tube(mm) |

Outer Tube(mm) |

Thickness(mm) |

|

Heany Duty Prop |

1.8-3.2m |

48/60 |

60/76 |

1.8-4.75 |

|

2.0-3.6m |

48/60 |

60/76 |

1.8-4.75 |

|

|

2.2-3.9m |

48/60 |

60/76 |

1.8-4.75 |

|

|

2.5-4.5m |

48/60 |

60/76 |

1.8-4.75 |

|

|

3.0-5.5m |

48/60 |

60/76 |

1.8-4.75 |

Advantages

1. Outstanding load-bearing capacity: The heavy-duty pillars are made of high-strength Q235/Q355 steel tubes, specially designed for the high-load requirements of concrete projects. They ensure the safety and stability of the support system and possess excellent load-bearing performance.

2. Superior materials and craftsmanship: All components are made of high-quality steel and are treated for rust prevention through advanced processes such as powder coating or hot-dip galvanizing. This significantly extends the product's service life in harsh construction environments and ensures long-term reliability.

3. Highly flexible and adjustable: The column adopts an inner and outer tube sleeve type telescopic design. By flexibly adjusting the closed height and open height, it can precisely adapt to different construction height requirements, and is a highly versatile adjustable vertical support.

4. Systematic and stable solution: The pillar can be combined with H-shaped steel, tripod supports and other accessories, and is connected horizontally with steel pipes and fasteners to form an overall stable support system, effectively ensuring the overall safety and stability of the formwork system.

5. Comprehensive Customization Service: We can flexibly customize the closed/open height of the pillars, the size of the tripod (such as 650/750/800mm), and various template accessories like the fork head, according to your specific project requirements. We will provide a completely matching solution.

6. Multi-functional and wide applicability: This product is also known as scaffold posts, support jacks, formwork supports, etc. It is a type of adjustable telescopic pillar widely used in concrete formwork support systems, capable of meeting various construction support scenarios.

Basic information

1.Brand: Huayou

2.Materials: Q235, Q355 pipe

3.Surface treatment: hot dipped galvanized , electro-galvanized, painted, powder coated.

4.Production procedure: material---cut by size---punching hole---welding ---surface treatment

5.Package: by bundle with steel strip or by pallet

6.Delivery time: 20-30days depends on the quantity

FAQS

1.What is a scaffolding steel prop/shoring prop?

A scaffolding steel prop/shoring prop is a adjustable vertical tubular support system, mainly used for supporting concrete formwork. It is usually composed of inner tube, outer tube, sleeve, top and bottom plates, nuts and locking pins, etc. Due to its adjustable height, it is also called a telescopic support or formwork support.

2. Why does the steel support bracket have a strong bearing capacity?

This system adopts a heavy-duty support design. It is mainly manufactured using high-strength steel pipes such as Q235 or Q355, and is treated for rust prevention through processes like powder coating or hot-dip galvanizing. As a result, it has high compressive strength and durability, and is particularly suitable for high-load supports in concrete projects.

3. How does the support system maintain overall stability?

Apart from the vertical steel support brackets, the system also includes H-shaped steel, triangular supports, and other accessories. It is reinforced horizontally through steel pipes and connecting pieces, forming an overall stable support framework that ensures no deviation or deformation occurs under high loads.

4. Can the height of the support legs be adjusted?

Yes. The steel support jacks are of telescopic design. They can be adjusted to change the closed height and open height according to the construction requirements to adapt to different support heights. The operation is flexible and they are suitable for various construction site conditions.

5. Can custom support accessories, such as tripods or fork heads, be provided?

Yes. We offer customized services. Tripods are usually made of square tubes. Common heights such as 650mm, 750mm, and 800mm can be customized as per customer requirements. Template accessories such as support fork heads can also be designed and produced according to the specific requirements of the customers.