Aluminum Ringlock Is Easy To Install And Widely Used

Product Introduction

Made from premium aluminum alloy (T6-6061), our scaffolding is 1.5 to 2 times stronger than traditional carbon steel tube scaffolding. The superior strength ensures excellent stability and safety, making it ideal for projects of all sizes.

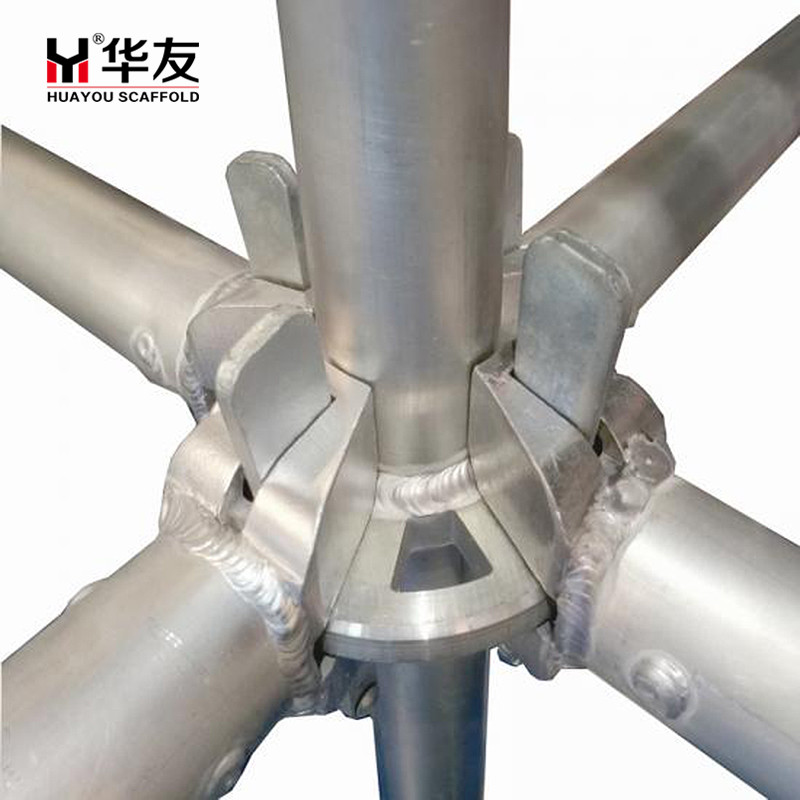

One of the highlights of our aluminum alloy disc scaffolding is its easy installation. It features a user-friendly design and can be quickly assembled and disassembled, saving you valuable time on the construction site. Whether you are an experienced contractor or a DIY enthusiast, you will appreciate the ease of setting up our scaffolding, allowing you to focus on what is really important - getting the job done efficiently.

Our aluminum alloy scaffolding is not only durable and easy to install, but also widely used in a variety of industries. From construction sites to maintenance projects, its versatility makes it the first choice of professionals around the world.

Since our establishment in 2019, we have been committed to expanding the market. Now our products have covered nearly 50 countries around the world and are deeply trusted by customers. We have established a complete procurement system to ensure that customers get the best quality products and services.

Main feature

This innovative scaffolding system is made of high-quality aluminum alloy (T6-6061), which is 1.5 to 2 times stronger than traditional carbon steel pipes. This outstanding feature not only enhances the overall stability of the scaffolding, but also ensures that it can withstand the harsh construction environment.

The aluminum scaffolding system is designed with versatility in mind. Its modular design makes it easy to assemble and disassemble, making it ideal for projects of all sizes. Whether you are working on a small residential renovation or a large commercial construction site, aluminum scaffolding can be adjusted to your specific needs. The lightweight nature of aluminum also makes it easier to transport and handle, reducing labor costs and increasing on-site efficiency.

Product Advantage

One of the main advantages of aluminium ringlock scaffolding is its light weight. This feature not only makes it easier to transport and assemble, but also reduces the physical burden on workers during installation.

In addition, the corrosion resistance of aluminum ensures a longer service life for the scaffolding, minimizing maintenance costs and downtime. The modular design of the ring-lock system allows for quick adjustment and configuration to meet various project needs.

Product shortcoming

The initial cost of aluminum scaffolding can be higher than traditional steel scaffolding, which may be prohibitive for some budget-conscious contractors.

In addition, while aluminum is strong, it may not be suitable for all applications, especially in environments that need to withstand extreme loads or heavy loads.

FAQS

Q1. What is aluminum alloy disc buckle scaffolding?

Aluminum alloy disc buckle scaffolding is a modular scaffolding system made of aluminum alloy, easy to assemble and disassemble. Its unique disc buckle mechanism allows for quick adjustment and safe connection.

Q2. How does it compare to traditional scaffolding?

Compared with traditional carbon steel scaffolding, aluminum alloy buckle scaffolding is stronger, lighter and more corrosion-resistant, making it an ideal choice for indoor and outdoor applications.

Q3. Is it suitable for all types of construction projects?

Yes! Aluminum scaffolding is very versatile and can be used in a variety of construction projects including residential, commercial and industrial applications.

Q4. What are the safety features?

The design of the Aluminum Ring Lock Scaffold includes features such as a non-slip platform, a safety locking mechanism and a stable base to ensure maximum safety for workers working at height.

Q5. How to maintain the aluminum scaffolding?

Regular inspection for wear, cleaning of debris, and proper storage when not in use will help maintain the integrity and longevity of your scaffolding system.