Formwork

-

P80 Plastic Formwork

The Plastic Formwork is made of PP or ABS materials. That will have very high reusable for different type projects, especially Walls, Columns and Foundations projects etc.

Plastic Formwork also have other advantages, light weight, cost-effective, resistant moisture and durable base on concrete construction. Thus, all our working efficiency will be fast and reduce more labour cost.

This formwork system include formwork panel, handel, waling , tie rod and nut and panel strut etc.

-

Formwork accessories Pressed Panel Clamp

BFD Alignment Formwork Clamp for Peri Formwork Panel Maximo and Trio, also use for steel structure formwork. The clamp or clip mainly fixed between steel formworks together and more stronger like the teeth when pour concrete. Normally, the steel formwork only support wall concrete and column concrete. so the formwork clamp widely be used.

For formwork pressed clip, we also have two different quality.

One is the claw or teeth use Q355 steel, the other is the claw or teeth use Q235.

-

Formwork Casted Panel lock clamp

Formwork Casted clamp mainly use for steel Euro Form system. its function to fix two steel forms joint well and to support slab form, wall form etc.

Casting clamp that means all production process are different from pressed one. We use high quality and pure raw materials to be heated and melted, then pour molten iron into mold. then cooling and solidification, then polishing and grinding then make electro-galvanized then assemble them and packing.

We can ensure all goods with well quality.

-

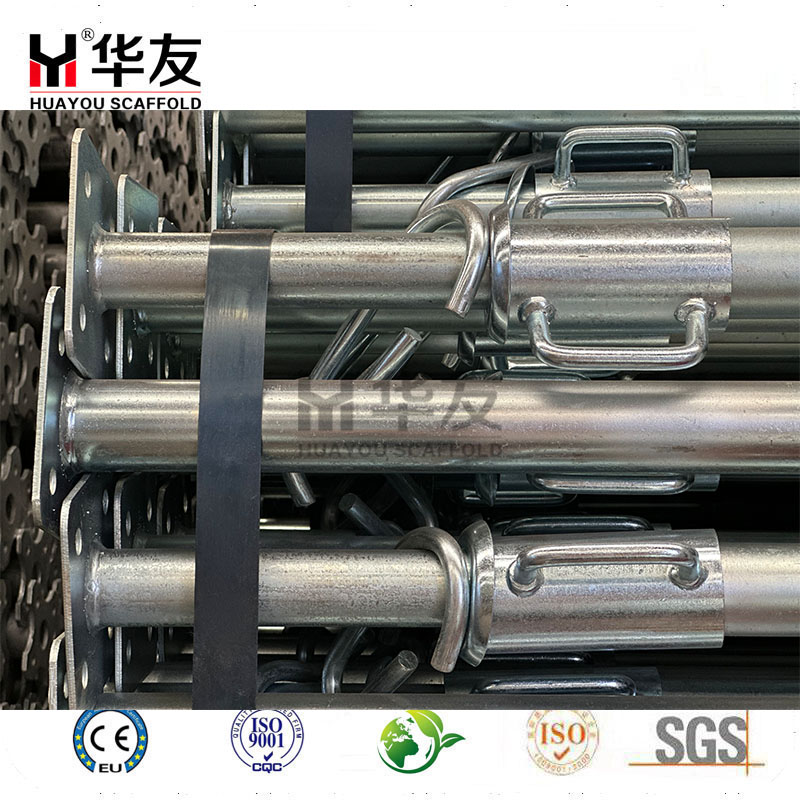

Light Duty Scaffolding steel prop

Scaffolding Steel Prop, also called prop, shoring etc. Normally we have two type, one is Light duty prop is made by small sizes of scaffolding pipes, such as OD40/48mm, OD48/57mm for producing the inner pipe and outer pipe of scaffolding prop.The nut of light duty prop we call cup nut that the shape just like a cup. It is light weight compare with heavy duty prop and usually painted, pre-galvanized and electro-galvanized by surface treatment.

The other is heavy duty prop, the difference is Pipe diameter and thickness, nut and some other accessoires. such as OD48/60mm, OD60/76mm, OD76/89mm even more bigger, thickness most use above 2.0mm. Nut is casting or drop forged with more weight.

-

Polypropylene Plastic PVC construction Formwork

Introducing our innovative PVC Plastic Construction Formwork, the ultimate solution for modern construction needs. Designed with durability and efficiency in mind, this formwork system is revolutionizing the way builders approach concrete pouring and structural support.

Crafted from high-quality PVC plastic, our formwork is lightweight yet incredibly strong, making it easy to handle and transport on-site. Unlike traditional wooden or metal formwork, our PVC option is resistant to moisture, corrosion, and chemical damage, ensuring a longer lifespan and reduced maintenance costs. This means you can focus on your project without worrying about wear and tear.

PP Formwork is a recycle formwork with more than 60 times, even in China, we can reuse more than 100 times. Plastic formwork is different from plywood or steel formwork. Their hardness and loading capacity is better than plywood, and the weight is lighter than steel formwork. That is why so many projects will use plastic formwork.

Plastic Formwork have some stable size, our normal size is 1220x2440mm, 1250x2500mm, 500x2000mm, 500x2500mm. The Thickness just have 12mm, 15mm, 18mm, 21mm.

You can choose what you need base on your projects.

Available thickness: 10-21mm, max width 1250mm, others can be customized.

-

Heavy Duty Scaffolding Steel Prop

Scaffolding Steel Prop, also called prop, shoring etc. Normally we have two type, one is heavy duty prop, the difference is Pipe diameter and thickness, nut and some other accessoires. such as OD48/60mm, OD60/76mm, OD76/89mm even more bigger, thickness most use above 2.0mm. Nut is casting or drop forged with more weight.

The other is Light duty prop is made by small sizes of scaffolding pipes, such as OD40/48mm, OD48/57mm for producing the inner pipe and outer pipe of scaffolding prop.The nut of light duty prop we call cup nut that the shape just like a cup. It is light weight compare with heavy duty prop and usually painted, pre-galvanized and electro-galvanized by surface treatment.

-

Steel Euro Formwork

Steel Formwork are made by steel frame with plywood. and the steel frame have many components, for example, F bar, L bar, triangle bar ect. The normal size are 600x1200mm, 500x1200mm, 400x1200mm, 300x1200mm 200x1200mm, and 600x1500mm, 500x1500mm, 400x1500mm, 300x1500mm, 200x1500mm etc.

Steel Formwork usually be used as one whole system, not only formwork, also have in corner panel, outer corner angle, pipe and pipe support.

-

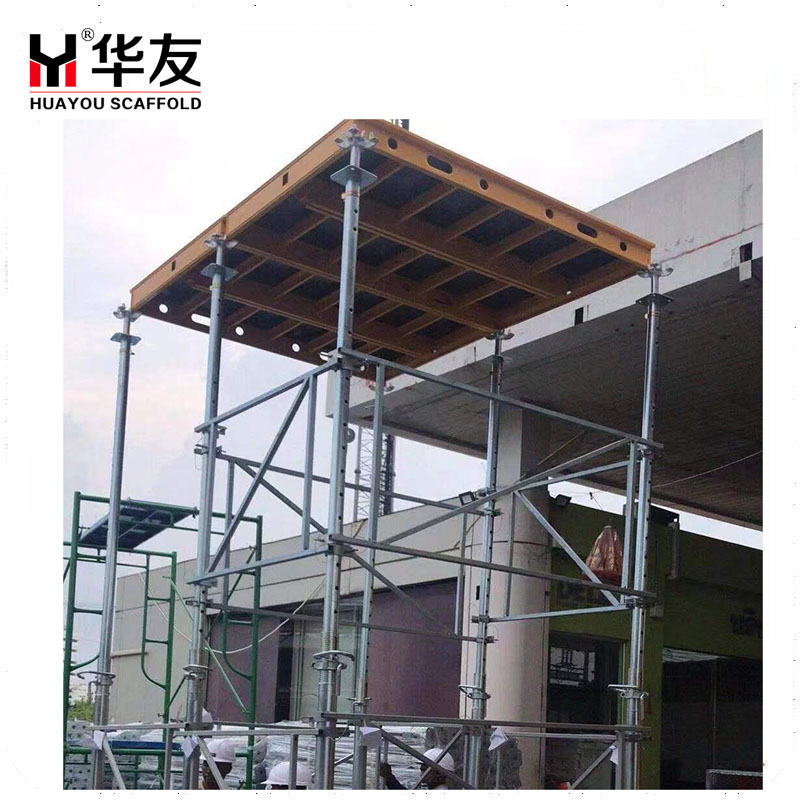

Scaffolding Props Shoring

Scaffolding Steel prop shoring are combined with heavy duty prop, H beam, Tripod and some other formwork accessories.

This scaffolding system mainly support formwork system and bear high loading capacity. In order to keep the whole system stable, the horizontal direction will be connected by steel pipe with coupler. They have the same function as scaffolding steel prop.

-

Scaffolding Prop Fork Head

Scaffolding fork Head jack have 4 pcs pillars which are produced by angle bar and base plate together. it is very important part for prop to connect H beam to support formwork concrete and maintain the overall stability of the scaffolding system.

Usually made of high-strength steel, it matches the material of scaffolding steel supports, ensuring good load-bearing capacity. In use, it enables easy and quick installation, helping improve scaffolding assembly efficiency. Meanwhile, its four-corner design enhances connection firmness, effectively preventing component loosening during scaffolding use. Qualified four-corner plugs also meet relevant construction safety standards, providing a reliable guarantee for workers’ safe operation on the scaffolding.