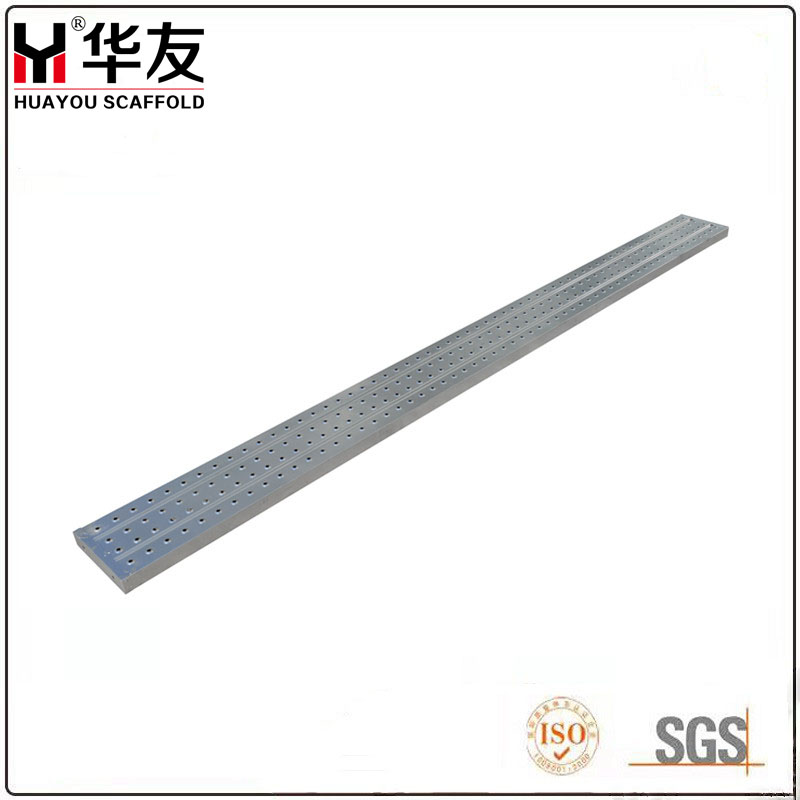

Durable Metal Plates Suitable For Various Construction Projects

What is scaffold plank / Metal Plank

Scaffolding boards (also known as metal plates, steel decks, or walking platforms) are load-bearing components used to build scaffolding working platforms, replacing traditional wooden or bamboo boards. They are made of high-strength steel and are widely used in:

1. Construction (high-rise buildings, commercial projects, residential renovations)

2. Ship and Ocean Engineering (Shipbuilding, Oil Platforms)

3. Industrial fields such as power and petrochemicals

Size as following

The lightweight steel treads, specially designed for efficient construction, combine strength with portability - rust-proof and durable, ready to use upon installation, and can be easily matched with various scaffolding systems, making high-altitude operations safer and more time-saving

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

200 |

50 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

Products Advantages

1.Outstanding durability and load-bearing capacity

Made of high-strength steel and processed with precision engineering, it can withstand heavy use and extreme construction environments;Hot-dip galvanizing process (optional) provides additional rust protection, extends service life, and is suitable for humid, Marine and chemical environments;The static load capacity is up to XXX kg (can be supplemented according to actual data), and the dynamic load complies with international standards such AS EN 12811/AS/NZS 1576.

2. Comprehensive security guarantee

The anti-slip surface design (concave-convex texture/sawtooth texture) ensures that workers can still work safely in wet and slippery conditions such as rain, snow and oil stains;Modular connection system: Pre-punched M18 bolt holes, which can be quickly locked with other steel plates or scaffolding components, and equipped with 180mm black and yellow warning foot plates (meeting fall protection standards) to prevent tools/personnel from slipping;Full-process quality inspection: From raw materials (chemical/physical testing of 3,000 tons of inventory per month) to finished products, all undergo strict load tests to ensure 100% acceptance.

3. Efficient installation and wide compatibility

Standardized hole position design, compatible with mainstream tubular scaffolding systems (such as coupler type, portal type, and disk buckle type), supports flexible adjustment of platform width;Lightweight yet high-strength steel plates (approximately XX kg/㎡) reduce handling time, enhance assembly and dismantling efficiency, and save over 30% of working hours compared to traditional wooden or bamboo boards;It is applicable to multiple scenarios such as construction, shipbuilding, oil platforms, and power maintenance, especially suitable for high-altitude, narrow or corrosive environments.