Robust And Durable Scaffolding Tube & Coupler Connectors Provide Reliable Support

Description

Scaffolding steel pipe, also known as steel tube, serves as fundamental material for both temporary structures and the manufacturing of advanced systems like ringlock and cuplock. It is extensively applied across construction, shipbuilding, and offshore engineering for its reliability and strength. Unlike traditional bamboo, steel tubes offer superior safety, durability, and stability, making them the preferred choice in modern construction. Typically produced as Electrical Resistance Welded pipes with an outer diameter of 48.3mm and thickness ranging from 1.8mm to 4.75mm, they ensure high performance. Our scaffolding tubes feature a premium zinc coating up to 280g, significantly enhancing corrosion resistance compared to the standard 210g.

Size as following

|

Item Name |

Surface Treament |

Outer Diameter (mm) |

Thickness (mm) |

Length(mm) |

|

Scaffolding Steel Pipe |

Black/Hot Dip Galv.

|

48.3/48.6 |

1.8-4.75 |

0m-12m |

|

38 |

1.8-4.75 |

0m-12m |

||

|

42 |

1.8-4.75 |

0m-12m |

||

|

60 |

1.8-4.75 |

0m-12m |

||

|

Pre-Galv.

|

21 |

0.9-1.5 |

0m-12m |

|

|

25 |

0.9-2.0 |

0m-12m |

||

|

27 |

0.9-2.0 |

0m-12m |

||

|

42 |

1.4-2.0 |

0m-12m |

||

|

48 |

1.4-2.0 |

0m-12m |

||

|

60 |

1.5-2.5 |

0m-12m |

Advantages

1. Versatility and wide application

Core application: As scaffolding pipes, it is widely used in various construction and engineering projects.

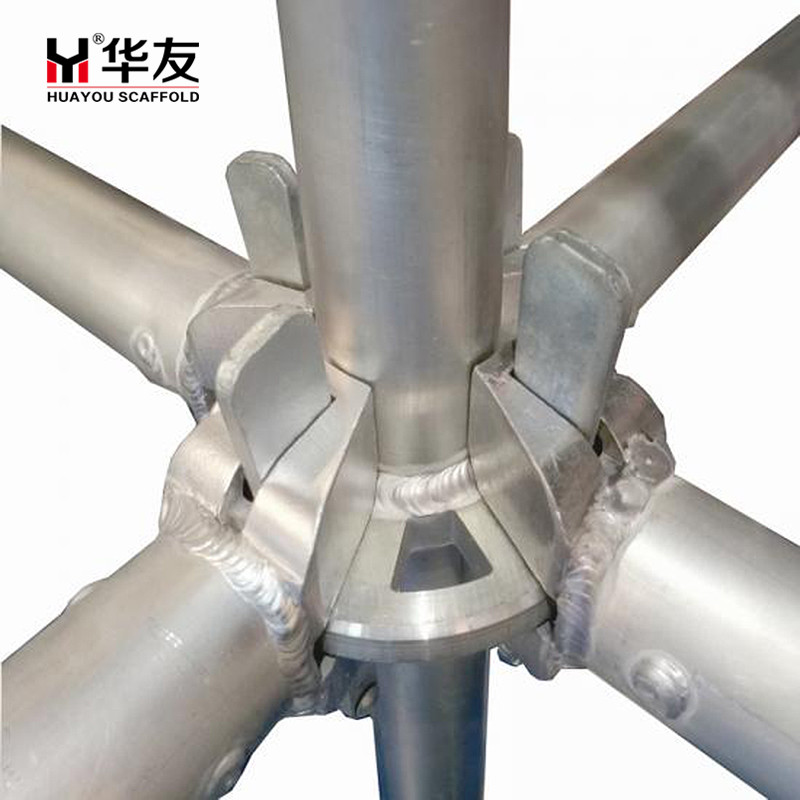

Processing base materials: They can be used as raw materials and further processed into more advanced scaffolding systems, such as Ringlock and Cuplock.

Cross-industry applications: Not only limited to the construction industry, but also widely used in multiple industrial fields such as pipeline processing, shipbuilding, network structures, Marine engineering, and oil and gas.

2. Excellent material performance and safety

High strength and durability: Compared with traditional bamboo scaffolding, steel pipes have higher strength, stability and durability, which can better ensure construction safety and are the first choice for modern construction.

Strict material standards: Multiple steel grades such as Q235, Q355/S235 are selected, in compliance with international standards like EN, BS, and JIS, ensuring reliable material quality.

High quality requirements: The surface of the pipe is smooth, free of cracks and bends, and not prone to rust, meeting national material standards.

3. Standardization of specifications and compatibility

General specification: The most commonly used steel pipe has an outer diameter of 48.3mm, with a thickness range covering 1.8mm to 4.75mm. This is a globally recognized standard specification.

System compatibility: Specifically designed for use with scaffolding couplings (pipe buckle system), it offers flexible erection and stable connection.

4. Excellent anti-corrosion treatment (core competitive advantage)

Ultra-high zinc coating anti-corrosion: It offers a hot-dip galvanized coating of up to 280g/㎡, far exceeding the common industry standard of 210g/㎡. This greatly extends the service life of the steel pipe, providing excellent corrosion resistance even in harsh environments, reducing maintenance costs and replacement frequency.

5. Flexible surface treatment options

We offer a variety of surface treatment methods to meet the diverse needs of different customers, including hot-dip galvanizing, pre-galvanizing, black pipe and painting, providing customers with more options and cost control space.

Basic information

Huayou is a leading supplier of high-quality scaffolding steel pipes, widely used in construction and various industrial projects. Our steel tubes, made from materials like Q235 and Q345, comply with international standards including EN39 and BS1139. Featuring a durable high-zinc coating up to 280g for superior corrosion resistance, they are essential for both traditional tube-and-coupler systems and advanced scaffolding solutions like ringlock and cuplock. Trust Huayou for reliable, safe, and versatile steel pipes that meet the highest demands of modern engineering.