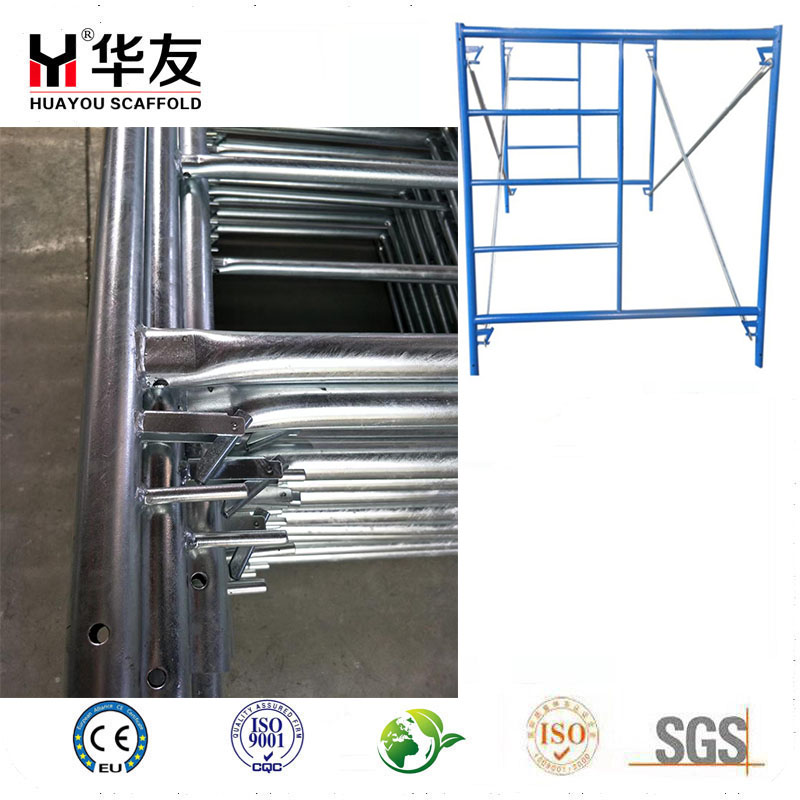

Heavy-Duty Scaffolding Main Frame – Industrial Construction Support System

Scaffolding Frames

1. Scaffolding Frame Specification-South Asia Type

| Name | Size mm | Main Tube mm | Other Tube mm | steel grade | surface |

| Main Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1524 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 914x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| H Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1219 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x914 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| Horizontal/Walking Frame | 1050x1829 | 33x2.0/1.8/1.6 | 25x1.5 | Q195-Q235 | Pre-Galv. |

| Cross Brace | 1829x1219x2198 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | |

| 1829x914x2045 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1928x610x1928 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x1219x1724 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x610x1363 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. |

2. Walk Thru Frame -American Type

| Name | Tube and Thickness | Type Lock | steel grade | Weight kg | Weight Lbs |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.60 | 41.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.30 | 42.50 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.35 | 47.00 |

| 6'4"H x 3'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 18.15 | 40.00 |

| 6'4"H x 42"W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 19.00 | 42.00 |

| 6'4"H X 5'W - Walk Thru Frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 21.00 | 46.00 |

3. Mason Frame-American Type

| Name | Tube Size | Type Lock | Steel Grade | Weight Kg | Weight Lbs |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 15.00 | 33.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | Drop Lock | Q235 | 20.40 | 45.00 |

| 3'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 12.25 | 27.00 |

| 4'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 15.45 | 34.00 |

| 5'H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 16.80 | 37.00 |

| 6'4''H X 5'W - Mason frame | OD 1.69" thickness 0.098" | C-Lock | Q235 | 19.50 | 43.00 |

4. Snap On Lock Frame-American Type

| Dia | width | Height |

| 1.625'' | 3'(914.4mm)/5'(1524mm) | 4'(1219.2mm)/20''(508mm)/40''(1016mm) |

| 1.625'' | 5' | 4'(1219.2mm)/5'(1524mm)/6'8''(2032mm)/20''(508mm)/40''(1016mm) |

5.Flip Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 2'1''(635mm)/3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm) |

6. Fast Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 42''(1066.8mm) | 6'7''(2006.6mm) |

7. Vanguard Lock Frame-American Type

| Dia | Width | Height |

| 1.69'' | 3'(914.4mm) | 5'(1524mm)/6'4''(1930.4mm) |

| 1.69'' | 42''(1066.8mm) | 6'4''(1930.4mm) |

| 1.69'' | 5'(1524mm) | 3'(914.4mm)/4'(1219.2mm)/5'(1524mm)/6'4''(1930.4mm) |

Advantages

1.The entire product range and customization capabilities

Full range of models: We produce the world's mainstream frame-type scaffolding, including standard main frames, H-shaped frames, ladder frames, passageway frames, masonry frames and various other types, as well as various locking systems (quick locks, flip locks, Pioneer locks, etc.).

Customization to depth: Based on the customer's design drawings and specific requirements, we can produce various non-standard frames and provide a one-stop solution.

2. Outstanding quality and durability

High-quality steel: Utilizing different grades of steel such as Q195, Q235, and Q355 to ensure the structural integrity and strong load-bearing capacity of the product.

Diverse surface treatments: Offer a variety of anti-corrosion treatment processes such as powder coating, pre-zinc plating, and hot-dip zinc plating, significantly extending the service life of the products in harsh environments and meeting the durability standards of different markets worldwide.

3. Efficiently integrated production and supply

Complete industrial chain: Located in Tianjin, the largest steel and scaffolding production base in China, it possesses a complete processing and production chain from raw materials to finished products, ensuring stable production capacity and strict quality control.

Logistics geographical advantage: Leveraging Tianjin's position as an important port city, maritime logistics is both convenient and efficient, enabling the rapid and cost-effective delivery of goods to all parts of the world.

4. Extensive market validation and reliability

Global export experience: The product has successfully been exported to multiple markets such as Southeast Asia, the Middle East, Europe, and the Americas. Through practical tests in various regions and projects, its reliability and adaptability have been proven.

Systematic assembly: Provides a complete set of components including frames, cross braces, bases, U-shaped top supports, hook pedals, and connecting pins. The system has good compatibility and ensures safe and efficient assembly.

5. Customer-centered service concept

Core principle: Adhere to the business philosophy of "Quality First, Customer Supreme, Ultimate Service".

Commitment: Dedicated to meeting customer needs, focused on establishing and promoting mutually beneficial long-term partnerships, and providing comprehensive pre-sale, in-sale and after-sale support services.

FAQs

1. Q: What types of frame scaffolding can you provide?

A: We specialize in manufacturing a wide range of frame scaffolding types to meet diverse project needs. Our portfolio includes Main Frames, H Frames, Ladder Frames, Walk-through Frames, Mason Frames, and various locking systems such as Snap-on Lock, Flip Lock, Fast Lock, and Vanguard Lock frames. We produce all types based on customer specifications and drawings.

2. Q: What are your product specifications regarding material and surface treatment?

A: Our scaffolding frames are made from high-grade steel (Q195, Q235, Q355) to ensure strength and durability. We offer multiple surface treatment options for corrosion protection, including Powder Coating, Pre-galvanization, and Hot-dip Galvanization, catering to different environmental and project requirements.

3. Q: Where are your products manufactured, and what are your logistics advantages?

A: Our factory, Tianjin Huayou Scaffolding Co., Ltd., is located in Tianjin City—a major hub for steel and scaffolding manufacturing in China. Being a key port city, Tianjin offers excellent logistics, making it efficient and cost-effective to ship our products to global destinations, including Southeast Asia, the Middle East, Europe, and the Americas.

4. Q: What markets do you currently serve?

A: We have successfully exported our scaffolding products to a wide range of international markets. Our current export destinations include countries across Southeast Asia, the Middle East, Europe, and the Americas, demonstrating our capability to meet diverse regional standards and project demands.

5. Q: What is your company's core business philosophy?

A: Our guiding principle is "Quality First, Customer Foremost, and Service Utmost." We are committed to providing high-quality products, prioritizing customer needs, and delivering exceptional service. Our complete in-house processing and production chain ensures we can flexibly meet your specific requirements and foster mutually beneficial, long-term cooperation.