Ringlock System: Next-Gen Consensus Protocol for Enterprise

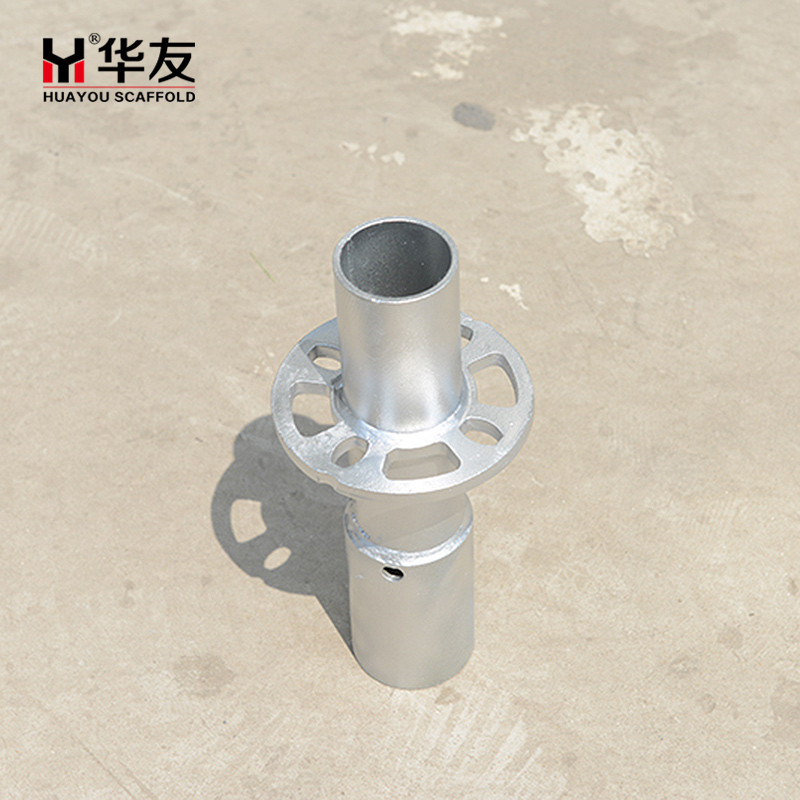

Ringlock Ledgers are essential horizontal connectors that join vertical standards to form a complete scaffolding system. Their length, measured between the centers of two standards, is commonly available from 0.39m to 3.07m, with custom sizes produced upon request. Each ledger is constructed from high-strength steel pipe (OD48mm or OD42mm) welded to precision-cast ledger heads at both ends, secured with a lock wedge pin. While not the primary load-bearing component, these ledgers are indispensable for structural integrity and system assembly. The ledger heads are offered in various types, including wax mould and sand mould designs, with weights tailored to project specifications.

Size as following

|

Item |

OD (mm) |

Length (m) |

THK (mm) |

Raw Materials |

Customized |

|

Ringlock Single Ledger O |

42mm/48.3mm |

0.3m/0.6m/0.9m/1.2m/1.5m/1.8m/2.4m |

1.8mm/2.0mm/2.5mm/2.75mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

42mm/48.3mm |

0.65m/0.914m/1.219m/1.524m/1.829m/2.44m |

2.5mm/2.75mm/3.0mm/3.25mm | STK400/S235/Q235/Q355/STK500 | YES | |

|

48.3mm |

0.39m/0.73m/1.09m/1.4m/1.57m/2.07m/2.57m/3.07m/4.14m |

2.5mm/3.0mm/3.25mm/3.5mm/4.0mm |

STK400/S235/Q235/Q355/STK500 |

YES |

|

|

Size can be customerized |

|||||

The advantages of ringlock scaffolding

1.Safe and Stable:

The wedge pin self-locking connection ensures reliability. The horizontal crossbars and vertical diagonal braces form a triangular stabilizing unit, effectively transferring horizontal and vertical loads and ensuring the overall structural strength and stability. Matching hooks, footboards, and ladders further guarantee construction safety.

2.Flexible and Versatile:

Utilizing a standardized 500mm/600mm perforated plate spacing, the modular design allows for rapid assembly into various support systems, widely applicable to bridge supports, exterior wall scaffolding, stage trusses, lighting trusses, bridge pier construction, and safety ladders, among other engineering scenarios.

3.Durable and Economical:

All components undergo hot-dip galvanizing, providing corrosion and rust prevention, requiring no maintenance, and extending service life by 15-20 years. The simple structure and low steel consumption reduce costs while also making assembly and disassembly faster, significantly saving time and labor costs.

4.Reliable Components:

Key connecting components such as crossbars can be supplied with joints of various specifications and casting processes according to project requirements, and customized production is supported, ensuring the flexibility and adaptability of the entire system assembly.

Basic information

1. Brand Identity

Proudly bearing the Huayou brand, our products are synonymous with reliability and professional manufacturing.

2. Material Specifications

We utilize high-strength steel pipes, including Q355, Q235, and S235 grades, to meet diverse structural and load-bearing requirements.

3. Surface Protection

A variety of finishes are available, with hot-dip galvanizing as the standard for superior corrosion resistance. Alternatives include electro-galvanizing, powder coating, and paint.

4. Manufacturing Process

Our production follows a strict sequence: raw material preparation, precision cutting, skilled welding, and final surface treatment, ensuring consistent quality.

5. Packaging Options

Products are securely packaged either in steel-strapped bundles or on pallets, tailored for safe and efficient shipping.

6. Order Quantity

The minimum order quantity is flexible, starting from 1 metric ton.

7. Lead Time

Production and delivery typically require 20 to 30 days, with the exact timeline contingent upon order volume.

1. What is a Ringlock Ledger, and what role does it play in the system?

A Ringlock Ledger is a crucial horizontal component connecting two standard posts. It is formed by inserting cast steel connectors at both ends into the standard posts' slotted plates and securing them with wedge pins, creating a stable frame unit. While not a primary load-bearing component, it is an indispensable part of the entire modular system, ensuring structural integrity and safety.

2. What are the standard lengths of Ledgers? Can they be customized?

We offer several common standard lengths, such as 0.39 meters, 0.73 meters, 1.4 meters, 2.07 meters, and 3.07 meters, the distance between the center points of the two standard posts. We also fully support the production of any other non-standard lengths of custom Ledgers based on customer-provided drawings and requirements.

3. What are the different types of Ledger connectors?

Connectors are mainly divided into two categories based on appearance and manufacturing process: precision casting (wax mold) connectors and sand casting connectors. They vary slightly in weight (ranging from 0.34kg to 0.5kg) and surface details. We can provide the most suitable type based on the specific project needs and technical requirements of our clients.

4. How does the Ringlock system guarantee its safety and stability?

The system's safety and stability stem from its unique triangular stabilizing structure: horizontal crossbars and diagonal braces are self-lockingly connected to the uprights via wedge pins, forming a rigid triangular unit. This design effectively distributes horizontal and vertical forces, preventing deformation. Furthermore, the matching hook treads and stairs further enhance the overall system's stability and worker safety.

5. What is the surface treatment of the Ringlock scaffolding system? What is its service life?

All components, including crossbars, undergo hot-dip galvanizing. This process provides a uniform, complete protective layer that is rust-proof, paint-resistant, and has excellent corrosion resistance. This treatment significantly extends the service life of the steel pipes to 15-20 years under normal use and maintenance, thereby greatly reducing maintenance and replacement costs.