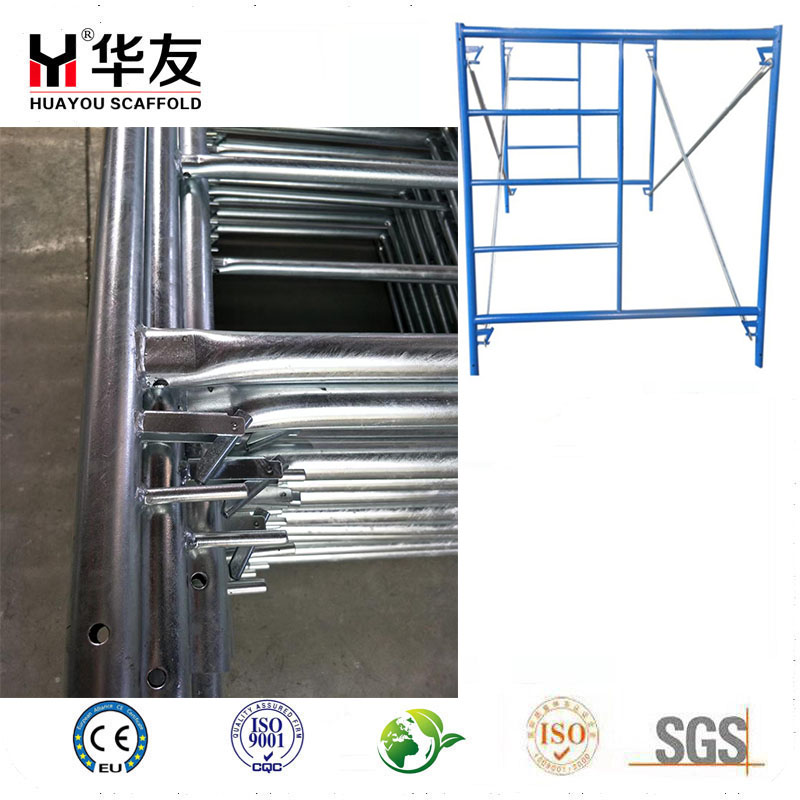

Adjustable Steel Frame Scaffolding | Heavy Duty Construction Scaffold System

Scaffolding Frames

1. H Frame / Ladder Frame / Support Frame Specification

| Name | Size (W+H) mm | Main Tube Dia mm | Other Tube Dia mm | steel grade | surface treatment | Customized |

| H Frame/Ladder Frame | 1219x1930 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes |

| 762x1930 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1524x1930 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1219x1700 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 950x1700 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1219x1219 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1524x1219 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1219x914 | 42.7mm/48.3mm | 25.4mm/42.7mm/48.3mm | Q195/Q235/Q355 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| Support Frame | 1220x1830 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes |

| 1220x1520 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes | |

| 910x1220 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes | |

| 1150x1200 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes | |

| 1150x1800 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes | |

| 1150x2000 | 48.3mm/50mm/60.3mm | 48.3mm/50mm/60.3mm | Q235/Q355 | Painted/Powder Coated/Hot Dip Galv | Yes | |

| Cross Brace | 1829x1219x2198 | 21mm/22.7mm/25.4mm | Q195-Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | |

| 1829x914x2045 | 21mm/22.7mm/25.4mm | Q195-Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| 1928x610x1928 | 21mm/22.7mm/25.4mm | Q195-Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| 1219x1219x1724 | 21mm/22.7mm/25.4mm | Q195-Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| 1219x610x1363 | 21mm/22.7mm/25.4mm | Q195-Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| 1400x1800x2053.5 | 26.5mm | Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| 765x1800x1683.5 | 26.5mm | Q235 | Painted/Pre-Galv./Powder Coated/Hot Dip Galv | Yes | ||

| Joint Pin | 35mmx210mm/225mm | Q195/Q235 | Pre-Galv. | Yes | ||

| 36mmx210mm/225mm | Q195/Q235 | Pre-Galv. | Yes | |||

| 38mmx250mm/270mm | Q195/Q235 | Pre-Galv./Hot Dip Galv. | Yes |

2. Catwalk / Plank with Hooks

Catwalk as a platform of frame system can support workers to make building, maintaince or repair. Normally, will use hooks to fix between frames.

We can produce or customized catwalk base on customers' requirements. Width, thickness and length all can be changed.

| Name | Size Width mm | Length mm | Surface Treatment | Steel Grade | Customized |

| Catwalk/ PLank with Hooks | 240mm/480mm | 1000mm/1800mm/1829mm/2000mm | Pre-Galv./Painted/Powder coated/Hot Dip Galv. | Q195/Q235 | Yes |

| 250mm/500mm | 1000mm/1800mm/1829mm/2000mm | Pre-Galv./Painted/Powder coated/Hot Dip Galv. | Q195/Q235 | Yes | |

| 300mm/600mm | 1000mm/1800mm/1829mm/2000mm | Pre-Galv./Painted/Powder coated/Hot Dip Galv. | Q195/Q235 | Yes | |

| 350mm/360mm/400mm | 1000mm/1800mm/1829mm/2000mm | Pre-Galv./Painted/Powder coated/Hot Dip Galv. | Q195/Q235 | Yes |

3. Jack Base and U Jack

| Name | Dia mm | Length mm | Steel Plate | Surface Treatment | Customized |

| Base Jack Solid | 28mm/30mm/32mm/34mm/35mm/38mm | 350mm/500mm/600mm/750mm/1000mm | 120x120mm/140x140mm/150x150mm | Painted/Electro-Galv./Hot Dip Galv. | Yes |

| Base Jack Hollow | 34mm/38mm/48mm | 350mm/500mm/600mm/750mm/1000mm | 120x120mm/140x140mm/150x150mm | Painted/Electro-Galv./Hot Dip Galv. | Yes |

| U Head Jack Solid | 28mm/30mm/32mm/34mm/35mm/38mm | 350mm/500mm/600mm/750mm/1000mm | 150x120x50mm/120x80x40mm/200x170x80mm | Painted/Electro-Galv./Hot Dip Galv. | Yes |

| U Head Jack Hollow | 34mm/38mm/48mm | 350mm/500mm/600mm/750mm/1000mm | 150x120x50mm/120x80x40mm/200x170x80mm | Painted/Electro-Galv./Hot Dip Galv. | Yes |

4. Castor Wheel

For frame wheel, there are so many types for choosing.

We can produce almost scaffolding wheel base on customers' requirements.

| Name | Size mm | inch | Material | Loading Capacity |

| Wheel | 150mm/200mm | 6’’/8’’ | Rubber+steel/PVC+steel | 350kg/500kg/700kg/1000kg |

Advantages

1. High market recognition: As a classic frame product in the American and Latin American markets, the ladder frame (H-shaped frame) is maturely designed, widely applied, and deeply trusted by global customers.

2. Wide range of application scenarios: It is not only used in construction and maintenance to provide workers with a safe working platform, but also its heavy-duty design can support H-shaped steel beams and concrete formwork, making it suitable for various complex engineering projects.

3. Fully customized production: We possess strong design and production capabilities, capable of manufacturing all types of scaffolding frames based on customers' specific requirements and drawing details, achieving true "customization on demand".

4. Complete product line, one-stop supply: In addition to main frames and ladders, we also offer various connection system frames such as quick locks, flip plate locks, and self-locks. Moreover, we can provide different steel grades (Q195/Q235/Q355) and surface treatments (powder coating, pre-galvanizing, hot-dip galvanizing, etc.) according to requirements.

5. Complete industrial chain and geographical advantage: The company is located in Tianjin, the largest steel and scaffolding production base in China, and has a complete supply chain from processing to production, ensuring quality and production capacity. Meanwhile, as an important port city, Tianjin offers extremely convenient and efficient global logistics and export channels, significantly reducing transportation costs and time.

6. Strict quality and service philosophy: We adhere to the principle of "Quality First, Customer Supreme, Service Ultimate", strictly controlling from raw materials to finished products. We have successfully exported our products to multiple markets in Southeast Asia, the Middle East, Europe, America, etc. We have rich experience in international project cooperation and are committed to achieving long-term mutually beneficial and win-win cooperation.

FAQS

1. What is H-type /Ladder Frame scaffolding? What is its main use?

H-type /Ladder Frame is a core frame of portal scaffolding that is very popular in the markets of the United States and Latin America. Its main purpose is to provide a safe working support platform for construction or maintenance work. In some projects, heavy-duty Ladder frames are also used to support H-shaped steel beams and concrete formwork.

2. What types of scaffolding frames does your company produce?

We specialize in manufacturing all kinds of scaffolding systems and have a complete product line. In addition to the standard portal frames, we also produce main frames, H-shaped /Ladder frames, bridge frames, masonry frames, and frames for various quick-lock systems (such as latch locks, flip locks, speed locks, pioneer locks, etc.).

3. What are the options for surface treatment and material specifications of the product?

To meet the demands of diverse markets around the world, we offer a variety of surface treatment processes, including powder coating, pre-galvanizing and hot-dip galvanizing. In terms of steel raw materials, we use various steel grades such as Q195, Q235, and Q355.

4. How does your company ensure product quality and supply capacity?

We are located in Tianjin, the largest manufacturing base for steel and scaffolding products in China. As a port city, it is convenient for global transportation. We have established a complete processing and production chain, strictly adhering to the principle of "quality first, Customer Supreme, Service Excellent", and can produce all types of frames according to the specific requirements and drawing details of customers.

5. To which markets are the products mainly exported?

At present, our products have been successfully exported to many regions around the world, including Southeast Asia, the Middle East, Europe and the American markets. We are committed to meeting the needs of global customers and promoting mutually beneficial cooperation.