Multi-Functional Metal Pipe Scaffolding Solution

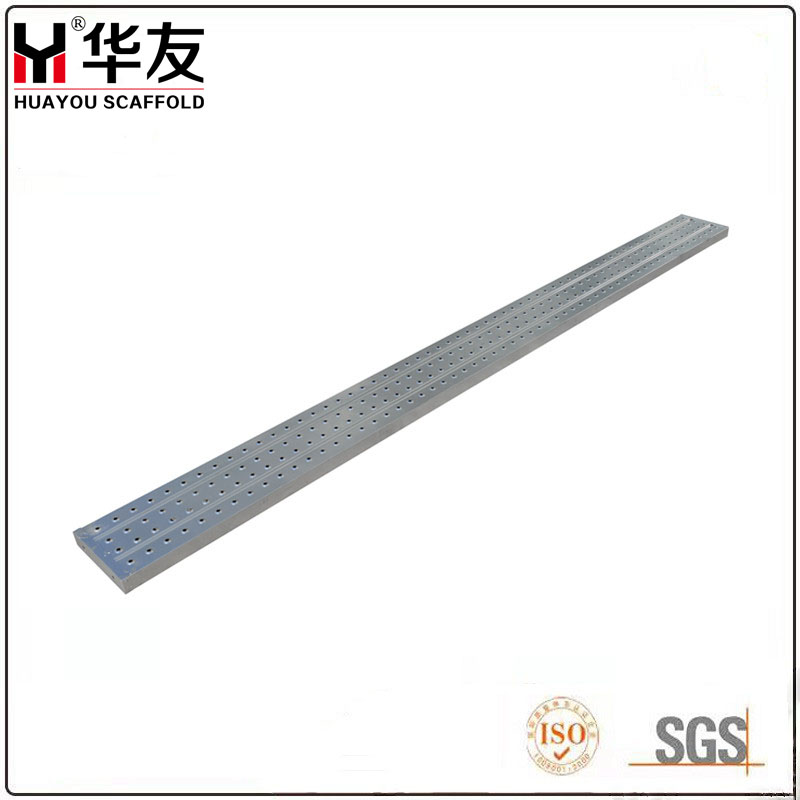

With over a decade of expertise in scaffolding manufacturing and export, we are a leading Chinese supplier trusted by clients in over 50 countries. Our heavy-duty steel scaffold planks, also known as metal decks or walk boards, are engineered for maximum durability, safety, and load-bearing capacity—ideal for construction, shipbuilding, and oil & gas projects worldwide. Featuring anti-slip surfaces, pre-drilled M18 bolt holes for secure connections, and compatibility with toe boards, our hot-dip galvanized steel plates meet and exceed industry standards for high-altitude work platforms. Rigorously tested and QC-checked from raw materials to finished products, these versatile metal boards seamlessly integrate with tubular scaffolding systems across residential, commercial, and industrial applications. Backed by monthly 3,000-ton raw material reserves, we deliver reliable scaffolding solutions that keep global worksites productive and accident-free.

Size as following

|

Southeast Asia Markets |

|||||

|

Item |

Width (mm) |

Height (mm) |

Thickness (mm) |

Length (m) |

Stiffener |

|

Metal Plank |

200 |

50 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

210 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

240 |

45 |

1.0-2.0mm |

0.5m-4.0m |

Flat/box/v-rib |

|

|

250 |

50/40 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

300 |

50/65 |

1.0-2.0mm |

0.5-4.0m |

Flat/box/v-rib |

|

|

The Middle east Market |

|||||

|

Steel Board |

225 |

38 |

1.5-2.0mm |

0.5-4.0m |

box |

|

Australian Market For kwikstage |

|||||

| Steel Plank | 230 | 63.5 | 1.5-2.0mm | 0.7-2.4m | Flat |

| European Markets for Layher scaffolding | |||||

| Plank | 320 | 76 | 1.5-2.0mm | 0.5-4m | Flat |

Products Advantages

1. Unmatched Durability & Strength – Made from high-quality steel with rigorous QC checks, our scaffold planks withstand heavy-duty use in construction, shipbuilding, and oil/gas industries.

2. Superior Safety & Stability – Anti-slip surface, reinforced load capacity, and compliance with international standards ensure worker security even in harsh conditions.

3. Versatile & Adaptable Design – Pre-drilled M18 bolt holes and toe board compatibility allow easy assembly and adjustable platform widths for various scaffolding systems.

4. Global Reliability – Trusted in 50+ countries, our steel planks (also called metal decks, walkboards, or scaffold boards) are ideal for commercial, industrial, and marine projects.

5. Efficient Production & Supply – With 3,000 tons of raw material stocked monthly, we guarantee consistent quality and timely delivery worldwide.

FAQS

1. What are the core advantages of your scaffolding steel plates?

Huayou steel plates are made of high-quality steel, featuring an anti-slip surface, ultra-high load capacity (meeting international standards), and are suitable for various harsh construction environments (such as shipbuilding, oil platforms, etc.). A monthly raw material reserve of 3,000 tons ensures a stable supply, and long-term cooperation with customers from over 50 countries has verified its reliability.

2. How can the anti-slip performance of steel plates be guaranteed?

The surface of each steel plate has undergone special anti-slip treatment (such as embossing patterns or galvanizing processes), which can provide strong friction even in damp, oily and other conditions, significantly reducing the risk of slipping on construction sites.

3. How are steel plates connected to other scaffolding components?

The standard product is pre-installed with M18 bolt holes, which can be quickly fixed to other steel plates or toe plates (with black and yellow warning colors). It is used in conjunction with scaffolding pipes and couplers, and the platform width can be flexibly adjusted. After installation, it must pass strict acceptance.

4. In which fields and markets is it mainly applied?

It is widely used in the construction industry, ship repair, power engineering and oil platforms, and is mainly exported to markets in Asia, the Middle East, Australia and the Americas. It is suitable for both temporary scaffolding and long-term heavy projects.

5. How can the quality of raw materials and finished products be ensured?

From raw materials (chemical composition, surface inspection) to finished products, we implement full-process QC control. We reserve 3,000 tons of qualified steel every month to ensure that each batch of products meets industry standards and provide relevant certification support.