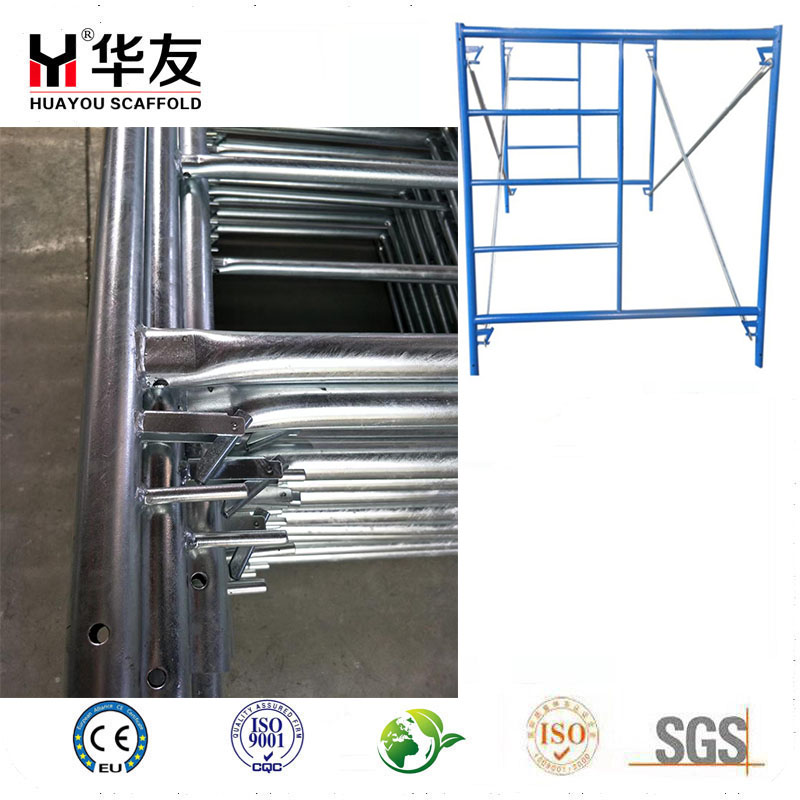

Sturdy And Durable Tubular Scaffolding

Scaffolding Frames

1. Scaffolding Frame Specification-South Asia Type

| Name | Size mm | Main Tube mm | Other Tube mm | steel grade | surface |

| Main Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1524 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 914x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| H Frame | 1219x1930 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. |

| 1219x1700 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x1219 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| 1219x914 | 42x2.4/2.2/1.8/1.6/1.4 | 25/21x1.0/1.2/1.5 | Q195-Q235 | Pre-Galv. | |

| Horizontal/Walking Frame | 1050x1829 | 33x2.0/1.8/1.6 | 25x1.5 | Q195-Q235 | Pre-Galv. |

| Cross Brace | 1829x1219x2198 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | |

| 1829x914x2045 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1928x610x1928 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x1219x1724 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. | ||

| 1219x610x1363 | 21x1.0/1.1/1.2/1.4 | Q195-Q235 | Pre-Galv. |

2. Fast Lock Frame-American Type

| Dia | Width | Height |

| 1.625'' | 3'(914.4mm) | 6'7''(2006.6mm) |

| 1.625'' | 5'(1524mm) | 3'1''(939.8mm)/4'1''(1244.6mm)/5'1''(1549.4mm)/6'7''(2006.6mm) |

| 1.625'' | 42''(1066.8mm) | 6'7''(2006.6mm) |

3. Vanguard Lock Frame-American Type

| Dia | Width | Height |

| 1.69'' | 3'(914.4mm) | 5'(1524mm)/6'4''(1930.4mm) |

| 1.69'' | 42''(1066.8mm) | 6'4''(1930.4mm) |

| 1.69'' | 5'(1524mm) | 3'(914.4mm)/4'(1219.2mm)/5'(1524mm)/6'4''(1930.4mm) |

Core advantages

1. Diversified product lines

We offer a full range of frame scaffolding (main frame, H-shaped frame, ladder frame, walking frame, etc.) and various locking systems (flip lock, quick lock, etc.) to meet different engineering requirements. We support customization according to drawings to satisfy the differentiated needs of global customers.

2. High-specification materials and processes

Made of Q195-Q355 grade steel and combined with surface treatment technologies such as powder coating and hot-dip galvanizing, the product ensures corrosion resistance, high strength, significantly extends service life and guarantees construction safety.

3. Advantages of vertical production

We have built a complete processing chain, with integrated control from raw materials to finished products to ensure stable quality and efficient delivery. Relying on the resources of the Tianjin steel Industry Base, we have strong cost competitiveness.

4. Global logistics is convenient

The company is located in the port city of Tianjin, with a prominent advantage in maritime transportation. It can respond quickly to international orders and cover multiple regional markets such as Southeast Asia, the Middle East, Europe and America, reducing customers' transportation costs.

5. Dual certification for quality and service

Adhering to the principle of "Quality First, Customer Supreme", through market validation in multiple countries, we provide full-process services from production to after-sales, and establish long-term mutually beneficial cooperation.

FAQS

1. What is a frame scaffolding system?

A frame scaffolding system is a temporary structure used to support a working platform for construction and maintenance projects. It provides a safe and stable environment for workers to perform tasks at different heights.

2. What are the main components of a frame scaffolding system?

The main components of a frame scaffolding system include the frame itself (which can be divided into several types such as main frame, H-frame, ladder frame and through frame), cross braces, bottom jacks, U-head jacks, wooden boards with hooks and connecting pins.

3. Can the frame scaffolding system be customized?

Yes, frame scaffolding systems can be customized based on customer requirements and specific project drawings. Manufacturers can produce various types of frames and components to meet the unique needs of different markets.

4. What types of projects can benefit from using a frame scaffolding system?

Frame scaffolding systems are versatile and can be used in a variety of projects including residential and commercial construction, maintenance works and renovations. They are particularly useful around buildings to provide safe access for workers.

5. How is the production process of the frame scaffolding system managed?

The production process of the frame scaffolding system covers the complete processing and production chain to ensure quality and efficiency. Manufacturers work closely with customers to understand their needs and produce scaffolding systems that comply with industry standards and safety regulations.